A preparation method of high-performance seawater desalination membrane and prepared seawater desalination membrane

A high-performance, membrane technology, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc., can solve the problems of unreachable flux, high desalination rate and high flux at the same time, and reduce adsorption ability, improving anti-pollution performance, and smoothing the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-performance seawater desalination membrane, the preparation process of which is as follows:

[0030] S1. Mix 16.8% polysulfone with 83.2% N,N-dimethylformamide, stir and dissolve to form a uniform casting solution with a viscosity of 434mPa.s, let it stand for defoaming for 24 hours, and scrape the casting solution directly on the free surface with a scraper. After spinning, immerse in water to precipitate a 20-30 μm polysulfone layer, wash off the solvent to obtain a support layer membrane;

[0031] S2. Immerse the support layer membrane in step S1 in the aqueous phase solution for 20 seconds, take out and drain the residual solution on the surface, then immerse the entire membrane in the oil phase solution for interfacial polymerization reaction for 60 seconds to form a polyamide layer, and drain the residual surface solution. Then rinse with deionized water for 5 min, and pass through 6% NaHSO 3 The solution was treated for 0.5 min, and then immersed in 4% gl...

Embodiment 2

[0034]A high-performance seawater desalination membrane, the preparation process of which is as follows:

[0035] S1. Mix 16.8% polysulfone with 83.2% N,N-dimethylformamide, stir and dissolve to form a uniform casting solution with a viscosity of 434mPa.s, let it stand for defoaming for 24 hours, and scrape the casting solution directly on the free surface with a scraper. After spinning, immerse in water to precipitate a 20-30 μm polysulfone layer, wash off the solvent to obtain a support layer membrane;

[0036] S2. Immerse the support layer membrane in step S1 in the aqueous phase solution for 20 seconds, take out and drain the residual solution on the surface, then immerse the entire membrane in the oil phase solution for interfacial polymerization reaction for 60 seconds to form a polyamide layer, and drain the residual surface solution. Then rinse with deionized water for 5 min, and pass through 6% NaHSO 3 The solution was treated for 0.5 min, and then immersed in 4% gly...

Embodiment 3

[0039] A high-performance seawater desalination membrane, the preparation process of which is as follows:

[0040] S1. Mix 16.8% polysulfone with 83.2% N,N-dimethylformamide, stir and dissolve to form a uniform casting solution with a viscosity of 434mPa.s, let it stand for defoaming for 20 hours, and scrape the casting solution directly with a scraper on the After spinning, immerse in water to precipitate a 20-30 μm polysulfone layer, wash off the solvent to obtain a support layer membrane;

[0041] S2. Immerse the support layer membrane in step S1 in the aqueous phase solution for 20 seconds, take out and drain the residual solution on the surface, then immerse the entire membrane in the oil phase solution for interfacial polymerization reaction for 60 seconds to form a polyamide layer, and drain the residual surface solution. Then rinse with deionized water for 3 minutes, and pass through 6% NaHSO 3 The solution was treated for 1 min, and then immersed in 4% glycerin solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

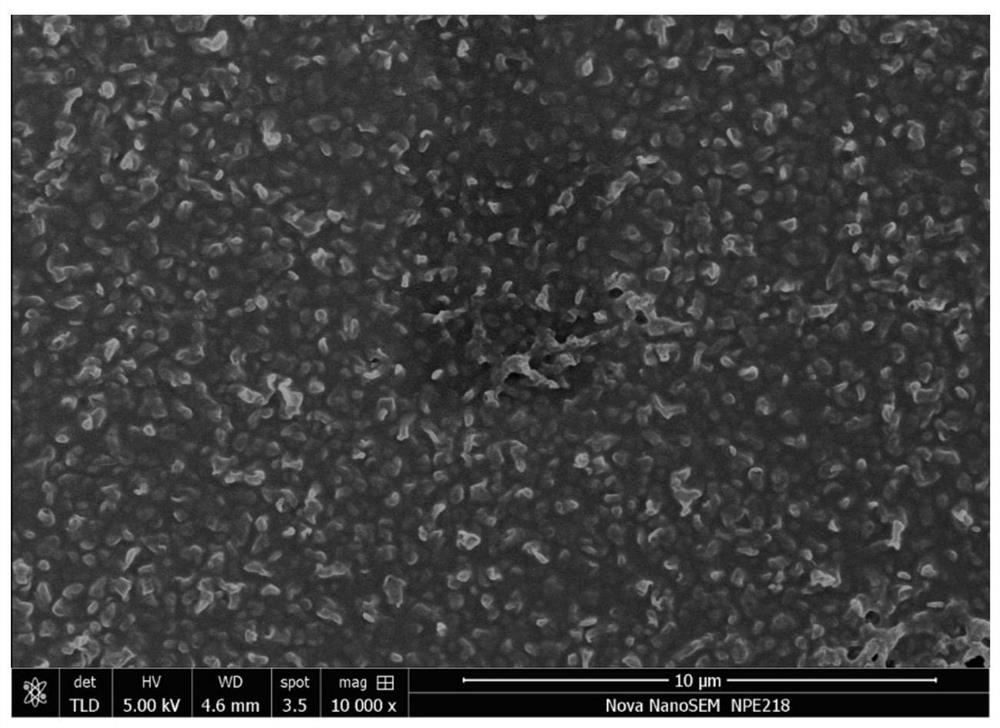

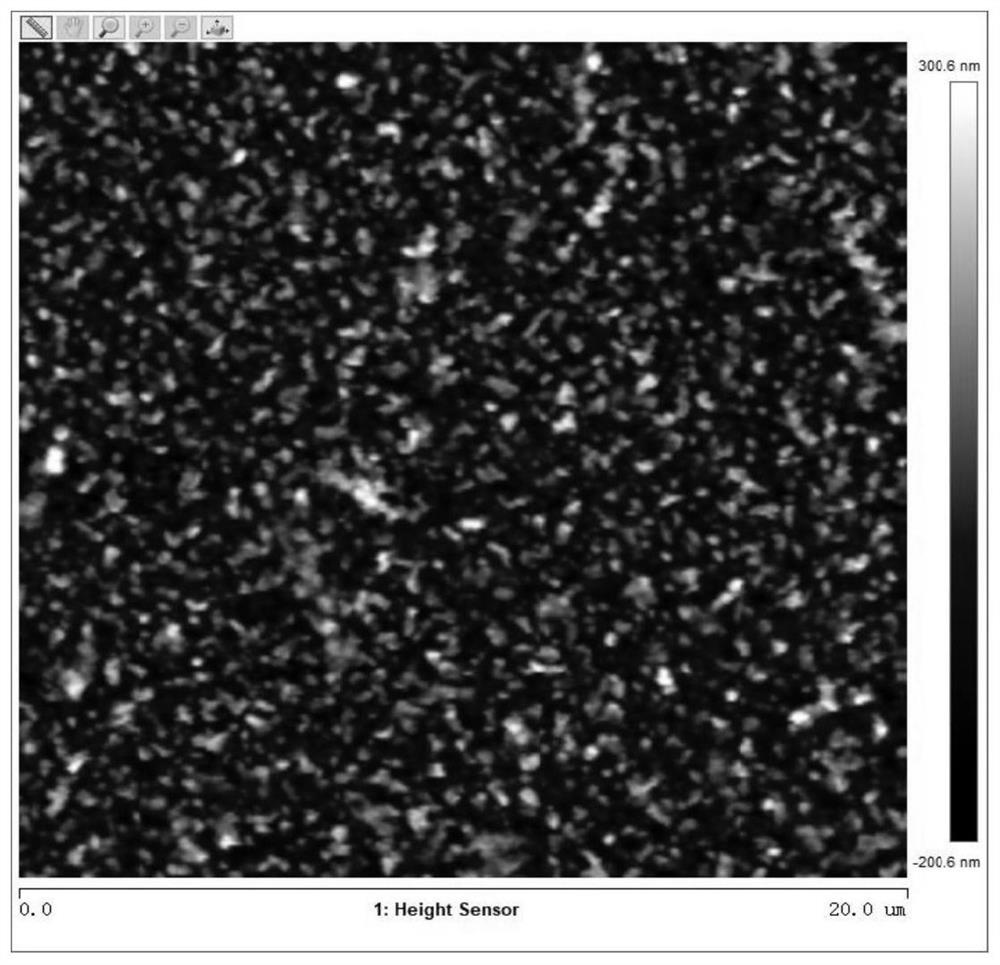

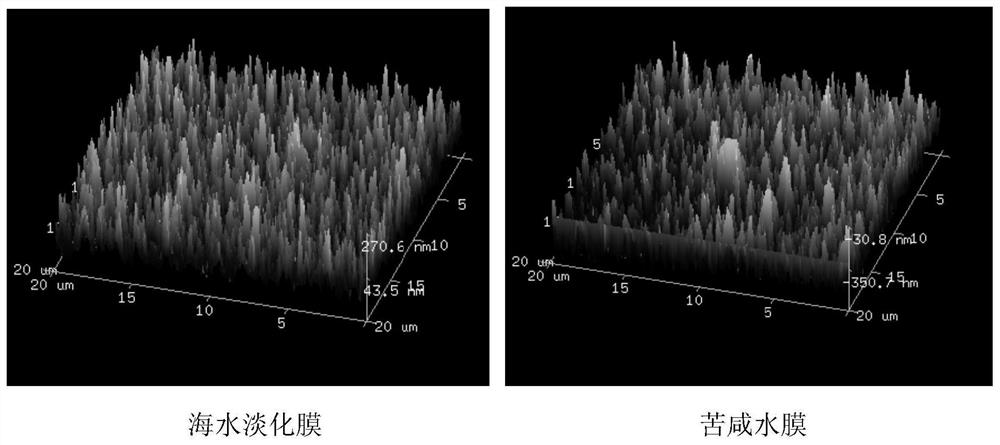

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com