Fabric detergent, preparation method and application thereof

A detergent and fabric technology, applied in detergent compositions, detergent compounding agents, surface-active detergent compositions, etc., can solve the problem of large waste liquid, low dissolving ability of pigment and medicine stains, increased fabric washing time cost, labor Cost and economic costs and other issues, to achieve good bleaching and decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

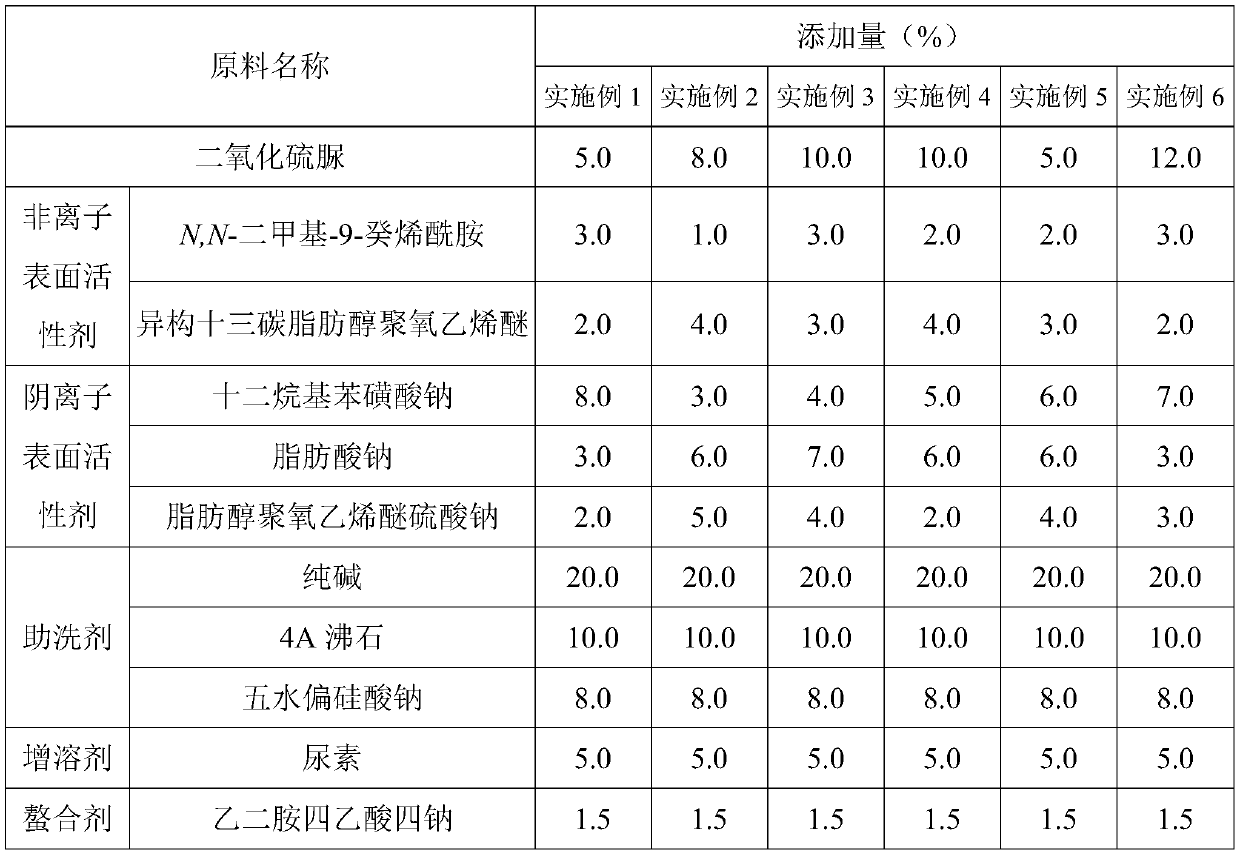

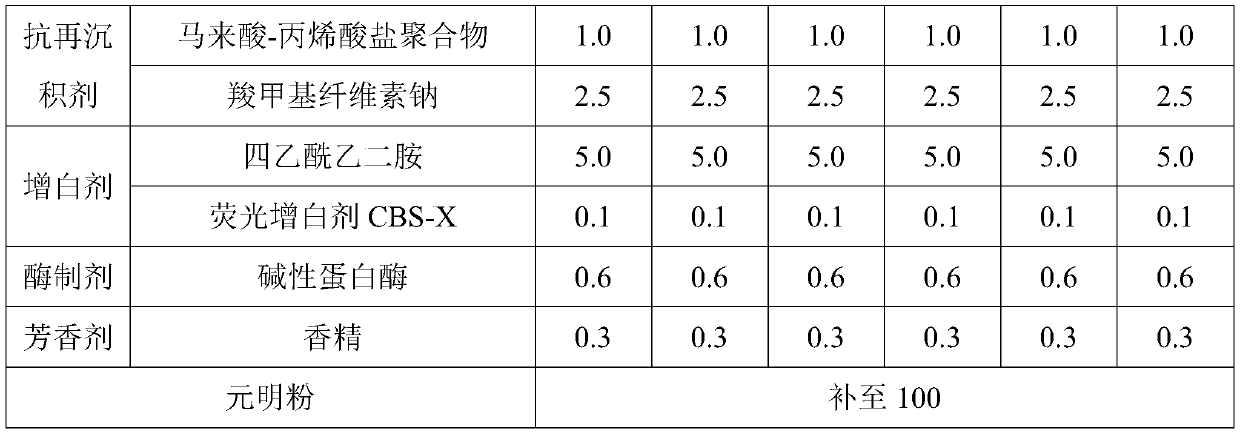

[0058] Concrete components and component contents (by weight percentage) of the fabric detergent provided by Embodiment 1~6 are as shown in Table 1:

[0059] Table 1

[0060]

[0061]

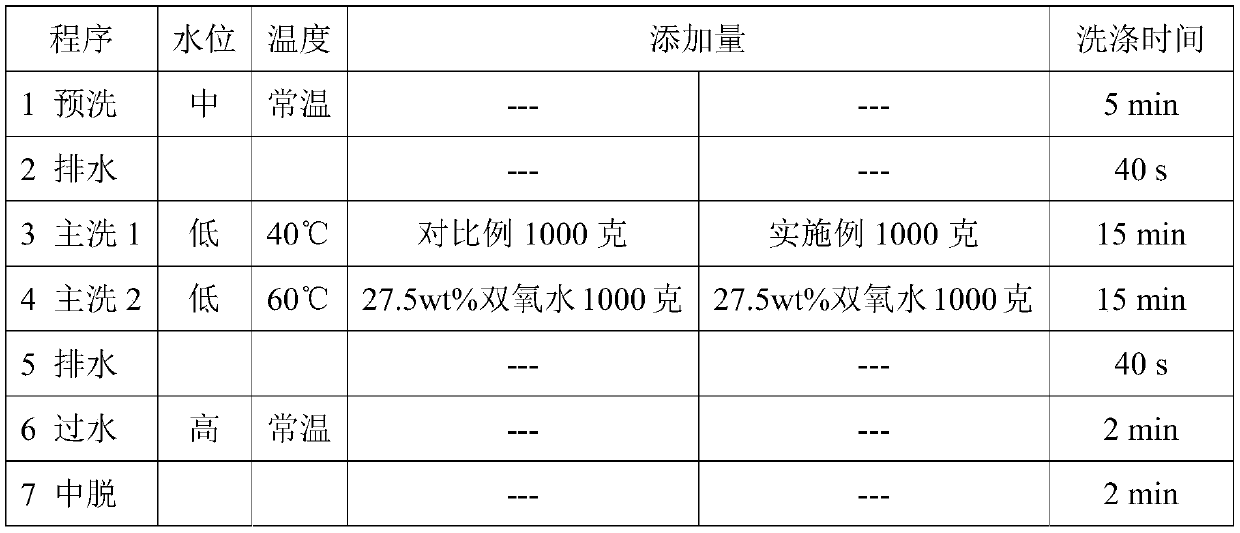

[0062] The preparation method of the fabric detergent that embodiment 1~6 provides comprises the following steps:

[0063] (1) Turn on the industrial dehumidifier and dust removal fan to reduce the air humidity in the production workshop to 40%.

[0064] (2) Soda ash, 4A zeolite, sodium metasilicate pentahydrate, urea, tetrasodium edetate, maleic acid-acrylate polymer, sodium carboxymethylcellulose, tetraacetyl Add ethylenediamine and fluorescent whitening agent CBS-X into the conical mixer, turn on the conical mixer and stir for 5 minutes; Add sodium into the conical mixer and continue stirring for 5 minutes; then add N,N-dimethyl-9-decenamide and isomeric tridecyl fatty alcohol polyoxyethylene ether through the feeder, and continue stirring for 2 minutes; Then add thiourea dioxide an...

Embodiment 7

[0067] This embodiment provides a kind of fabric detergent, and the only difference from Embodiment 1 is that the addition amount of N,N-dimethyl-9-decenamide in the nonionic surfactant is 0.5%, and the iso The addition amount of tridecyl fatty alcohol polyoxyethylene ether is 4.5%, and other component content and preparation method are with embodiment 1.

Embodiment 8

[0069] This embodiment provides a kind of fabric detergent, and the only difference from Embodiment 1 is that N,N-dimethyl-9-decenamide is not added to the nonionic surfactant, and the isomeric tridecyl The content of fatty alcohol polyoxyethylene ether is increased to 5.0%, and the content and preparation method of other components are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com