Water-based cutting fluid and preparation method thereof

A cutting fluid, water-based technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of water pollution, poor biodegradability, high cost, high lubricity, anti-rust ability, and good biodegradability , the effect of reducing the mass content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

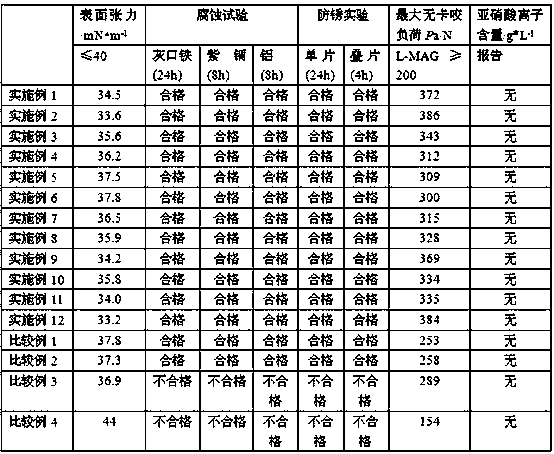

Examples

Embodiment 1

[0037] Take 100g of commercial tungoleic acid (purchased from Anhui Ruifengde Oil Deep Processing Co., Ltd., model: T160) into a 250mL four-neck flask, add 0.5g of tert-butylhydroquinone at the same time, purging with nitrogen for 30min, stirring at 300rpm, Raise the temperature to 220° C. for 4 h, stop heating, and cool to room temperature in ice water to obtain a crude product of dimer acid. The molecular distillation instrument controls the temperature at 150°C and the pressure ≤ 2Pa to collect the heavy component product; the heavy component product is distilled again, and the molecular distillation instrument is controlled to control the temperature at 250°C and the pressure ≤ 2Pa, and the outflowing light component is tung oil dimer acid, distillate Polyacid content ≥ 98%.

[0038]First, mix 4 parts of tung oil dimer acid and 1 part of triethanolamine, heat up to 110°C to react, stir until dissolved and transparent, and place it at room temperature, then add 2 parts of N...

Embodiment 2

[0040] Take 100g of commercial tungoleic acid (purchased from Anhui Ruifengde Oil Deep Processing Co., Ltd., model: T160) into a 250mL four-neck flask, add 0.5g of tert-butylhydroquinone at the same time, purging with nitrogen for 30min, stirring at 300rpm, Raise the temperature to 220° C. for 4 h, stop heating, and cool to room temperature in ice water to obtain a crude product of dimer acid. The molecular distillation instrument controls the temperature at 150°C and the pressure ≤ 2Pa to collect the heavy component product; the heavy component product is distilled again, and the molecular distillation instrument is controlled to control the temperature at 250°C and the pressure ≤ 2Pa, and the outflowing light component is tung oil dimer acid, distillate Polyacid content ≥ 98%.

[0041] First, mix 8 parts of tung oil dimer acid and 3 parts of triethanolamine, heat up to 130°C for reaction, stir until dissolved and transparent, place it at room temperature, then add 2.3 parts ...

Embodiment 3

[0043] Take 100g of commercial tungoleic acid (purchased from Anhui Ruifengde Oil Deep Processing Co., Ltd., model: T160) into a 250mL four-neck flask, add 0.5g of tert-butylhydroquinone at the same time, purging with nitrogen for 30min, stirring at 300rpm, Raise the temperature to 220° C. for 4 h, stop heating, and cool to room temperature in ice water to obtain a crude product of dimer acid. The molecular distillation instrument controls the temperature at 150°C and the pressure ≤ 2Pa to collect the heavy component product; the heavy component product is distilled again, and the molecular distillation instrument is controlled to control the temperature at 250°C and the pressure ≤ 2Pa, and the outflowing light component is tung oil dimer acid, distillate Polyacid content ≥ 98%.

[0044] First, mix 2 parts of tung oil dimer acid and 3 parts of triethanolamine, heat up to 120°C for reaction, stir until dissolved and transparent, place it at room temperature, then add 3 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com