Application of n-tetradecyl isopropanolamine as collecting agent in scheelite flotation

A technology of n-tetradecyl isopropanolamine and tetradecyl isopropanolamine is applied in the application field of n-tetradecyl isopropanolamine as a collector in scheelite flotation, and can It is not easy to solve the problems of collectors, the flotation effect of scheelite is not obvious, the chemical system and flotation process are complicated, etc., to achieve the effect of simple use process, simple chemical system, and simple use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In the present invention, the preparation method of described n-tetradecyl isopropanolamine preferably comprises the following steps:

[0025] adding the mixed liquid of propylene oxide and absolute ethanol into liquid tetradecylamine for addition reaction to obtain crude n-tetradecyl isopropanolamine;

[0026] The crude n-tetradecyl isopropanolamine is sequentially subjected to vacuum distillation, recrystallization, filtration, freezing and drying to obtain the n-tetradecyl isopropanolamine.

[0027] In the present invention, unless otherwise specified, the medicaments are commercially available products well known to those skilled in the art.

[0028] In the present invention, the mixed liquid of propylene oxide and absolute ethanol is preferably added dropwise into liquid tetradecylamine for addition reaction to obtain crude n-tetradecyl isopropanolamine. In the present invention, when tetradecylamine is solid, the method for obtaining the liquid tetradecylamine is...

preparation example

[0046] Drop the mixture of 0.21mol propylene oxide and 50mL absolute ethanol into 0.20mol liquid tetradecylamine at a rate of 5mL / h, and carry out addition reaction at 40°C for 13h to obtain crude n-tetradecyl Isopropanolamine;

[0047] After the crude n-tetradecyl isopropanolamine is distilled under reduced pressure at 80°C under the pressure of saturated water vapor pressure and 80°C, the distillation product is recrystallized with ethyl acetate and ethanol, and the obtained product is filtered The obtained solid product was filtered, frozen at -20° C. for 4 hours, and dried at 35° C. under vacuum for 12 hours to obtain the n-tetradecyl isopropanolamine.

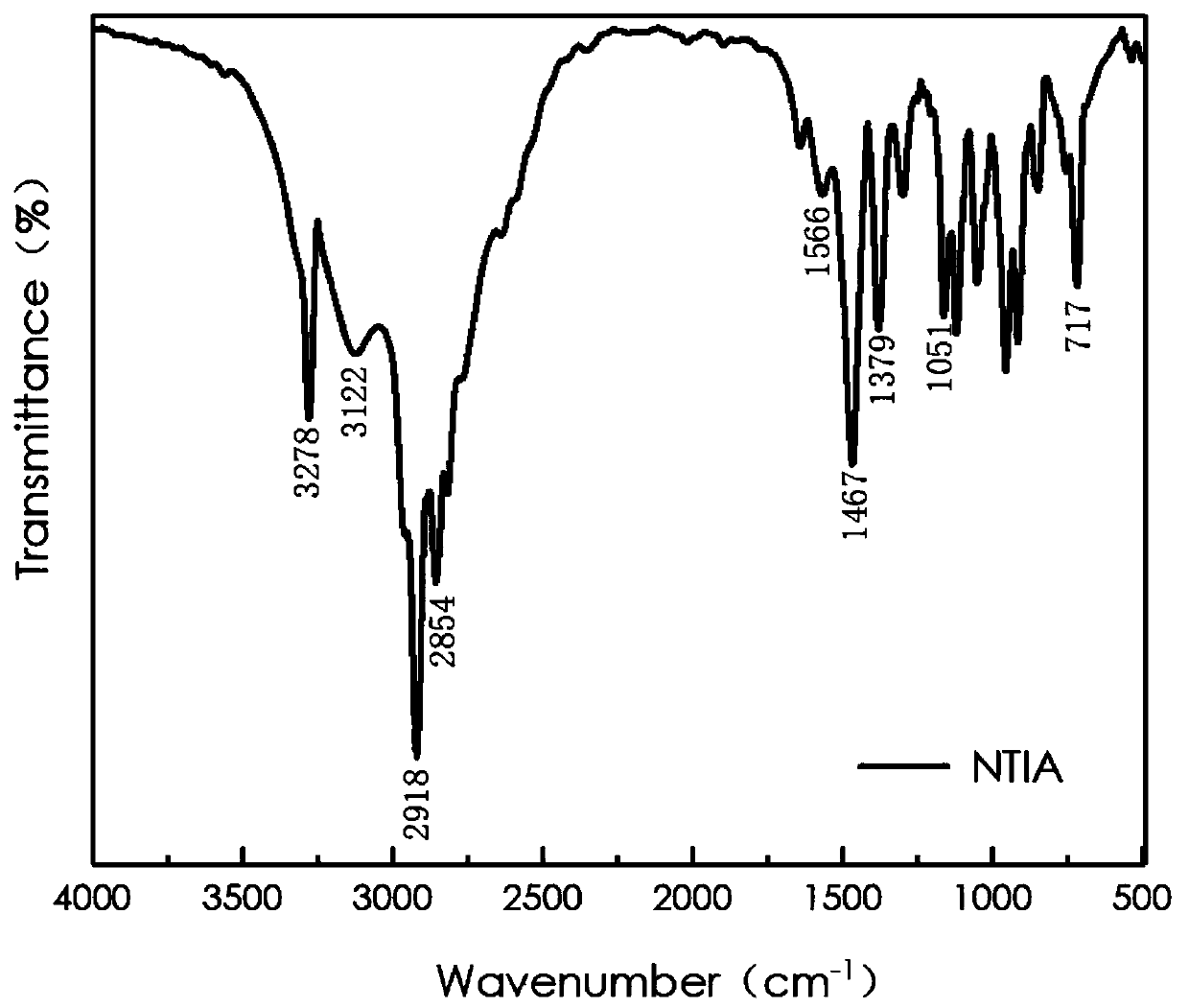

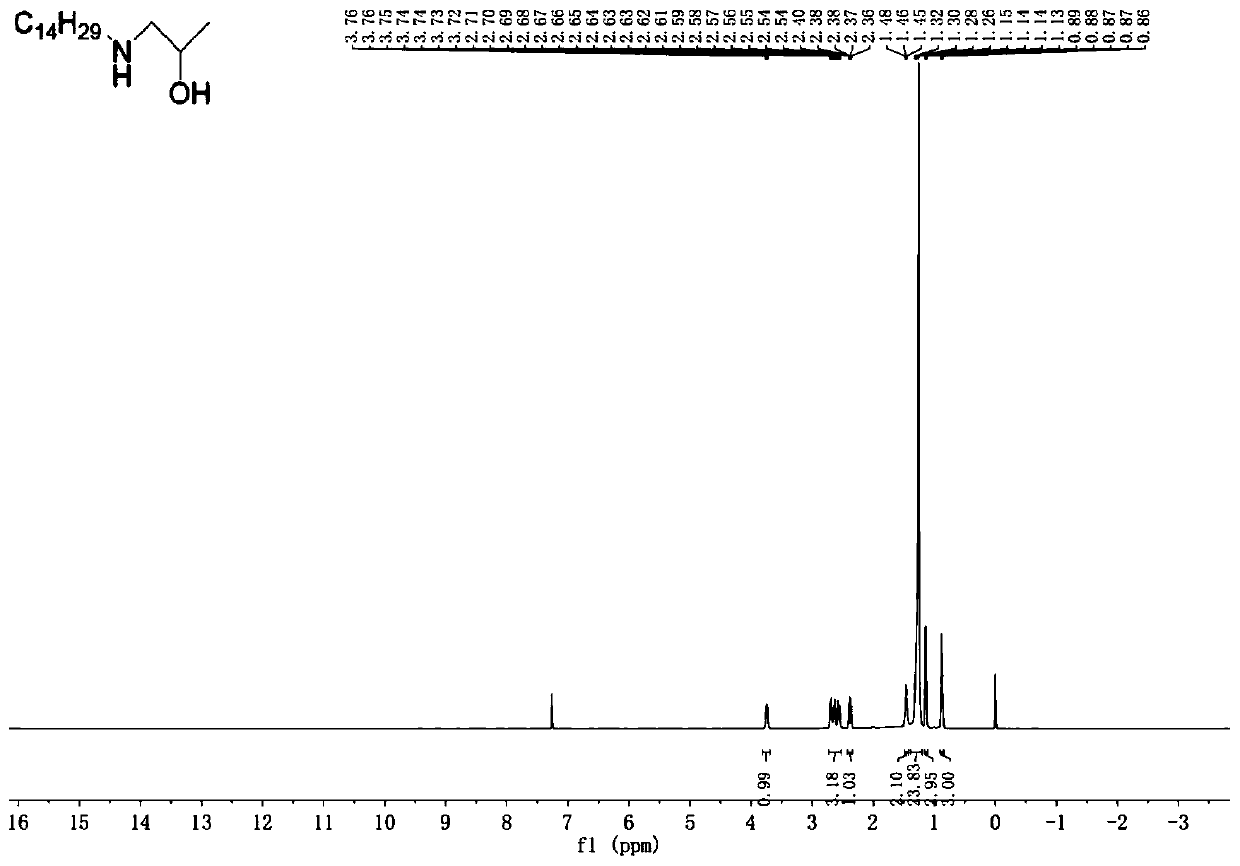

[0048] Infrared test is carried out to the n-tetradecyl isopropanolamine obtained in the preparation example, and the gained test chart is shown in figure 1 . The obtained n-tetradecyl isopropanolamine of the preparation example is carried out nuclear magnetic resonance, and the gained hydrogen spectrogram is shown in ...

Embodiment 1

[0050] Put 2g of scheelite ore sample into the flotation cell, according to the ratio of the mass of scheelite ore sample to the volume of deionized water is 1g: 18mL, add deionized water, use hanging cell flotation machine, at 1704rpm Stir for 2 min at lower temperature to obtain the primary slurry; at room temperature, use 1mol / L HCl solution and NaOH solution as the pH adjuster to adjust the pH value of the primary slurry to 6, and stir for 2 min at 1704 rpm to keep the pH value at 6. Obtain scheelite pulp;

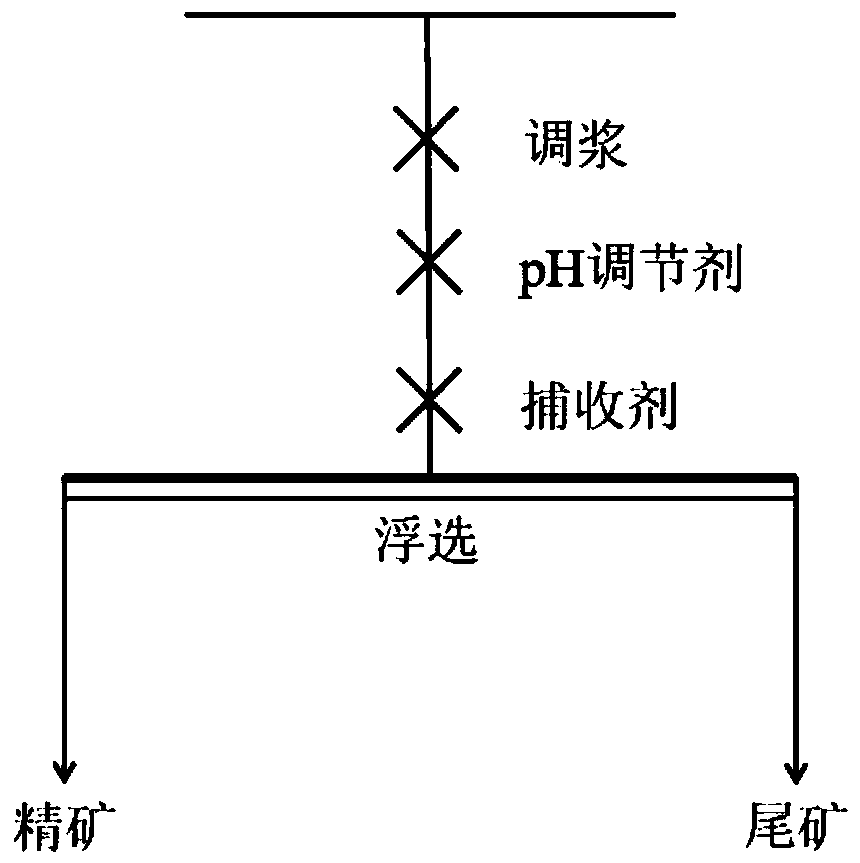

[0051] According to 50mg collector / 1L scheelite pulp, add collector n-tetradecyl isopropanolamine to the obtained scheelite pulp, stir at 1704rpm for 2min, then carry out mineral flotation scraping, flotation After 2min, concentrate ore (foam product) and tailings (product in the tank) are obtained; the process flow chart is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com