Method for preparing ground phosphate pellets for yellow phosphorus production by utilizing medium-low-grade ground phosphate rock

A phosphate rock powder, low-grade technology, applied in the field of phosphorus chemical industry, can solve the problems of not meeting production requirements, waste of phosphate rock resources, waste of resources, etc., to improve resource utilization, reduce coke usage, and improve strength and grade Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

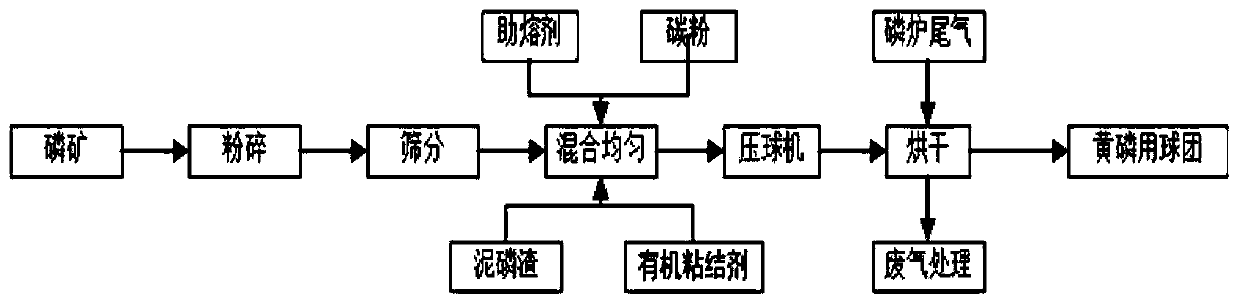

Image

Examples

Embodiment 1

[0036] A method for preparing phosphate rock pellets for yellow phosphorus production by using medium and low-grade phosphate rock powder, comprising the steps of:

[0037] 1) will P 2 o 5After the middle and low grade phosphate rock with a grade of 20.41% is dried and crushed, it is dry-screened with a vibrating sieve, and the material under the sieve of -1mm is collected as the raw material of phosphate rock powder;

[0038] 2) SiO 2 Carry out pickling treatment with the yellow phosphorus slag that CaO total content is 82wt%: add water and constantly stir 1 hour in the yellow phosphorus slag, filter, the gained solid matter is carried out pickling with dilute nitric acid (dilute nitric acid concentration is 27%, solid-liquid The ratio is 1:3g:ml) to further remove the acid-soluble matter; the acid-insoluble matter is dried. Obtain modified yellow phosphorus slag;

[0039] 3) The industrial pulp waste liquid is processed through a 200-mesh sieve to remove large materials,...

Embodiment 2

[0044] A method for preparing phosphate rock pellets for yellow phosphorus production by using medium and low-grade phosphate rock powder, comprising the steps of:

[0045] 1) will P 2 o 5 After the medium and low grade phosphate rock with a grade of 23.17% is dried and crushed, it is dry-screened with a vibrating sieve, and the material under the sieve of -1mm is collected as the raw material of phosphate rock powder;

[0046] 2) Take by weighing 100 parts by weight of phosphate rock raw material, 0.3 parts by weight of modified pulp waste liquid obtained in Example 1, 7.12 parts by weight of modified yellow phosphorus slag obtained in Example 1, 15 parts by weight of carbon powder and 15 parts by weight of P 2 o 5 The mud phosphorus slag with a grade of 17.33% is mixed evenly, and water is added to make the water content of the material after mixing to be 8%, and then the pellets are pressed, and the green pellets for yellow phosphorus are obtained after drying (120°C, 1h)...

Embodiment 3

[0050] A method for preparing phosphate rock pellets for yellow phosphorus production by using medium and low-grade phosphate rock powder, comprising the steps of:

[0051] 1) will P 2 o 5 After the medium and low grade phosphate rock with a grade of 22.62% is dried and crushed, it is dry-screened with a vibrating sieve, and the material under the sieve of -1mm is collected as the raw material of phosphate rock powder;

[0052] 2) Take by weighing 100 parts by weight of phosphate rock raw material, 0.3 parts by weight of modified pulp waste liquid obtained in Example 1, 7.46 parts by weight of composite flux (6.48 parts by weight of modified yellow phosphorus slag gained in Example 1 and 0.98 parts by weight of potassium feldspar ), 15 parts by weight carbon powder and 10 parts by weight P 2 o 5 The mud phosphorus slag with a grade of 17.33% is mixed evenly, and water is added to make the water content of the material after mixing to be 8%, and then the pellets are pressed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com