Preparation methods of multi-rare-earth co-doped boride and nano heat insulation powder thereof and application of nano heat insulation powder

A nano-insulation and co-doping technology, applied in metal borides, boron/borides, nanotechnology, etc., can solve the problems of difficult large-scale industrial production, high cost, high energy consumption, and achieve effective thermal energy, good insulation Thermal effect, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

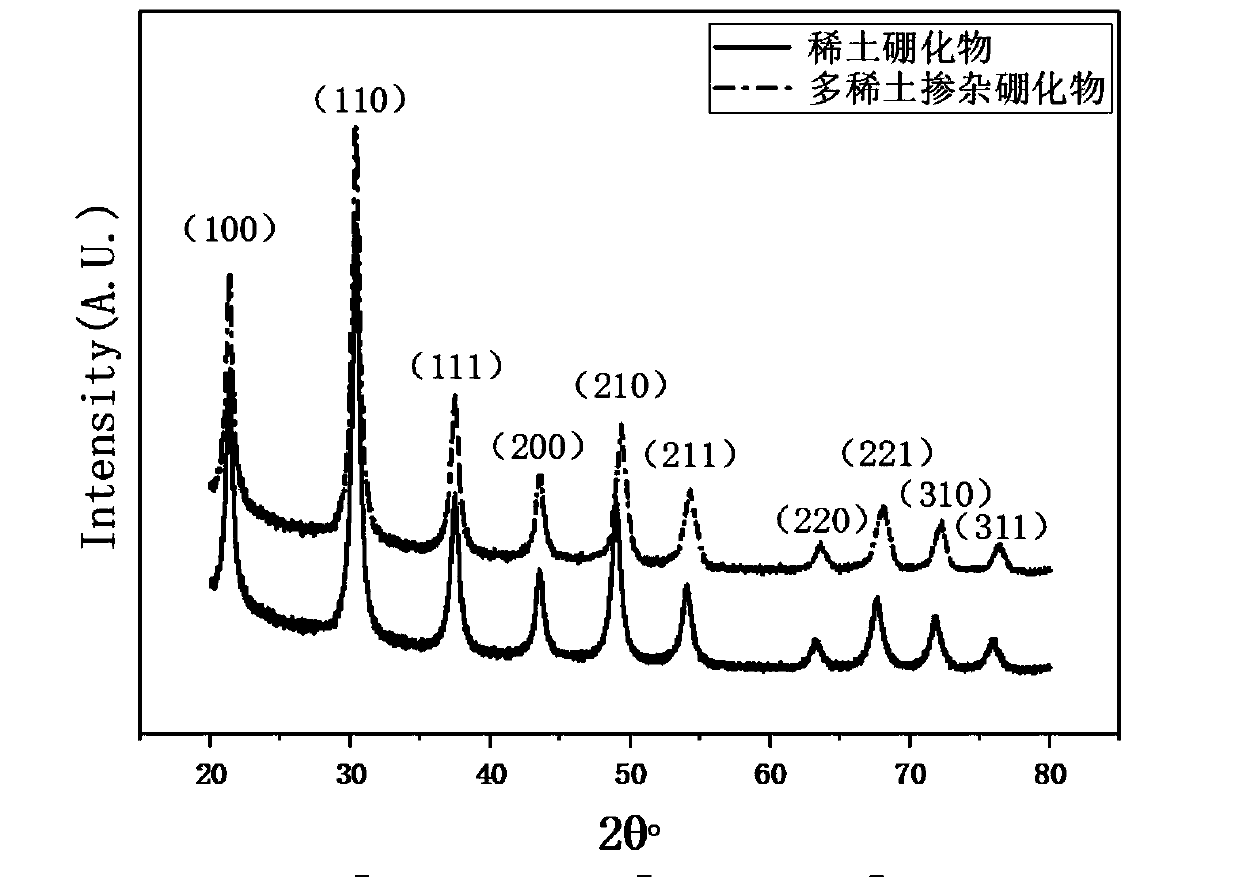

[0054] Multi-rare earth co-doped borides, the chemical formula is La 0.6 Eu 0.4 B 6 .

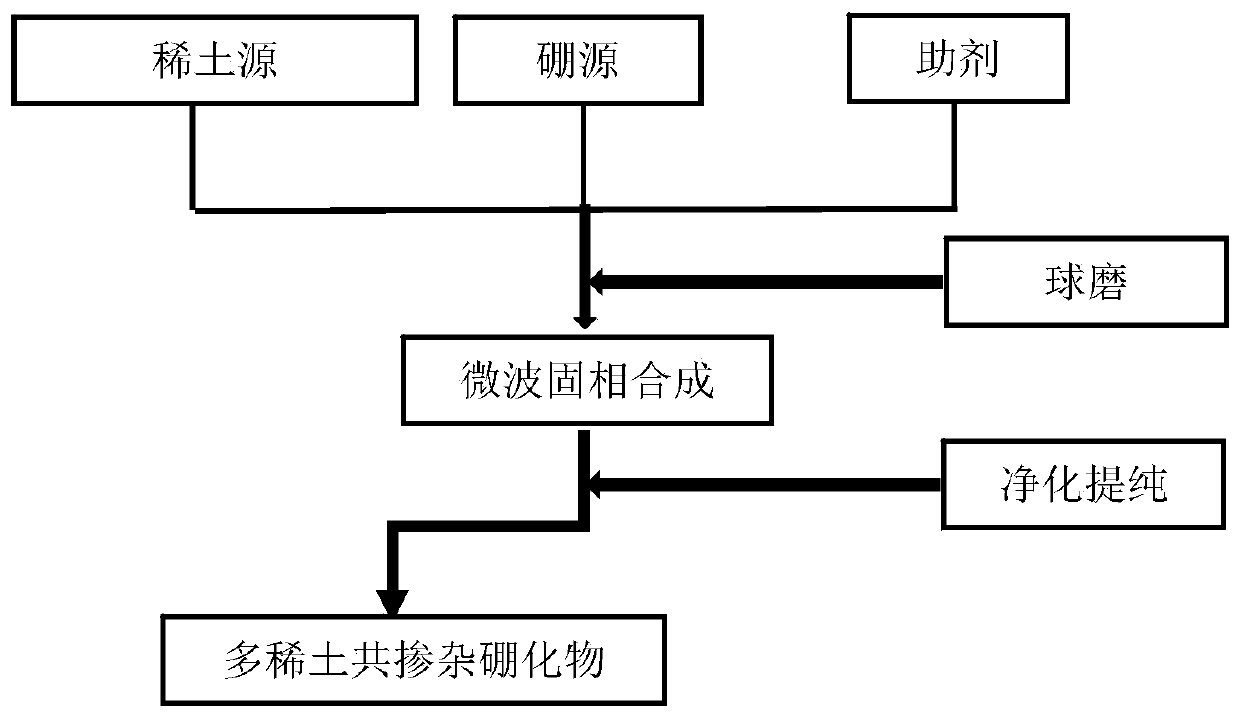

[0055] The preparation method of the above multi-rare earth co-doped boride is as follows: drying the rare earth source in an oven at 180° C. for 3 hours, and drying the boron source at 190° C. for 60 minutes. The dried rare earth source, boron source and additives were mixed and ball milled for 2 hours. The mixed raw materials were placed in a microwave experimental furnace, the temperature was raised to 700°C, kept for 6 hours, and cooled to room temperature with the furnace. The synthesized powder was repeatedly leached with dilute hydrochloric acid at 90°C, rinsed with distilled water and suction-filtered, and vacuum-dried to obtain the multi-rare earth co-doped boride powder. Among them, the content of rare earth source, boron source and additives is:

[0056] Rare earth source 301 parts by weight;

[0057] 324 parts by weight of boron source;

[0058] 195 parts by weight of auxi...

Embodiment 2

[0068] Multi-rare earth co-doped boride, its chemical formula is Gd 0.7 Ce 0.3 B 6 .

[0069] The preparation method of the above multi-rare earth co-doped boride is: drying the rare earth source mixture in an oven at 150° C. for 2 hours, and drying the boron source at 200° C. for 80 minutes. The dried rare earth source, boron source and additives were mixed and ball-milled for 2 hours, and the mixed raw materials were placed in a microwave experimental furnace, the temperature was raised to 600°C, kept for 8 hours, and cooled to room temperature with the furnace. The synthesized powder was repeatedly leached with dilute hydrochloric acid at 80°C, rinsed with distilled water and suction-filtered, and vacuum-dried to obtain the multi-rare earth co-doped boride powder. Among them, the contents of rare earth source, boron source and additives are as follows:

[0070] Rare earth oxide mixture 172 parts by weight;

[0071] 143 parts by weight of boron source;

[0072] 135 par...

Embodiment 3

[0082] Multi-rare earth co-doped borides, whose chemical formula is La 0.9 Gd 0.1 B 6 .

[0083] The preparation method of the above multi-rare earth co-doped boride is as follows: drying the rare earth source in an oven at 180° C. for 3 hours, and drying the boron source at 190° C. for 60 minutes. The dried rare earth source, boron source and additives were mixed and ball milled for 2 hours. The mixed raw materials were placed in a microwave experimental furnace, the temperature was raised to 800°C, kept for 8 hours, and cooled to room temperature with the furnace. The synthesized powder was repeatedly leached with dilute hydrochloric acid at 90°C, rinsed with distilled water and suction-filtered, and vacuum-dried to obtain the multi-rare earth co-doped boride powder. Among them, the content of rare earth source, boron source and additives is:

[0084] Rare earth source 458 parts by weight;

[0085] 485 parts by weight of boron source;

[0086] 234 parts by weight of auxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com