Quantum dot composite material ink, and preparation method and application thereof

A composite material and quantum dot technology, which is applied in the field of quantum dot composite ink and preparation, can solve problems such as the influence of quantum dot ink curing, failure to achieve inkjet effect, easy to block nozzles, etc., achieve excellent anti-flocculation effect, and avoid coffee rings effect, enhance solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

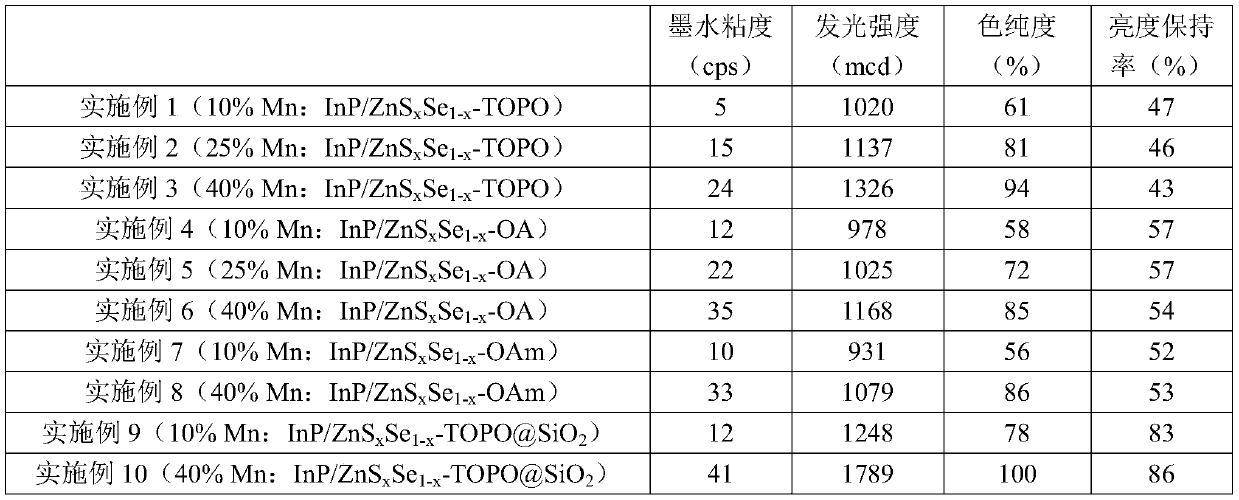

Embodiment 1

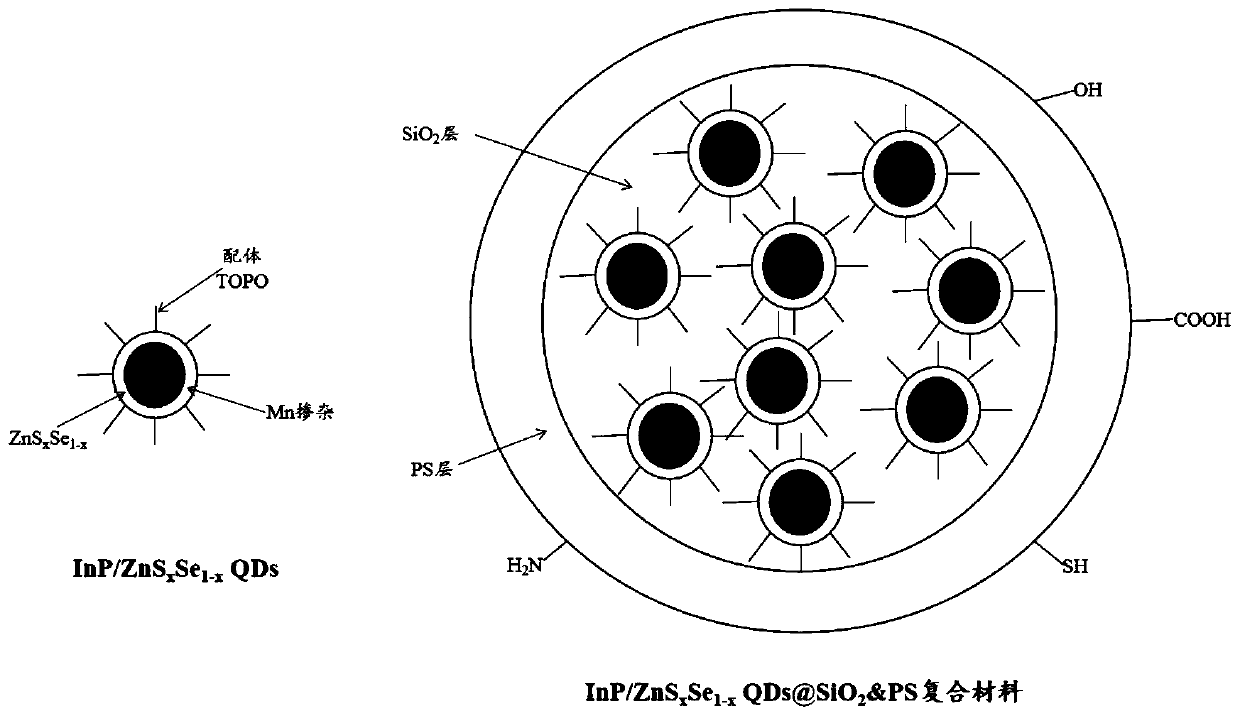

[0041] S1, 37.5wt% novolac epoxy acrylate, 37.5wt% isobornyl methacrylate and 5wt% 2,4,6-trimethylbenzoyl-diphenylphosphine oxide were mixed at room temperature, Use a rotor agitator to stir and disperse until the solids are completely dissolved to obtain a colorless UV ink;

[0042] S2, 10wt% red Mn: InP / ZnS x Se 1-x - TOPO (manganese doped, shell ZnSe and ZnS, ligand is TOPO) quantum dot composite powder grinding, after 300 mesh sieve, after weighing, take an appropriate amount and add it to the above UV ink, then add 10wt% propylene glycol Methyl ether acetate, pre-mixed and shaken with a blender;

[0043] S3. Put the above-mentioned pre-mixed composite material ink into an ultrasonic cleaner for ultrasonication, and add UV ink drop by drop to the preset ink volume. The whole process lasts for 20-40 minutes. The final quantum dot composite material ink is clear and transparent without precipitation.

Embodiment 2

[0045] The preparation method is basically the same as that of Example 1, the difference is that

[0046] Novolak epoxy acrylate 30wt%;

[0047] Isobornyl methacrylate 30wt%;

[0048] 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 5wt%;

[0049] Red Mn: InP / ZnS x Se 1-x -TOPO (manganese doped, shell ZnSe and ZnS, ligand is TOPO) quantum dot composite material 25wt%;

[0050] Propylene glycol methyl ether acetate 10wt%.

Embodiment 3

[0052] The preparation method is basically the same as that of Example 1, the difference is that

[0053] Novolak epoxy acrylate 22.5wt%;

[0054] Isobornyl methacrylate 22.5wt%;

[0055] 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 5wt%;

[0056] Red Mn: InP / ZnS x Se 1-x -TOPO (manganese doped, shell ZnSe and ZnS, ligand is TOPO) quantum dot composite material 40wt%;

[0057] Propylene glycol methyl ether acetate 10wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com