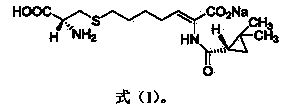

Preparation method of cilastatin sodium key intermediate

A technology of cilastatin sodium and intermediates, applied in the field of organic chemical synthesis, can solve the problems of difficult removal of impurities, easy generation of impurities, low conversion rate, etc., and achieve the effect of simple operation, improved yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

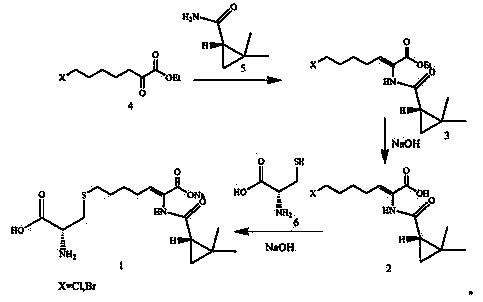

Method used

Image

Examples

Embodiment 1

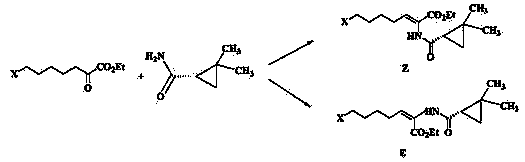

[0038] Step (1), in a reaction device equipped with a water separator, 50g (0.24mol) of 7-chloro-2-oxoheptanoic acid ethyl ester, (S)-2,2-dimethylcyclopropanecarboxamide 27.16g (0.24mol) and 0.9g of p-toluenesulfonic acid were added to 240mL of toluene, kept at reflux for 10h, and the reaction solution was cooled to room temperature after the reaction. The HPLC purity was 89.5%, and the E-configuration impurity was 10%.

[0039] In step (2), the reaction solution obtained in the previous step is placed in a 30°C incubator, and irradiated with ultraviolet light under a 20W ultraviolet lamp (the emission wavelength is 280nm, and the control light intensity is 450μW·cm -2 ), after irradiating for 60min, the reaction solution was washed twice with water, the organic layer was dried over anhydrous sodium sulfate, filtered, and toluene was evaporated to obtain (Z) 7-chloro-2((S)-2,2-dimethylcyclo Propanecarboxamido)-2-heptenoic acid ethyl ester, molar yield 99.5%, HPLC purity 99.8%,...

Embodiment 2

[0041] Step (1), in a reaction device equipped with a water separator, 50g (0.24mol) of 7-chloro-2-oxoheptanoic acid ethyl ester, (S)-2,2-dimethylcyclopropanecarboxamide 27.16g (0.24mol) and 0.9g of p-toluenesulfonic acid were added to 240mL of benzene, kept at reflux for 13h, and the reaction solution was cooled to room temperature after the reaction. The HPLC purity was 87.3%, and the E-configuration impurity was 12%.

[0042] In step (2), the reaction solution obtained in the previous step is placed in a 30°C incubator, and irradiated with ultraviolet light under a 20W ultraviolet lamp (the emission wavelength is 300nm, and the control light intensity is 450μW·cm -2 ), after irradiating for 60min, the reaction solution was washed twice with water, the organic layer was dried over anhydrous sodium sulfate, filtered, and benzene was evaporated to obtain (Z) 7-chloro-2((S)-2,2-dimethylcyclo Propane carboxamido)-2-heptenoic acid ethyl ester, molar yield 98.5%, HPLC purity 99.6%...

Embodiment 3

[0044] Step (1), in a reaction device equipped with a water separator, 50g (0.24mol) of 7-chloro-2-oxoheptanoic acid ethyl ester, (S)-2,2-dimethylcyclopropanecarboxamide 41.74g (0.36mol) and 0.9g of p-toluenesulfonic acid were added to 240mL of xylene, kept at reflux for 10h, and the reaction solution was cooled to room temperature after the reaction. The HPLC purity was 88.0%, and the E-configuration impurity was 9%.

[0045] In step (2), the reaction solution obtained in the previous step is placed in a 40°C incubator, and irradiated with ultraviolet light under a 20W ultraviolet lamp (the emission wavelength is 250nm, and the light intensity is controlled to be 450μW·cm -2 ), after irradiating for 60min, the reaction solution was washed twice with water, the organic layer was dried over anhydrous sodium sulfate, filtered, and xylene was evaporated to obtain (Z) 7-chloro-2((S)-2,2-dimethyl Cyclopropanecarboxamido)-2-heptenoic acid ethyl ester, molar yield 98.2%, HPLC purity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com