High-performance environment-friendly lead-based perovskite solar cell and preparation method thereof

An environmentally friendly, solar cell technology, applied in the field of solar cells, can solve the problems of lead leakage, human health hazards, etc., achieve the effects of passivating grain boundaries, reducing human harm, and optimizing crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Provide a transparent conductive substrate of fluorine-doped tin oxide (FTO), and perform standardized cleaning;

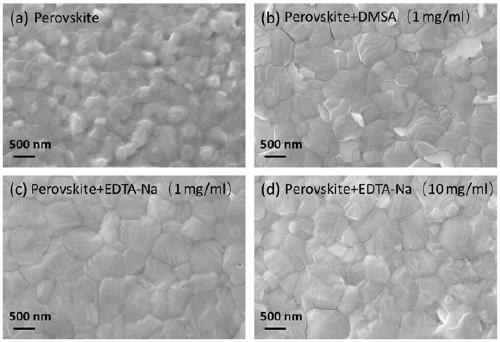

[0028] (2) Dissolve 599 mg of lead iodide in 1 mL of a mixed solution of dimethyl sulfoxide and dimethylformamide (volume ratio 5:95), and simultaneously add 70 mg of FAI, 7 mg of MABr, and 7 mg of MACl and 1 mg of disodium edetate dissolved in 1 mL of isopropanol;

[0029] (3) Treat FTO with ozone for 30 min, then add tin oxide solution dropwise, rotate at 4000 rpm for 40 s, and then anneal at 180 °C for 30 min to obtain a cured electron transport layer;

[0030] (4) The lead-based perovskite film layer was prepared by a two-step method. The lead iodide solution was rotated at 1500 rpm for 30 s, and the annealing temperature was 70 °C for 1 min. Then add the isopropanol solution of the ammonium salt of disodium edetate, rotate at 1700 rpm for 30 s, and anneal in air at 150°C for 10 min to obtain a lead-based perovskite film layer;

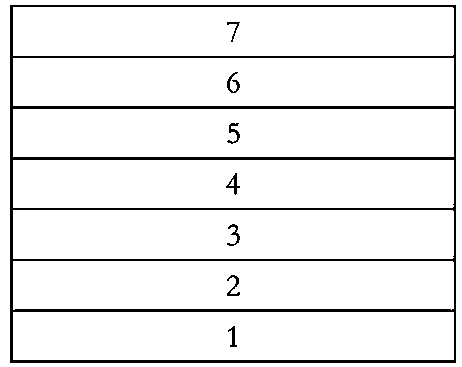

[0031] (5) Hole t...

Embodiment 2

[0035] (1) Provide a transparent conductive substrate of fluorine-doped tin oxide (FTO), and perform standardized cleaning;

[0036] (2) Dissolve 599 mg of lead iodide in 1 mL of a mixed solution of dimethyl sulfoxide and dimethylformamide (volume ratio 5:95), and simultaneously add 70 mg of FAI, 7 mg of MABr, and 7 mg of MACl and 1 mg of 2,3-dimercaptosuccinic acid dissolved in 1 mL of isopropanol;

[0037] (3) Treat the FTO with ozone for 30 min, then add tin oxide solution dropwise, rotate at 4000 rpm for 40 s, and then anneal at 180 °C for 30 min to obtain a cured electron transport layer;

[0038] (4) The lead-based perovskite film layer was prepared by a two-step method. The lead iodide solution was rotated at 1500 rpm for 30 s, and the annealing temperature was 70 °C for 1 min. After that, the isopropanol solution of ammonium salt of 2,3-dimercaptosuccinic acid was added and rotated at 1700 rpm for 30 s, the annealing temperature in air was 150 °C, and the time was 10 ...

Embodiment 3

[0043] (1) Provide a transparent conductive substrate of fluorine-doped tin oxide (FTO), and perform standardized cleaning;

[0044](2) Dissolve 599 mg of lead iodide in 1 mL of a mixed solution of dimethyl sulfoxide and dimethylformamide (volume ratio 5:95), and simultaneously add 70 mg of FAI, 7 mg of MABr, 7 mg of MACl and 10 mg of disodium edetate dissolved in 1 mL of isopropanol;

[0045] (3) Treat the FTO with ozone for 30 min, then add tin oxide solution dropwise, rotate at 4000 rpm for 40 s, and then anneal at 180 °C for 30 min to obtain a cured electron transport layer;

[0046] (4) The lead-based perovskite film layer was prepared by a two-step method. The lead iodide solution was rotated at 1500 rpm for 30 s, and the annealing temperature was 70 °C for 1 min. Then add the isopropanol solution of disodium edetate ammonium salt and rotate at 1700 rpm for 30 s, anneal in air at 150°C for 10 min to obtain a lead-based perovskite film layer;

[0047] (5) Hole transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com