Method for preparing 2-ethylhexyl chloroformate through continuous flow of micro-channel reactor

A microchannel reactor, a technology of channel reactors, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, preparation of phosgene or haloformate, etc., can solve the content of by-product diisooctyl carbonate High and low purity of chlorinated ester products, inability to transfer heat in time, etc., to achieve high industrial application value, improve phosgene utilization rate and ensure the effect of phosgene utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

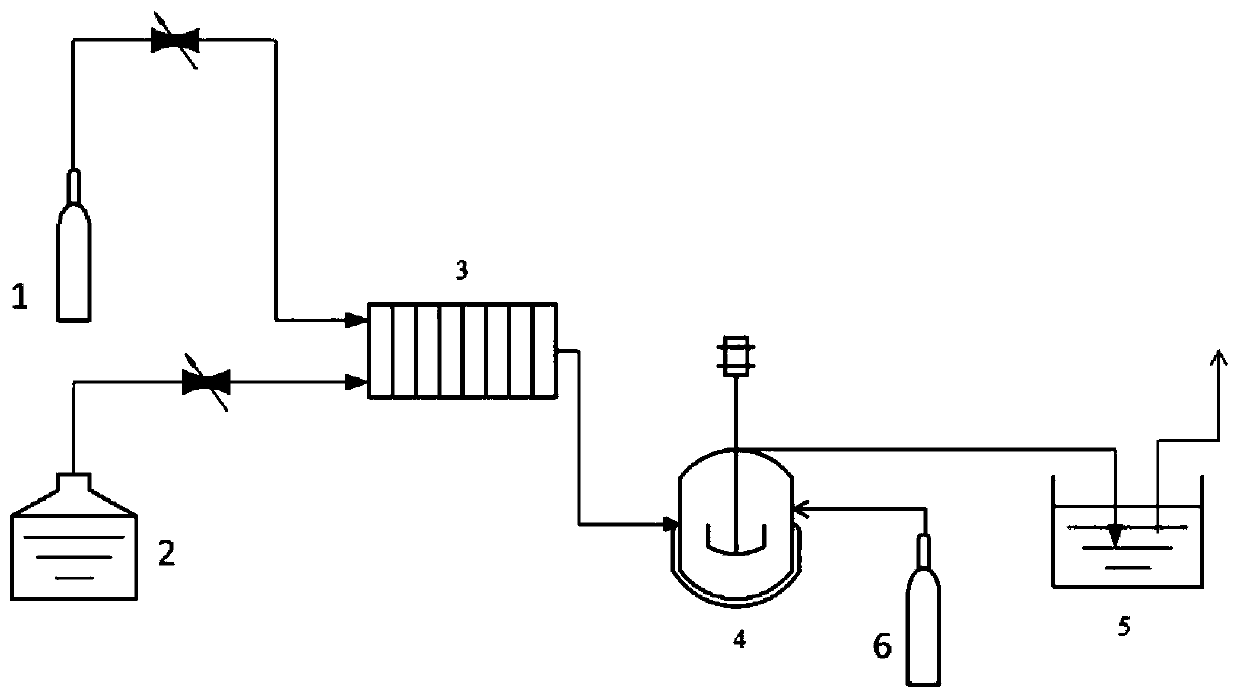

Method used

Image

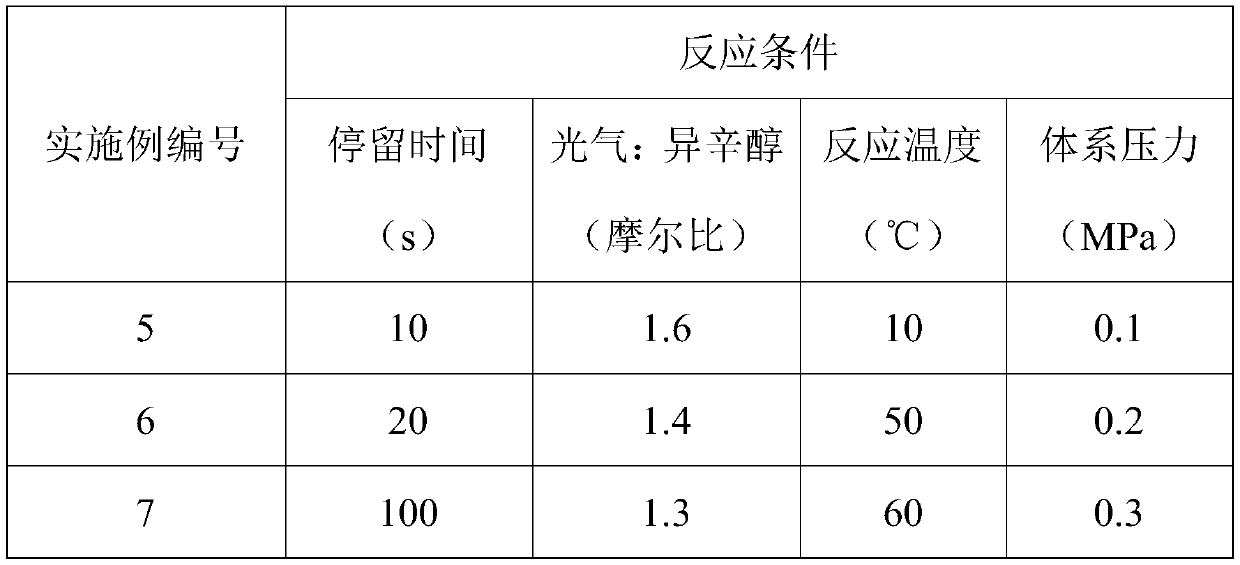

Examples

Embodiment 1

[0056] The present embodiment provides a kind of method that microchannel reactor continuous flow prepares -2-ethylhexyl chloroformate, and described method comprises the steps:

[0057] (1) According to the molar ratio 1.2:1, phosgene and isooctyl alcohol are passed into the microchannel reactor independently to react, by adjusting the back pressure valve at the reactor outlet, keep the reaction system pressure at 0.1MPa, pass through the heat exchanger To control the temperature to be 40°C, the residence time is 80s, and 2-ethylhexyl chloroformate is obtained to obtain the reaction mixture;

[0058] (2) The reaction mixture is passed into the lightening kettle, stirred and fed into nitrogen, and carried out lightening treatment to remove phosgene and hydrogen chloride until the phosgene content<50ppm, to obtain the 2-ethylhexyl chloroformate product ;

[0059] (3) Passing the tail gas after the lightening treatment into the sodium hydroxide solution for tail gas absorption,...

Embodiment 2

[0061] The present embodiment provides a kind of method that microchannel reactor continuous flow prepares -2-ethylhexyl chloroformate, and described method comprises the steps:

[0062] (1) According to the molar ratio 1.5:1, phosgene and isooctyl alcohol are passed into the microchannel reactor independently to react, by adjusting the back pressure valve at the reactor outlet, keep the reaction system pressure at 0.3MPa, pass through the heat exchanger To control the temperature to be 20°C, the residence time is 120s, and 2-ethylhexyl chloroformate is obtained to obtain the reaction mixture;

[0063] (2) The reaction mixture is passed into the lightening kettle, stirred and fed into nitrogen and argon, and carried out lightening treatment to remove phosgene and hydrogen chloride until the phosgene content<50ppm, to obtain chloroformic acid-2-ethyl Hexyl ester products;

[0064] (3) Pass the tail gas after the light removal treatment into the potassium hydroxide solution to ...

Embodiment 3

[0066] The present embodiment provides a kind of method that microchannel reactor continuous flow prepares -2-ethylhexyl chloroformate, and described method comprises the steps:

[0067] (1) According to the molar ratio 1.1:1, phosgene and isooctyl alcohol are passed into the microchannel reactor independently to react, by adjusting the back pressure valve at the reactor outlet, keep the reaction system pressure at 0.2MPa, pass through the heat exchanger To control the temperature to be 0°C, the residence time is 30s, and 2-ethylhexyl chloroformate is obtained to obtain the reaction mixture;

[0068] (2) The reaction mixture is passed into the lightening kettle, stirred and fed into nitrogen, and carried out lightening treatment to remove phosgene and hydrogen chloride until the phosgene content<50ppm, to obtain the 2-ethylhexyl chloroformate product ;

[0069] (3) passing the tail gas after the lightening treatment into the sodium carbonate solution for tail gas absorption, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com