Manganese dioxide loaded nitrogen-sulfur double-doped graphene catalyst for oxygen reduction reaction, preparation method of manganese dioxide loaded nitrogen-sulfur double-doped graphene catalyst and application of manganese dioxide loaded nitrogen-sulfur double-doped graphene catalyst

A technology of manganese dioxide and graphene, applied in the direction of fuel cell half-cells and primary battery half-cells, fuel cell half-cells and secondary battery-type half-cells, electrical components, etc., can solve oxygen Reduction reaction kinetics is slow and other problems, to achieve excellent catalytic activity, reduce manufacturing costs, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

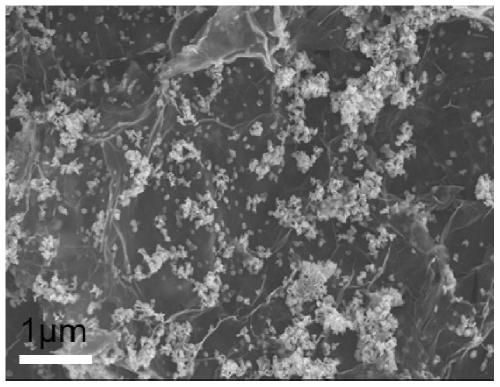

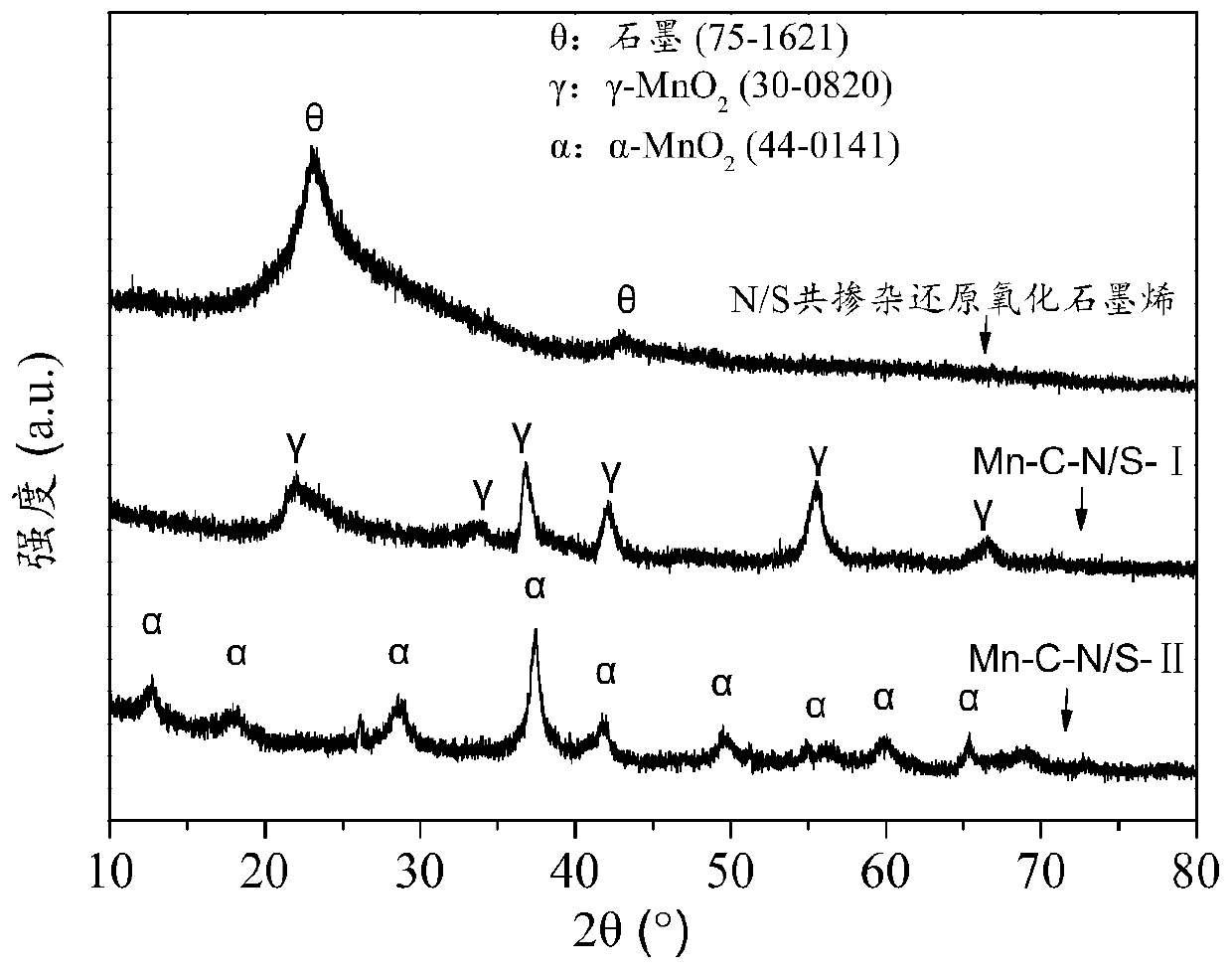

[0036] The steps of preparing manganese dioxide-loaded nitrogen-sulfur double-doped graphene catalyst are as follows:

[0037] The graphite oxide stock solution was prepared by using the existing Hummers modification method in the prior art, and the graphene oxide with a mass concentration of 4.4 mg / mL was obtained by centrifugation and stripping with ultrapure water. Measure 48 mL of graphene oxide, centrifuge for 10 min in a centrifuge, pour off the upper layer of the centrifuged liquid, pour the lower graphene oxide into a measuring cylinder, add 50 mL of organic solvent N-methylpyrrolidone, then weigh 2 g of thiourea, and Mix graphene oxide and organic solvent evenly, put it into a hydrothermal reaction kettle, and reduce it with nitrogen in a vacuum drying oven at 80°C for 24 hours. After the reduction, take the graphene out of the reaction kettle, cool and wash it, and put the The co-doped reduced graphene oxide suspension, manganese chloride tetrahydrate and potassium p...

Embodiment 2

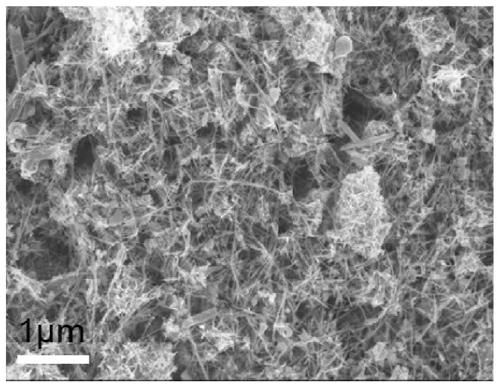

[0043] The steps of preparing manganese dioxide-loaded nitrogen-sulfur double-doped graphene catalyst are as follows:

[0044] The graphite oxide precursor was prepared by the existing Hummers modification method in the prior art, and the graphene oxide with a mass concentration of 4.4 mg / mL was obtained by centrifugation and stripping with ultrapure water. Measure 48mL of graphene oxide, centrifuge for 10min in a centrifuge, pour off the upper clear water of the centrifugation solution, pour the lower graphene oxide into a measuring cylinder, add 50mL of organic solvent N-methylpyrrolidone, weigh 2g of thiourea, and Mix graphene and organic solvent evenly, put it into a hydrothermal reaction kettle, and reduce it with nitrogen in a vacuum drying oven at 80 °C for 24 hours. The doped reduced graphene oxide suspension, manganese chloride tetrahydrate and potassium permanganate were mixed and stirred according to the mass ratio of 1:10:20, and the stirring was continued for 30 m...

Embodiment 3

[0050] The steps of preparing manganese dioxide-loaded nitrogen-sulfur double-doped graphene catalyst are as follows:

[0051] The graphite oxide precursor was prepared by the existing Hummers modification method in the prior art, and the graphene oxide with a mass concentration of 4.4 mg / mL was obtained by centrifugation and stripping with ultrapure water. Measure 60 mL of graphene oxide, centrifuge for 30 minutes in a centrifuge, pour off the upper layer of water, pour the lower graphene oxide into a graduated cylinder, add 30 mL of organic solvent N,N-dimethylformamide, and then measure 5 mL of dopamine and cysteine 5mL, mixed evenly with graphene oxide and organic solvent, put it into a hydrothermal reaction kettle, and reduced it with nitrogen in a vacuum drying oven at 100°C for 12h. After the reduction, the graphene was taken out of the reaction kettle and cooled And after washing, the N / S co-doped reduced graphene oxide suspension, manganese chloride tetrahydrate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com