Method for growing scintillation crystal seed crystal in multiple crucibles

A scintillator and multi-crucible technology is applied in the field of preparation of scintillation crystal material seed crystals, which can solve the problems of complex scintillator seed crystal process and waste of raw materials, and achieves the effects of excellent seed crystal quality, reduced production cost, and simplified orientation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

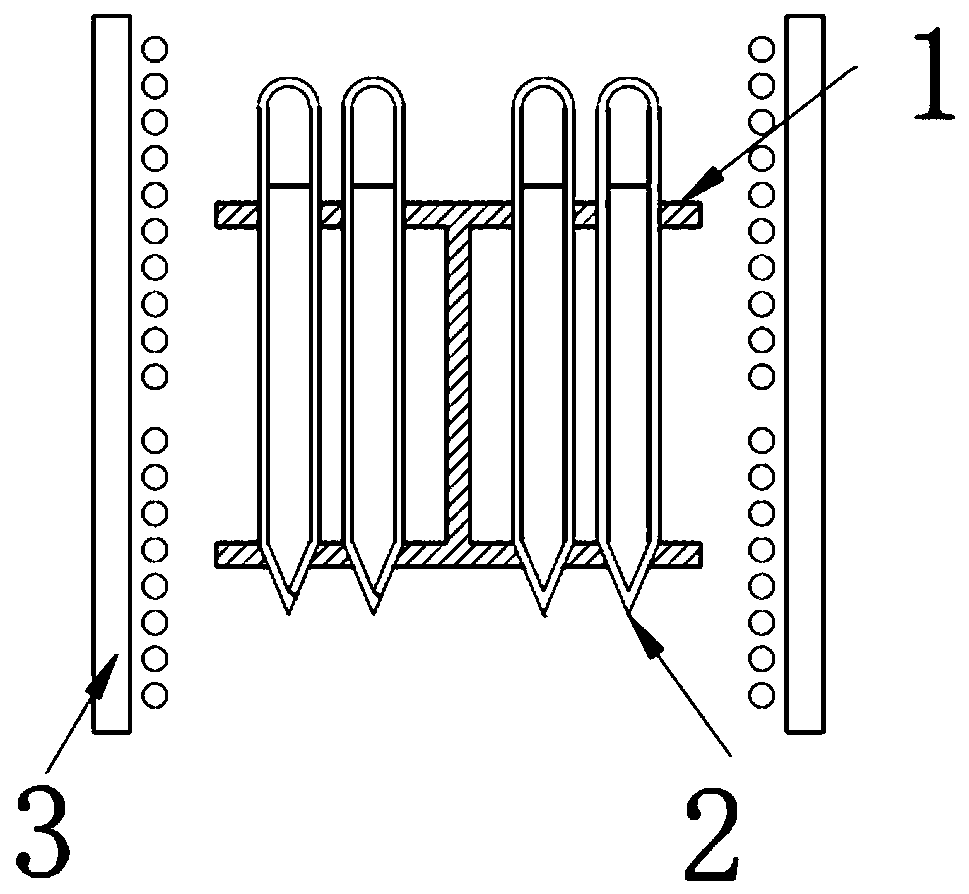

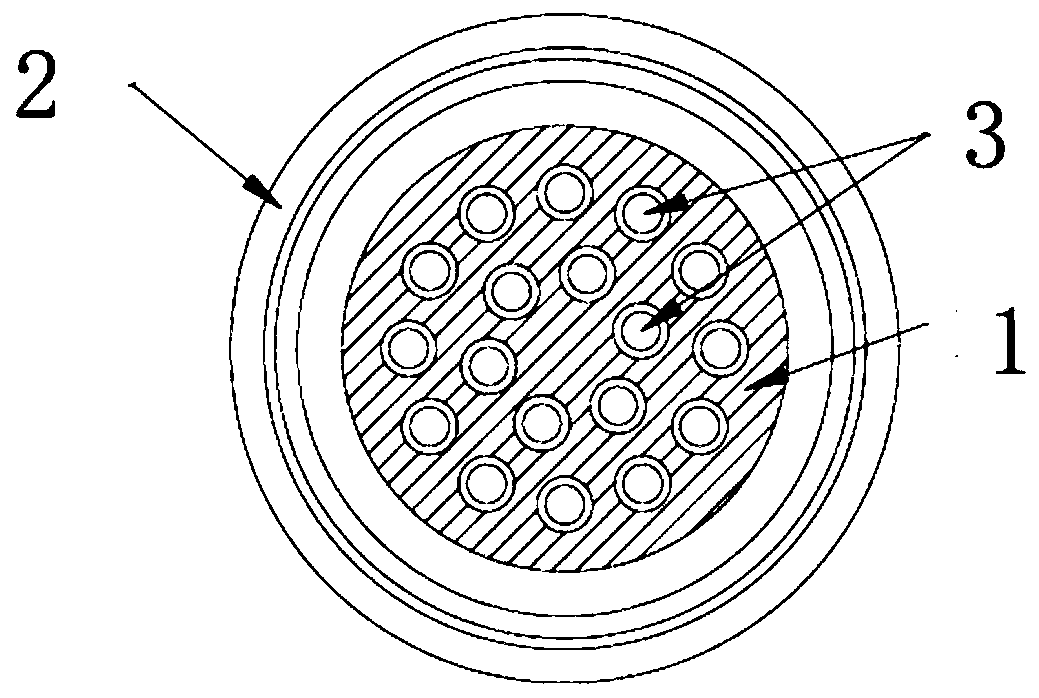

[0030] In the first step, under the argon atmosphere in the glove box, put the 4N pure NaI raw material into a clean and dry special quartz crucible. The inner diameter of the crucible is 5mm, and the quantity is 15 pieces. Vacuum the quartz crucible to a vacuum of 7×10 -5 Seal the tube at Pa.

[0031] The second step is to place the above-mentioned quartz crucibles together in a high-temperature mixing furnace, preferably rapidly raise the temperature to 700°C at a rate of 70°C per hour, then perform rocking and oscillating mixing for 12 hours, turn off the furnace to cool down, and the mixing is completed.

[0032]The third step is to transfer the above-mentioned quartz crucible to the support together, and then place the support in the Bridgman crystal growth furnace. The zone temperature was 560°C and the heating time was 9 hours. After reaching the target temperature, superheat at 30°C above the melting point of sodium iodide for 24 hours. Preferably, the temperature ...

Embodiment 2

[0036] In the first step, under the argon atmosphere in the glove box, put the raw material of lanthanum bromide with a purity of 5N into a clean and dry special quartz crucible. The inner diameter of the crucible is 7mm, and the quantity is 9 pieces. Vacuum the quartz crucible with a vacuum degree of 8×10 -5 Seal the tube at Pa.

[0037] The second step is to place the above-mentioned quartz crucibles together in a high-temperature mixing furnace, preferably rapidly raising the temperature to 810°C at a rate of 100°C per hour, then rocking and oscillating the mixing for 24 hours, turning off the furnace to cool down, and the mixing is completed.

[0038] The third step is to transfer the above-mentioned quartz crucible to the support together, and then place the support in the Bridgman crystal growth furnace. The zone temperature was 700°C and the heating time was 10 hours. After reaching the target temperature, superheat at 50°C above the melting point of lanthanum bromid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com