Metal-air battery anode component with conductive hydrophobic expanded polytetrafluoroethylene film and preparation method thereof

A technology of metal-air battery and polytetrafluoroethylene membrane, which is applied in the direction of electrical components, battery electrodes, fuel cell half-cells and secondary battery-type half-cells, etc., can solve the problem of poor wet storage performance, affecting discharge, and hole The size is not easy to control and other problems, to achieve the effect of strong hydrophobicity and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

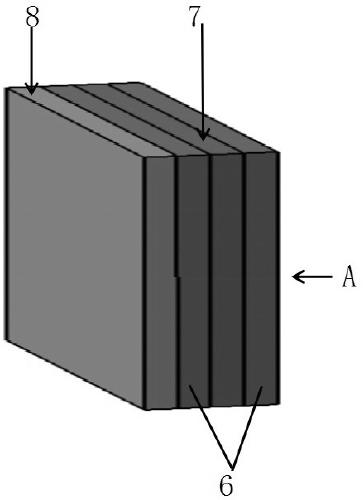

[0034] The present invention also relates to a method for preparing a positive electrode part of a metal-air battery with a conductive hydrophobic expanded polytetrafluoroethylene film, comprising the following steps:

[0035] 1) Prepare the catalytic layer, conductive hydrophobic expanded polytetrafluoroethylene PTFE membrane, conductive glue, metal or alloy mesh plate;

[0036] 2) Print or evenly distribute conductive glue on the adhesive surface of conductive hydrophobic expanded polytetrafluoroethylene PTFE film and metal or alloy mesh plate, and laminate them;

[0037]3) Press fastening and bonding, the pressure of pressing and fastening bonding is 0.01~0.3Mpa, and the preparation of the parts is completed after the final inspection is passed.

Embodiment 1

[0040] A conductive hydrophobic expanded polytetrafluoroethylene PTFE film comprises: 50wt%-70wt% polytetrafluoroethylene PTFE material and 30wt%-50wt% carbon.

[0041] Carbon includes a mixture of one or more of carbon black, graphene, carbon nanotubes, and carbon fibers.

[0042] The present invention selects polytetrafluoroethylene PTFE material as the base material, and the polytetrafluoroethylene PTFE material can be in the form of emulsion, powder, granules and the like.

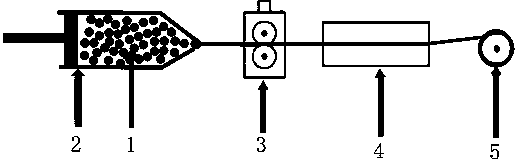

[0043] A kind of preparation method of conductive hydrophobic expanded polytetrafluoroethylene PTFE membrane, such as figure 2 shown, including the following steps:

[0044] 1) Put polytetrafluoroethylene PTFE fine powder and carbon into a transparent container with a size of 60cm×80cm and mix well, then slowly add 1100ml of lubricant, and mix well again, wherein the lubricant is kerosene, alkane and ethanol one or more mixtures;

[0045] 2) Push the uniformly mixed powder 1 into strips through the...

Embodiment 2

[0047] Embodiment 2: A conductive hydrophobic expanded polytetrafluoroethylene PTFE membrane, comprising: 60wt%~80wt% polytetrafluoroethylene PTFE material and 20wt%~40wt% pure metal powder.

[0048] The metal powder includes a mixed powder of one or more of nickel, copper and silver.

[0049] The present invention selects polytetrafluoroethylene PTFE material as the base material, and the polytetrafluoroethylene PTFE material can be in the form of emulsion, powder, granules and the like.

[0050] A kind of preparation method of conductive hydrophobic expanded polytetrafluoroethylene PTFE membrane, such as figure 2 shown, including the following steps:

[0051] 1) Put polytetrafluoroethylene PTFE fine powder and metal powder into a transparent container with a size of 60cm×80cm and mix well, then slowly add 800ml of lubricant, and mix well again, wherein the lubricant is kerosene, alkane and ethanol One or more mixtures of

[0052] 2) Push the uniformly mixed powder 1 into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com