Steel piston and preparation method thereof

A piston and steel technology, applied in the field of steel piston and its preparation, can solve the problems of uneven temperature distribution, serious heating, poor heat dissipation conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

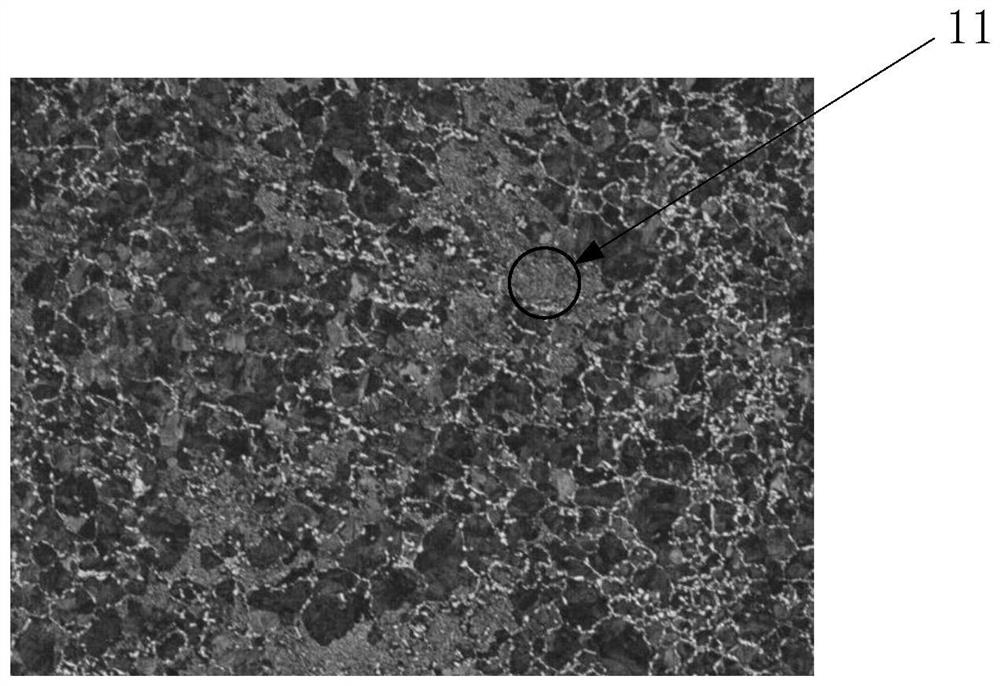

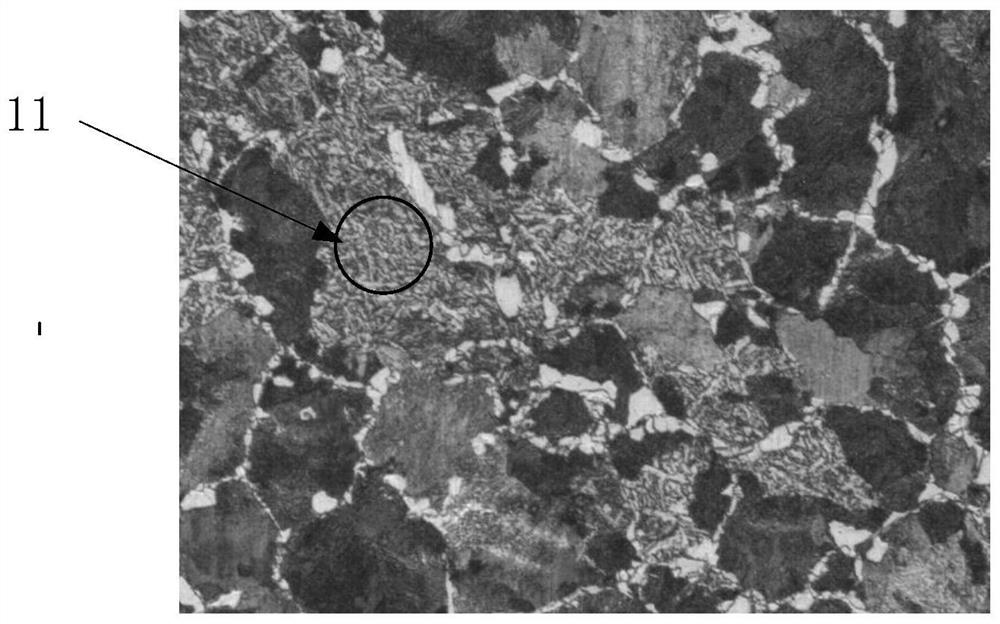

Image

Examples

preparation example Construction

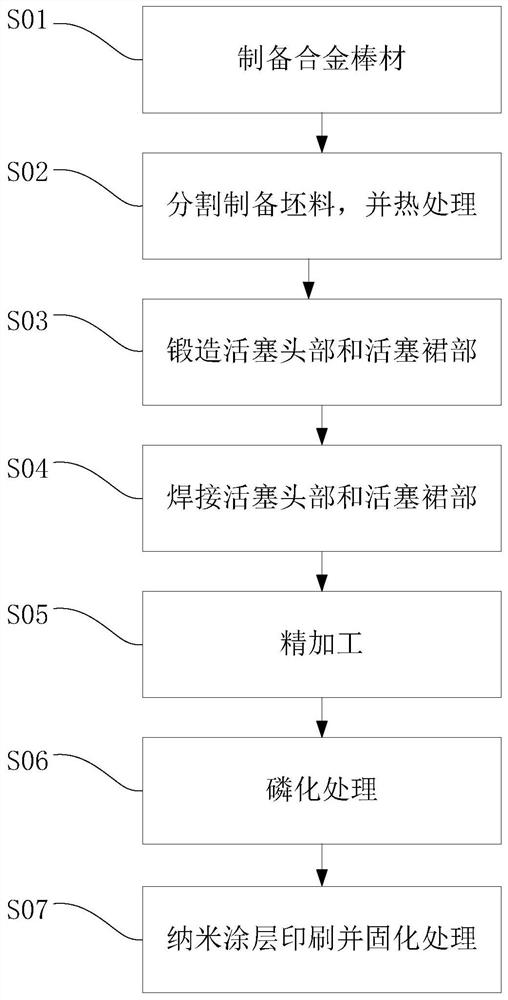

[0048] Based on the composition and percentage of the above-mentioned steel piston, the present invention also provides a preparation method of the steel piston, comprising the steps of:

[0049] S01: Preparation of alloy rods

[0050] After mixing carbon source, silicon source, phosphorus source, sulfur source, manganese source, copper source, nitrogen source, vanadium source, titanium source and iron source, the alloy bar is obtained through smelting, deoxidation and hot rolling.

[0051] In this case, there are no special restrictions on the types and sources of carbon sources, silicon sources, phosphorus sources, sulfur sources, manganese sources, copper sources, and iron sources. The raw materials for low-alloy steel smelting well known to those skilled in the art can be used. Elemental material of composition. The amount ratio of carbon source, silicon source, phosphorus source, sulfur source, manganese source, copper source, nitrogen source, vanadium source, titanium s...

Embodiment 1

[0082] Mix carbon, silicon, phosphorus, sulfur, manganese, copper, vanadium, titanium, nitrogen and iron, and accurately weigh each raw material for smelting. The smelting temperature is 1600-1620°C. After smelting, the obtained alloy liquid is blown with oxygen. Make slagging to reduce phosphorus, sulfur and other elements to the required composition range, and carry out slagging treatment, continuous casting and rolling, rolling temperature 1150 ~ 1250 ℃, air cooling to room temperature after rolling.

[0083] The alloy bar is divided into blanks of predetermined specifications, which are forged into piston heads and piston skirts. During this process, the heating temperature of the forging billet is 1200-1300°C. The final forging temperature in the forging process is 1100-1200°C, and the preheating temperature of the mold during the forging process is 200-300°C.

[0084] In the cooling process after forging of the present invention, the method for controlling cooling is: ...

Embodiment 2

[0102] Mix carbon, silicon, phosphorus, sulfur, manganese, copper, lead and iron, and accurately weigh each raw material for smelting. The smelting temperature is 1580-1600°C. Phosphorus, sulfur and other elements are reduced to the required composition range, and the slag removal treatment is carried out, and continuous casting and rolling are carried out. The rolling temperature is 1150-1250 ° C. After rolling, it is air-cooled to room temperature.

[0103] In this embodiment, the blanks of the piston head and the piston skirt are forged. The heating temperature of forging blank is 1200~1300℃. The final forging temperature in the forging process is 1100-1200°C. The preheating temperature of the mold during the forging process is 200-300°C.

[0104] In the cooling process after embodiment forging, the method for controlling cooling is:

[0105] Rapid cooling of the forged blank to 600-650°C by means of spray cooling, and then air cooling to room temperature to obtain steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com