Titanium-carbon foil preparation method and titanium-carbon foil for solid-state capacitor

A titanium carbon and aluminum foil technology, applied in the field of titanium carbon foil, can solve the problems of high hardware cost, high energy consumption, and long reaction time, and achieve the effects of ensuring phase formation and porosity, reducing reaction time, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

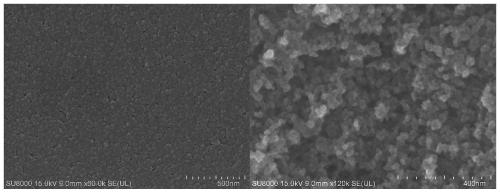

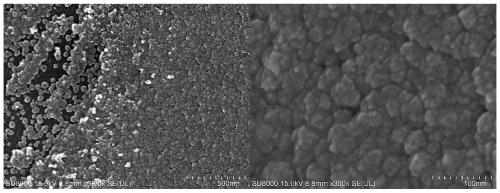

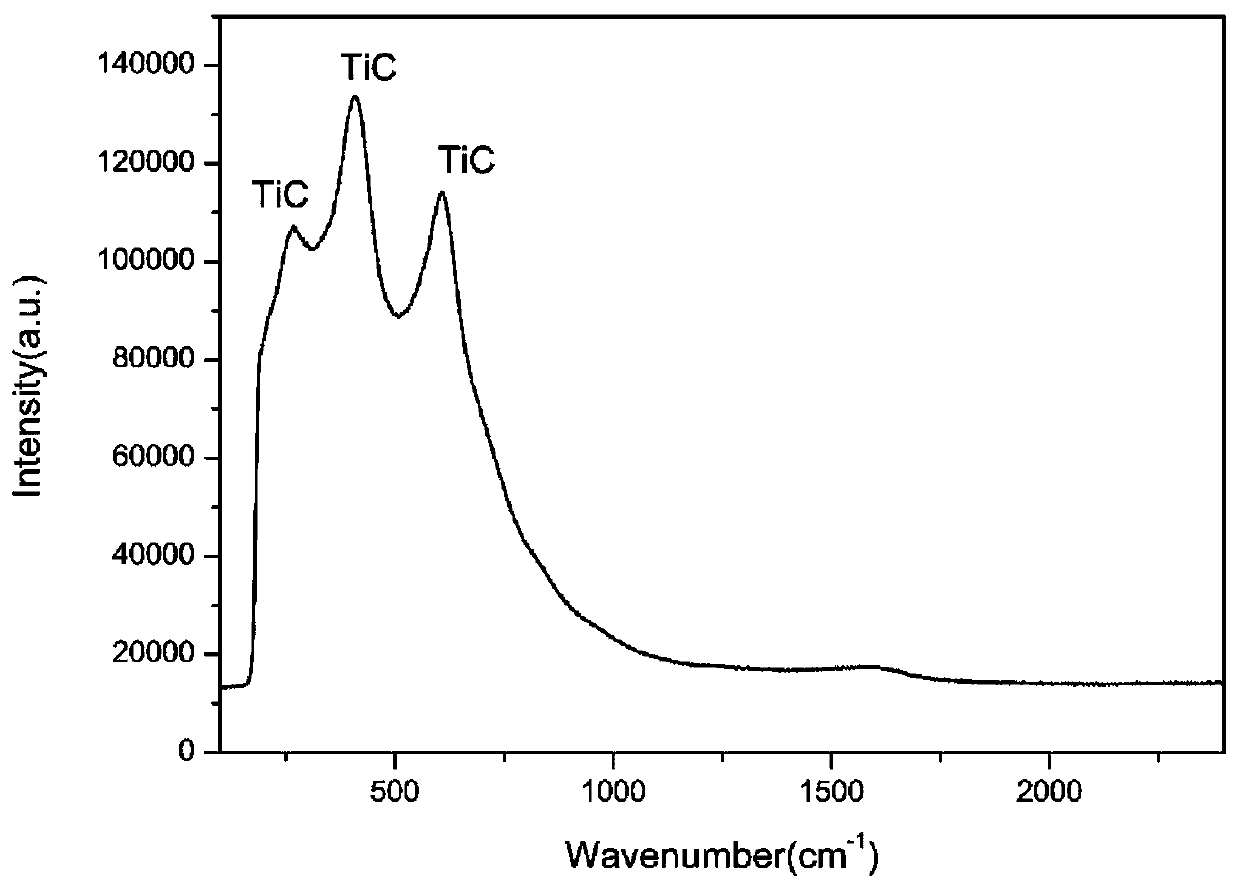

Image

Examples

Embodiment

[0034] The current preparation method of titanium carbon foil has the technical problems of high reaction temperature, high energy consumption, high preparation cost and long reaction time.

[0035] In order to solve the above technical problems, this embodiment provides a method for preparing titanium carbon foil, which includes the following steps:

[0036] S100, uniformly mixing polyvinylidene fluoride and a solvent containing -NR-functional group in proportion to prepare a reaction solution.

[0037] Wherein, the solvent containing -NR-functional group includes NMP, DMF, AN and aniline, and the weight ratio of NMP to polyvinylidene fluoride is 5%-10%.

[0038] S200. Put titanium tetrafluoride into the reaction solution under an inert gas environment, where the inert gas environment includes ultra-high-purity nitrogen and ultra-high-purity argon.

[0039] S300. After reacting within the set temperature range for a certain period of time, add glass ceramic powder and mix ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com