Ruthenium-iridium titanium-based metal oxide electrode material based on core-shell structure, preparation method and application thereof

A technology of noble metal oxides and core-shell structure, applied in the field of electrochemistry, can solve the problems of high cost, unfavorable large-scale application, low chlorine evolution potential, etc., achieve efficiency improvement, avoid selective dissolution and shedding, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of ruthenium iridium series titanium-based metal oxide electrode material based on core-shell structure of the present invention, its preparation method comprises the following steps:

[0034] 1. Pretreatment of the substrate

[0035] Sandblasting, degreasing and oxalic acid etching are performed on the surface of the substrate to obtain a uniform rough surface for later use, specifically:

[0036] 1.1) Sand blast the surface of the substrate first, then rinse with distilled water to remove residual sand and metal chips on the surface of the substrate;

[0037] 1.2) Put the rinsed substrate into acetone for degreasing;

[0038] 1.3) Finally, put the degreased substrate into the oxalic acid solution, perform surface etching in a boiling state, and then clean to obtain a uniform rough surface;

[0039] 1.4) Dry the substrate treated in step 1.3) and put it in absolute ethanol for later use.

[0040] 2. Preparation of electrode coating solution

[0041] The elec...

Embodiment 1

[0052] A method for preparing a ruthenium-iridium series titanium-based metal oxide electrode material based on a core-shell structure of the present invention comprises the following steps:

[0053] 1. Substrate pretreatment

[0054] 1.1) Use a TA2 industrial pure titanium plate with a plate shape of 140mm×110mm×3mm as the electrode substrate, first use corundum with a particle size of 120 μm to sandblast the surface of the substrate, and then rinse with distilled water to remove residual sand particles and metal chips on the surface of the substrate;

[0055] 1.2) Put the rinsed substrate into acetone for degreasing;

[0056] 1.3) Finally, put the degreased substrate into a 10% (mass fraction) oxalic acid solution, keep it in a boiling state for 2 hours for surface etching, and after taking it out, use ultrasonic cleaning in deionized water for 10 minutes to obtain a uniform rough surface;

[0057] 1.4) Dry the substrate treated in step 1.3) and put it in absolute ethanol f...

Embodiment 2

[0069] 1. Substrate pretreatment: the electrode substrate is made of reticular titanium material with a size of 100mm×100mm×3mm, and the same method as in Example 1 is used to perform sandblasting, degreasing and oxalic acid etching in sequence to obtain a pretreated titanium substrate for use .

[0070] 2. Preparation of electrode coating solution

[0071] 2.1) RuO 2 Preparation of nanoparticles: same as Example 1.

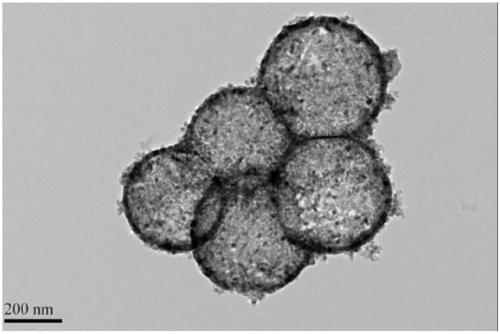

[0072] 2.2) IrO 2 @RuO 2 Preparation of particles: 0.18g RuO 2 Grind for 20min, put it into 20mL of absolute ethanol for ultrasonic dispersion for 2 hours, mix H 2 IrCl 6 ·6H 2 O was added to the above solution, and then the molar concentration of metal ions in the solution was adjusted to 0.3mol / L by adding n-butanol, the volume of the coating solution was 50mL, ammonia water was added dropwise to the solution under magnetic stirring, and the pH value was kept at 12. The mixture was stirred for 2 hours to obtain a coating liquid.

[0073] 3. Electrode p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com