Method for directly preparing mercury oxide from mercury-containing organic sludge

A technology of organic sludge and mercury oxidation, which is applied in the fields of mercury oxidation, chemical instruments and methods, sludge treatment, etc. The effect of solving the problem of resource utilization, conducive to occupational protection and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

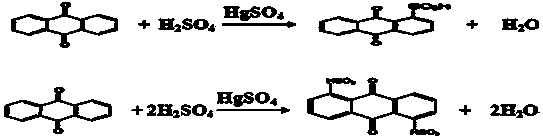

Method used

Image

Examples

Embodiment 1

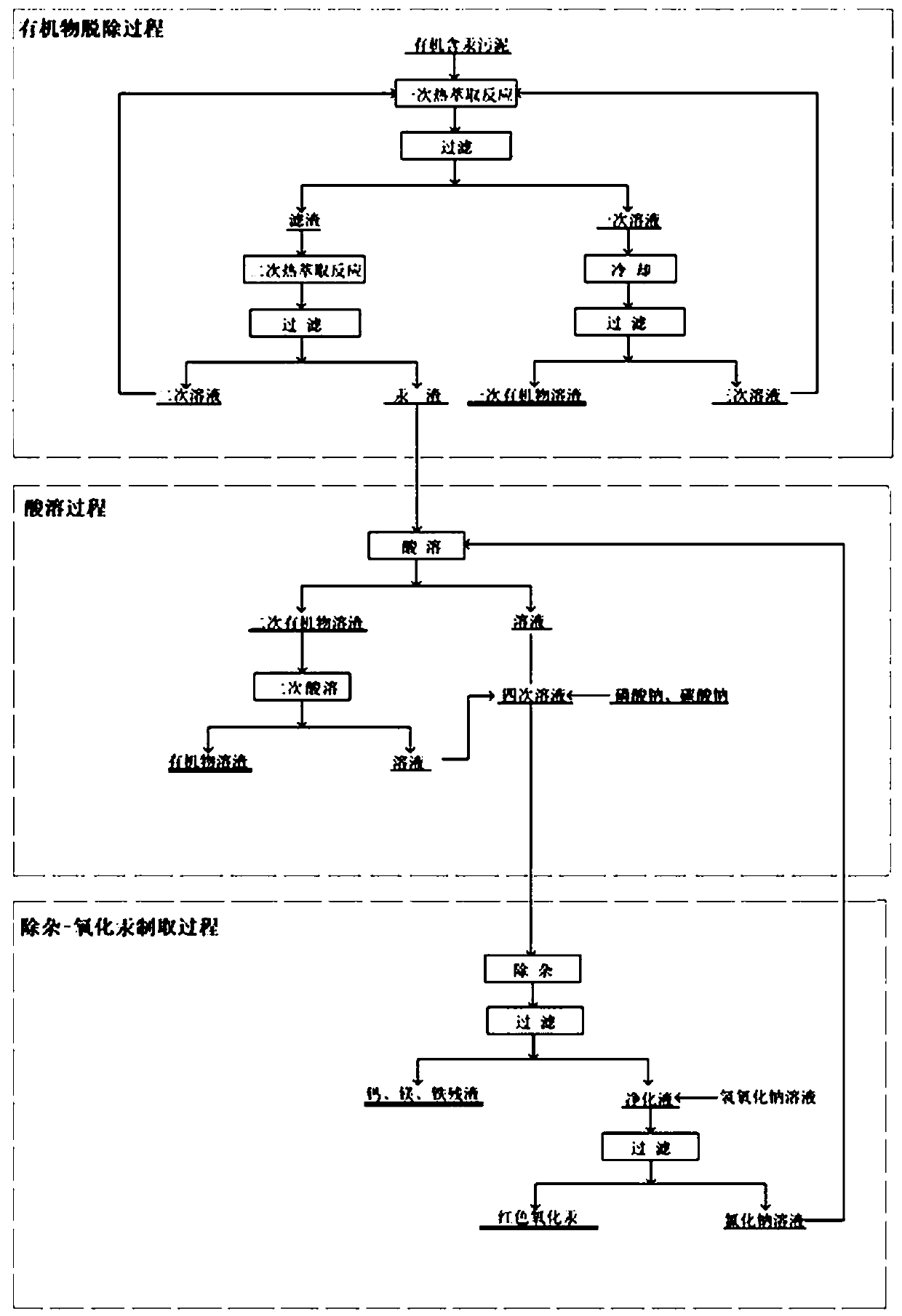

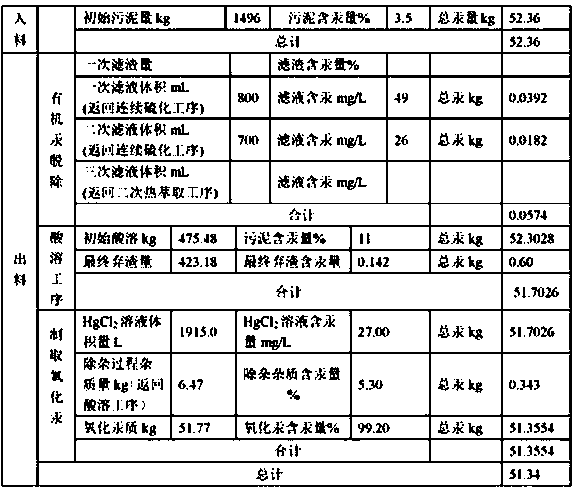

[0073] S1 organic matter removal process;

[0074] S1.1, the pre-removal step of organic matter: take 100g of the above organic mercury-containing sludge and dissolve it in warm water at 90°C according to the mass ratio of liquid to solid ratio of 2:1, keep the solution temperature at 68°C, heat extraction and shaking for 30min, and carry out vacuum heating Suction filtration, keeping the hot filtration temperature between 55 and 56°C; 277g of primary filtrate and 22.95g of primary filter residue were obtained. The removal rate of organic matter is over 90%.

[0075] S1.2, primary filter residue treatment steps: dissolve the primary filter residue in warm water at a liquid-solid ratio of 1:1, keep the solution temperature at 65°C to 70°C, extract with hot water and shake for 25 minutes, then carry out vacuum thermal filtration, and keep the temperature constant Lower than 55°C; wash with hot water, the temperature of hot water is 65°C, perform three washes with 3ml of water e...

Embodiment 2

[0086] This embodiment includes the following steps S1, organic matter removal process; S2, acid dissolution process; S3, impurity removal-mercuric oxide preparation process, etc. details as follows:

[0087] S1, organic matter removal process

[0088] S1.1, the pre-removal step of organic matter: Take 500g of the above organic mercury-containing sludge and dissolve it in warm water at 90°C according to the mass ratio of liquid to solid ratio of 2:1, keep the solution temperature at 70°C, heat extraction and shaking for 40min, and carry out vacuum heating Suction filtration, keep the hot filtration temperature between 55-56°C; obtain primary filtrate and primary filter residue.

[0089] S1.2, primary filter residue treatment steps: its process conditions: solution temperature 68°C, liquid-solid ratio 1:1, hot water extraction stirring time: 30min, hot filtration temperature 60°C; washing water temperature not lower than 60°C, a small amount of Wash more, the number of times ...

Embodiment 3

[0101] This embodiment includes the following steps S1, organic matter removal process; S2, acid dissolution process; S3 impurity removal-mercuric oxide preparation process, etc. details as follows:

[0102] S1, organic matter removal process;

[0103] S1.1, the pre-removal step of organic matter: take 1000g of the above organic mercury-containing sludge and dissolve it in warm water at 90°C according to the mass ratio of liquid to solid ratio of 2:1, keep the solution temperature at 68°C, heat extraction and shaking for 30min, and carry out vacuum heating Suction filtration, keep the hot filtration temperature between 55-56°C; obtain primary filtrate and primary filter residue.

[0104] S1.2, primary filter residue treatment step: the process conditions are solution temperature 68°C, liquid-solid ratio 1:1, hot water extraction stirring time: 35min, hot filtration temperature 62°C; washing water temperature 65°C, hot water washing times 5 Second, the secondary filter residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com