M-xylylenediamine hydrogenation catalyst, preparation method and application thereof

A m-xylylenediamine and catalyst technology, which is applied in the field of hydrogenation catalyst and its preparation, can solve the problems of environmental pollution, large amount of catalyst, and affecting production efficiency, etc., to improve selectivity and stability, stabilize activity and selectivity , Improve the effect of adsorption and activation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

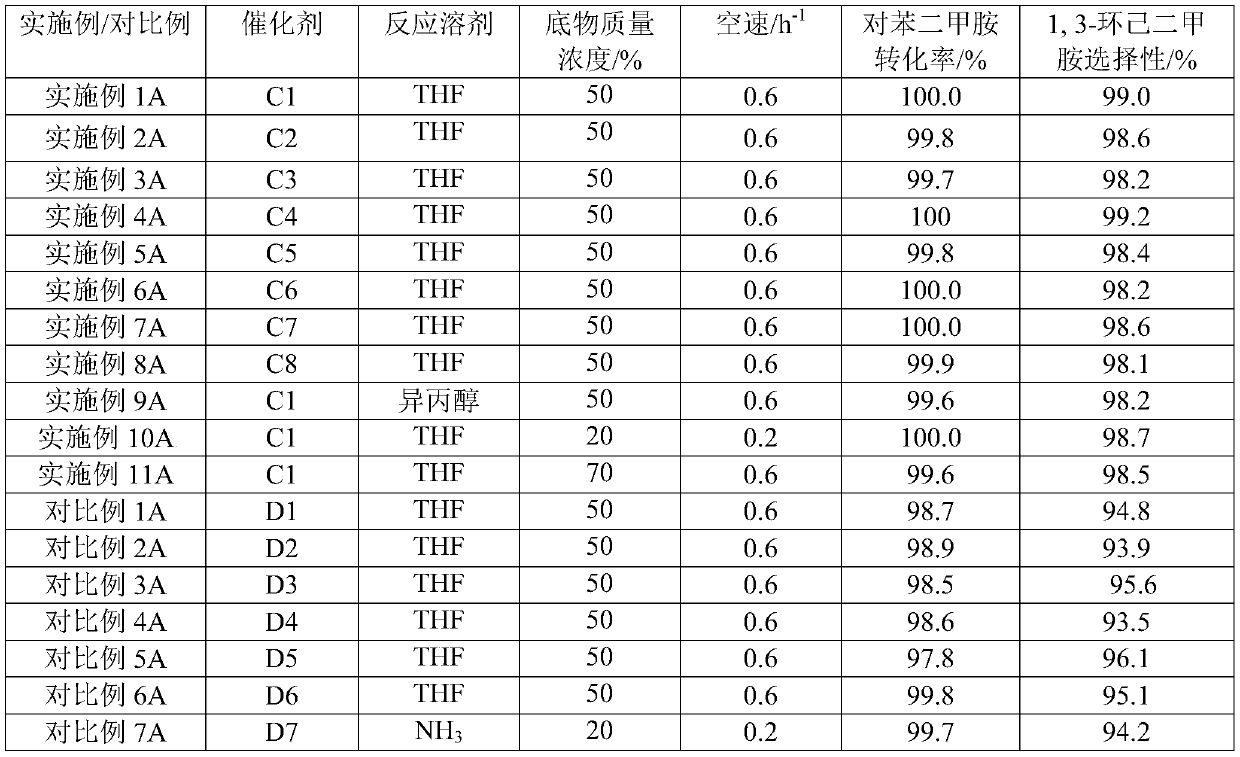

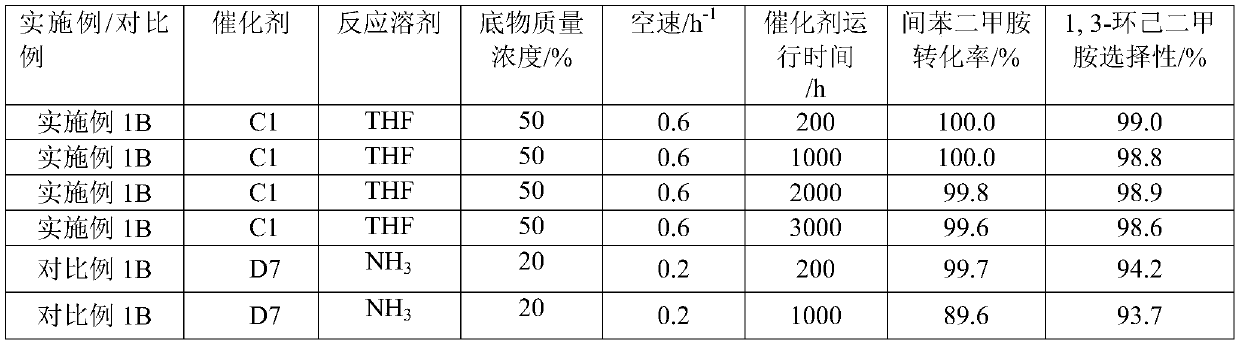

Examples

Embodiment 1

[0055] (1) Weigh 20g Ca(NO 3 ) 2 .4H 2 O, add 200g water to dissolve, then add 150g SBA-15 molecular sieve, heat up to 50°C, add 5g NaOH, stir for 5h, filter, wash with distilled water until the pH is 7, dry the filter cake at 100°C for 10h, and then dry it at 400°C Roast for 6h, cool down to room temperature, and set aside;

[0056] (2) Weigh the modified molecular sieve obtained in 100g step (1), 0.005g metal Eu, 0.05g Yb, join in 1L autoclave, fill 1MPa nitrogen replacement, repeat 3 times, add 200g liquid ammonia again, water bath is heated to Stir at 40°C for 5 hours, then cool down to room temperature, exhaust the nitrogen and liquid ammonia in the kettle, open the kettle, wash out the catalyst in the kettle with ethanol, filter out the carrier, wash with ethanol and distilled water respectively, and dry at 110°C; Place the dried carrier in a muffle furnace, bake it at 500°C for 5h under a nitrogen atmosphere, and then cool it down to room temperature for use;

[005...

Embodiment 2

[0060] Catalyst sample C2 was prepared by the same method steps as in Example 1, except that PEG-600 was not added in step (3), but 40 g of CTAB was added.

Embodiment 3

[0062] Catalyst sample C3 is prepared by the same method steps as in Example 1, and the difference is: in step (1), use 15gMg(NO 3 ) 2 .6H 2 O instead of 20g Ca(NO 3 ) 2 .4H 2 O, replace SBA-15 with 100gβ molecular sieve, RuCl in step (3) 3 .3H 2 O mass is 5.10g, H[AuCl 4 ] quality is 0.11g, the NaBH that is 1mol / L is added dropwise with the rate of 50mL / min 4 Aqueous solution 200mL, do not pass methylamine in the step (4), but pass into 4000g ethylenediamine with the speed of 1000g / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com