Desulfurization wastewater treatment method and desulfurization wastewater treatment system

A technology for desulfurization wastewater and treatment method, which is applied in water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc. The process of preprocessing, the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

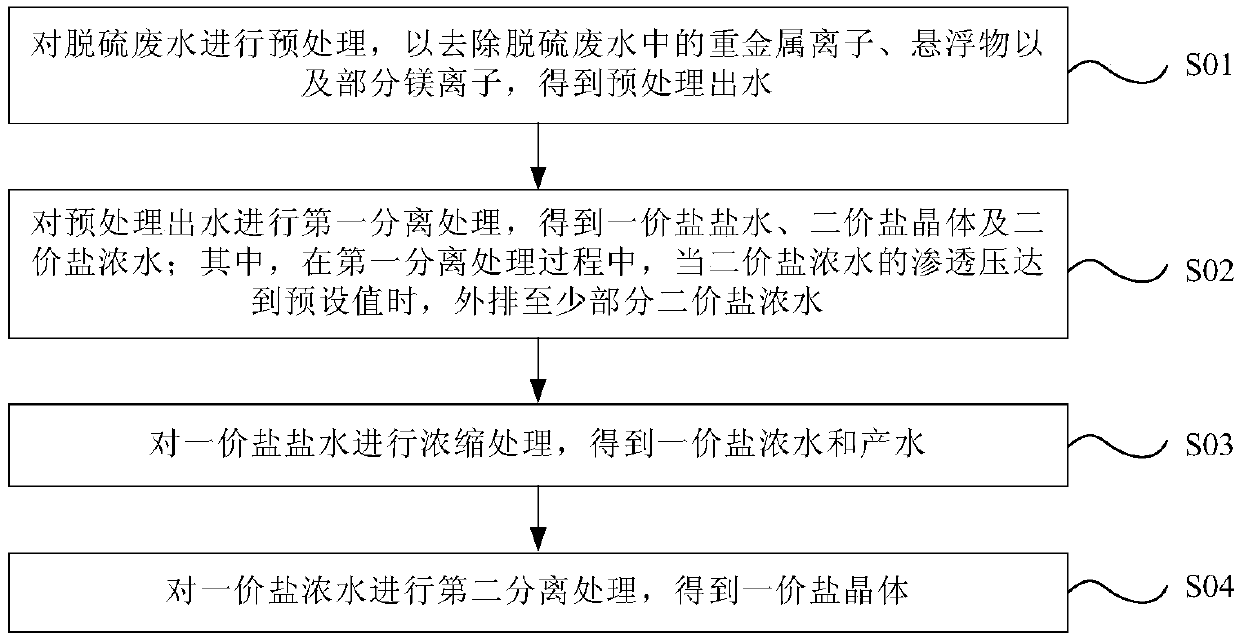

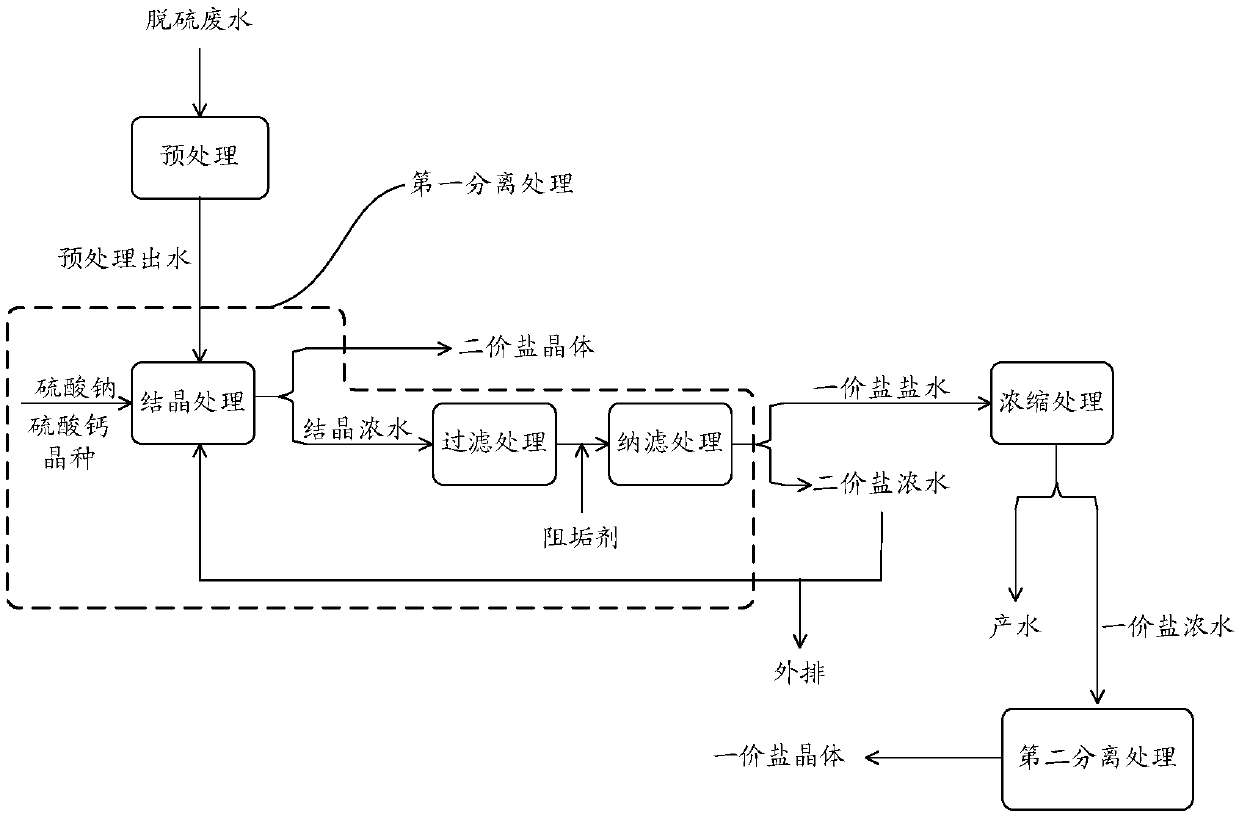

[0063] Such as figure 2 Shown, S02 includes first crystallization treatment and nanofiltration treatment again, namely:

[0064] (1) Carry out crystallization treatment to pretreatment effluent, obtain divalent salt crystal and crystal concentrated water;

[0065] (2) Nanofiltration treatment is performed on the concentrated crystallization water to obtain monovalent salt brine and divalent salt concentrated water.

[0066] Here, crystallization treatment is carried out to the pretreatment effluent, and divalent salt crystals (such as calcium sulfate crystals) can be obtained; nanofiltration treatment is carried out to the concentrated crystallized water obtained after crystallization treatment, that is, salt separation treatment, and monovalent salt brine and Divalent salt concentrated water (mainly magnesium ion concentrated water) for subsequent treatment.

[0067] The above-mentioned crystallization treatment may include, for example, room temperature crystallization tr...

example 2

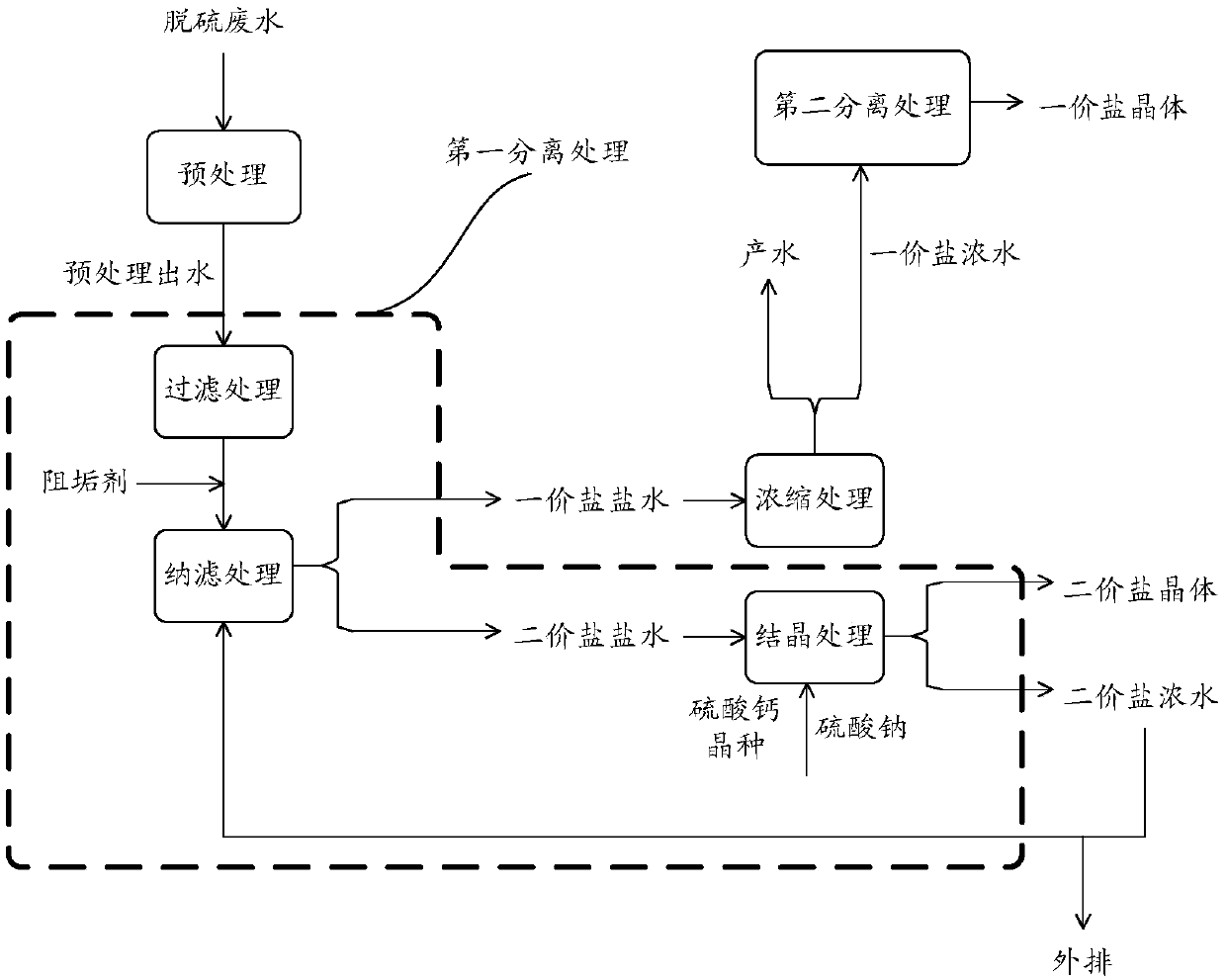

[0081] Such as image 3 Shown, S02 includes first nanofiltration treatment recrystallization treatment, namely:

[0082] (1) Nanofiltration treatment is performed on the pretreated effluent to obtain monovalent salt brine and divalent salt brine;

[0083] (2) Carrying out crystallization treatment on divalent salt brine to obtain divalent salt crystals and concentrated divalent salt water.

[0084] Here, the pretreatment effluent is subjected to nanofiltration treatment, that is, salt separation treatment, to obtain monovalent salt brine and divalent salt brine with calcium ions and magnesium ions intercepted; crystallization treatment of divalent salt brine to obtain divalent salt crystals (such as calcium sulfate crystals) and divalent salt concentrated water (mainly magnesium ion concentrated water) for subsequent treatment.

[0085] The above-mentioned crystallization treatment may include, for example, room temperature crystallization treatment, that is, crystallization...

Embodiment

[0140] The pretreatment unit used in this embodiment includes: a reaction tank and a clarification tank; the crystallization treatment subunit is a normal temperature crystallizer; the nanofiltration treatment subunit is composed of at least one nanofiltration membrane element; the concentration treatment unit is mainly composed of an electrodialysis device and a reverse The permeation device is composed; the second separation treatment unit is an evaporative crystallizer.

[0141] The specific process is as follows:

[0142] (1) Add the desulfurization wastewater discharged from the power plant to the reaction pool at a speed of 40T / h (ton / hour), add a certain amount of calcium hydroxide to the desulfurization wastewater, so that its pH value is adjusted to 10, and add to the adjusted A flocculant is added to the desulfurization wastewater, and then the reactants in the reaction tank are transported to the clarifier tank for sedimentation to obtain pretreated effluent;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com