Sulfonic acid-based anionic gemini surfactant and preparation method thereof

A Gemini surface, anion technology, applied in chemical instruments and methods, dissolution, drilling composition, etc., can solve the problems of easy adsorption by clay surface, low temperature and salt resistance, poor rock wetting and reversal effect, etc. , to achieve excellent surface activity, good wettability, and meet the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The application also provides a preparation method of a sulfonic acid group anionic gemini surfactant, comprising the steps of:

[0059] 1) In the presence of the first catalyst, the siloxane and the terminal acrylate are subjected to the first catalytic reaction for 4h to 5h at 70-90°C, and the molar ratio of siloxane to the terminal acrylate is 1:(1.1~1.5 ), the concentration of the first catalyst is 0.002 to 0.004% molar equivalent, preferably further vacuum distillation to obtain the first reaction intermediate, wherein the first catalyst is a platinum catalyst, and the platinum catalyst is more specifically chloroplatinic acid;

[0060]

[0061] 2) In an inert atmosphere, the first reaction intermediate is saponified in a sodium hydroxide solution for 4h to 5h at 25 to 40°C, wherein the molar ratio of the first reaction intermediate to sodium hydroxide is 1:(3- 8), then cooling, using 5wt% hydrochloric acid to adjust the pH value to 5, preferably followed by suc...

Embodiment 1

[0072] Ethylene-bis(N-ethylsulfonate-nonamethyltrialkoxyalkylamide)

[0073]

[0074] This embodiment provides the preparation method of the sulfonic acid group anionic gemini surfactant (ethylene-bis(N-ethylsulfonate-nonamethyltrialkoxypropionamide)) of the present application, which specifically includes the following steps:

[0075] 1) Synthesis of nonamethyltrisiloxane methyl propionate

[0076] Add 1mol nonamethyltrisiloxane and 1.2mol methyl acrylate into the reactor, heat up to 80°C under stirring, add chloroplatinic acid, carry out the first catalytic reaction for 4 hours, and distill under reduced pressure to obtain nonamethyltrisiloxane Methyl siloxane propionate;

[0077] 2) Synthesis of nonamethyltrisiloxane propionic acid

[0078] Under the protection of nitrogen, add 1mol nonamethyltrisiloxane methyl propionate, 4.0mol sodium hydroxide and 2000mL distilled water to the reactor, carry out 4h saponification reaction at room temperature, adjust the pH to 5 with...

Embodiment 2

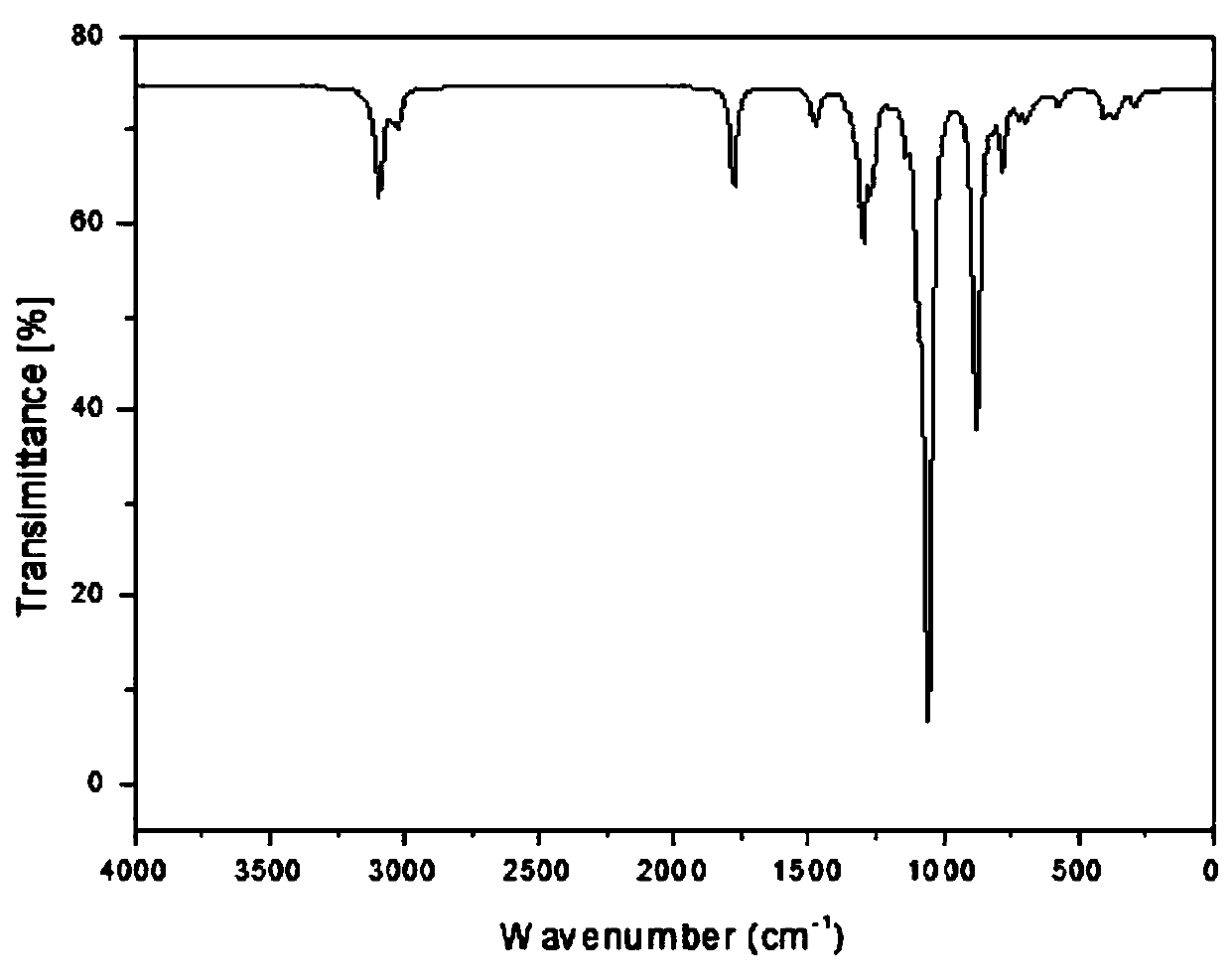

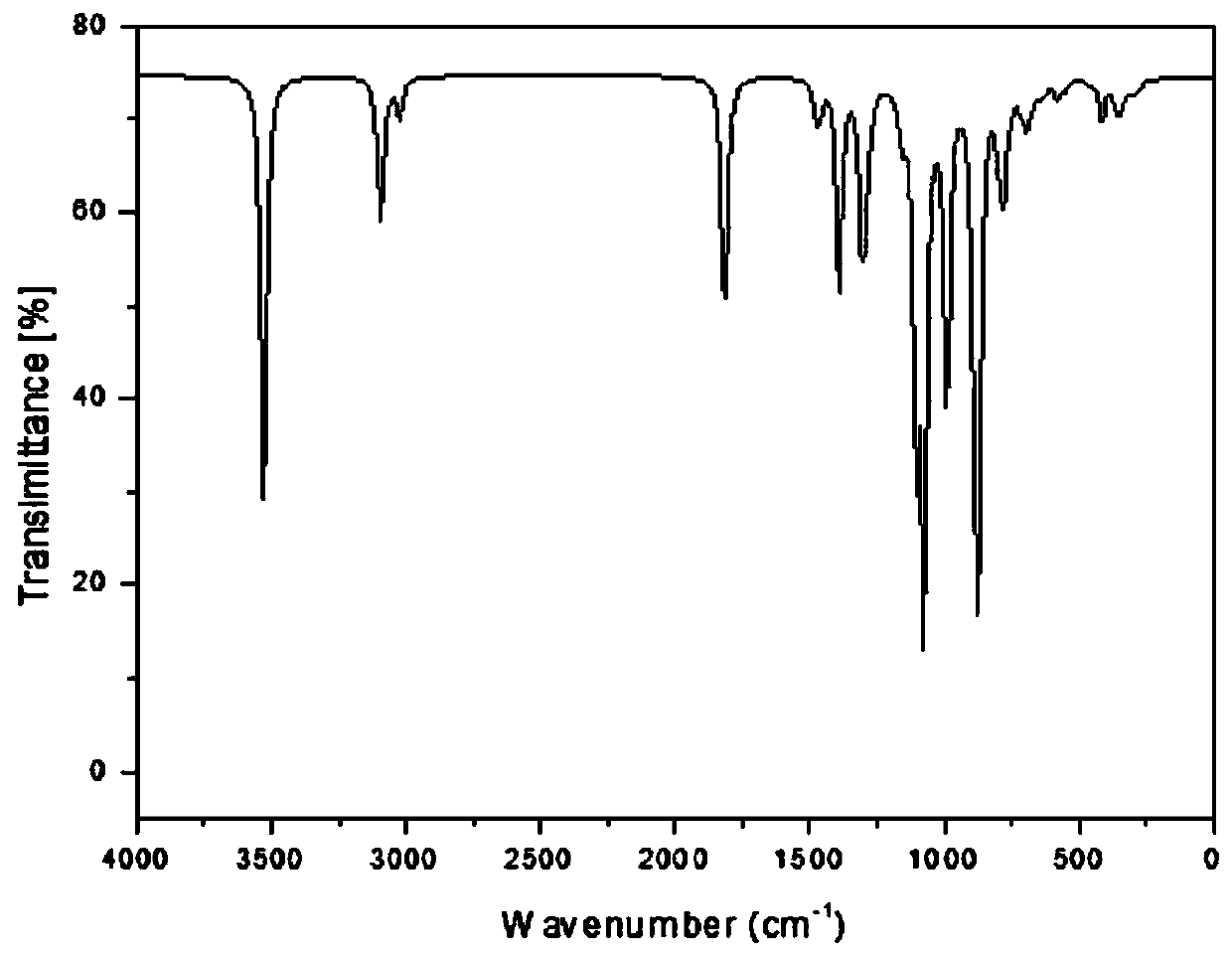

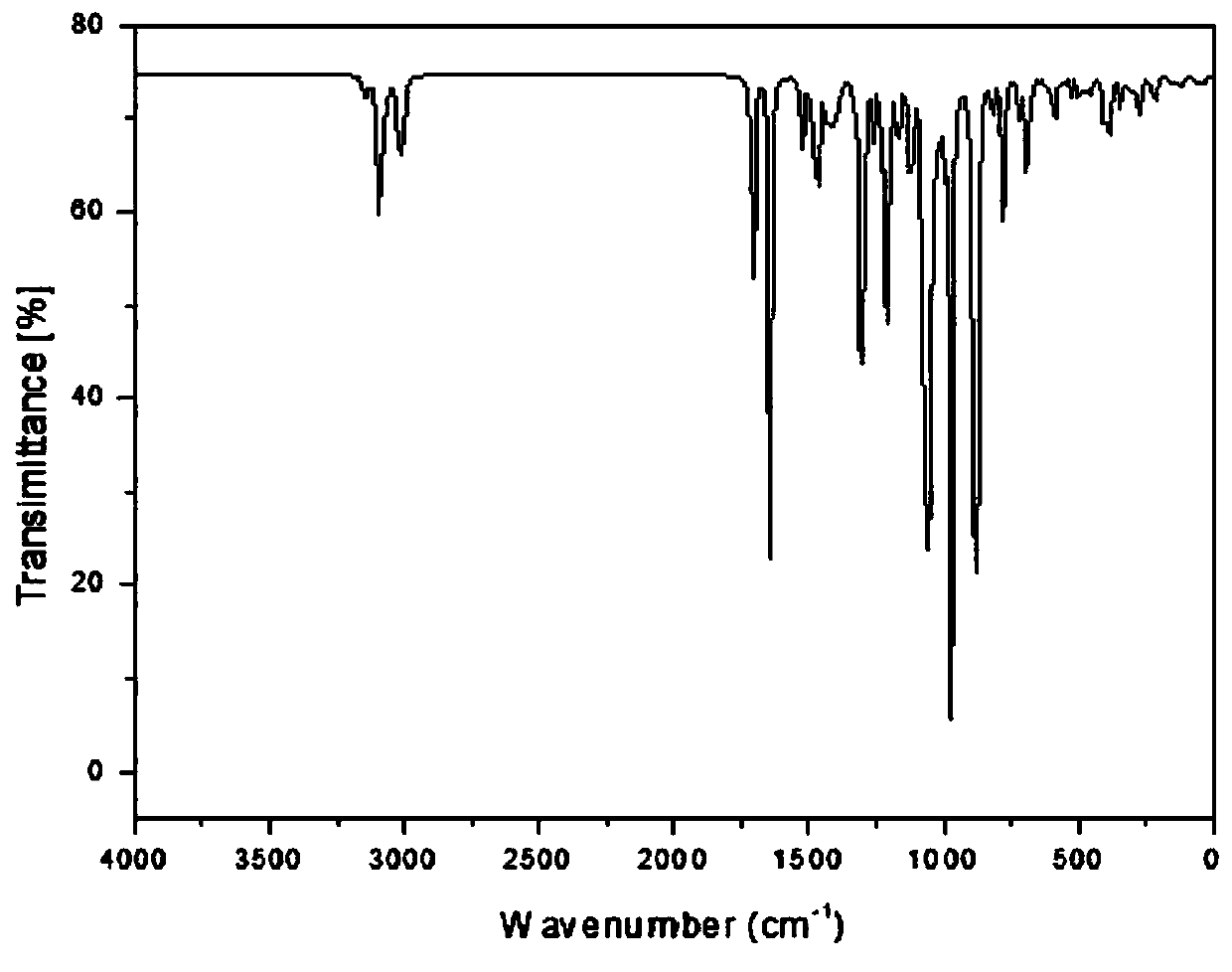

[0086] In this embodiment, the first reaction intermediate, the second reaction intermediate and the target product ethylene-bis(N-ethylsulfonate-nonamethyltrialkoxypropionamide) in the preparation process of Example 1 were infrared Spectral characterization, see results in Figure 1 to Figure 3 .

[0087] figure 1 (Namethyltrisiloxane methyl propionate): 3091.19cm -1 and 3090.08cm -1 Respectively CH 3 The antisymmetric stretching and plane rocking vibration peaks of ; 3051.03cm -1 and 3027.72cm -1 for -CH 2 -The antisymmetric and symmetric stretching vibration peaks; 1780.35cm -1 and 1328.14cm -1 It is the in-plane stretching vibration peak of C=O in -COOH; 1298.07cm -1 for -CH 2 - peaks of in-plane bending vibration and plane rocking vibration, 1064.04cm -1 The stretching vibration absorption peak of Si—O—Si (the peak is wide and strong), 874.20cm -1 It is the strong absorption peak of Si-C stretching vibration.

[0088] figure 2 (Namethyltrisiloxane propionic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com