A method and system for producing synthesis gas from biomass

A technology for synthesis gas and biomass, which is applied in the manufacture of combustible gas, gasification process, petroleum industry, etc., can solve the problems of needing deashing and impurity treatment, increasing process flow, etc., so as to enhance the anti-deactivation ability, ensure the purity, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

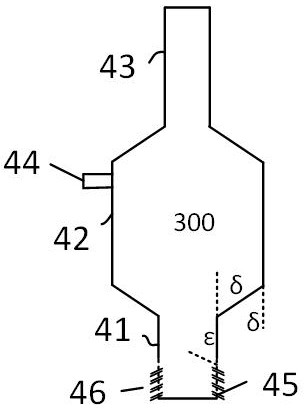

[0061] The preparation of the catalyst used in the embodiment of the invention

[0062] According to the molar ratio of ferric nitrate, nickel nitrate and titanium chloride 1:0.5:0.1, weigh 1.0 mol of ferric nitrate, 0.5 mol of nickel nitrate and 0.1 mol of titanium chloride to prepare a 2L solution, and then mix the metal salt prepared above The solution is mixed evenly with citric acid and ethylene glycol according to the molar ratio (the molar ratio of metal ions, citric acid and ethylene glycol) 1:2.5:3.5, and then the temperature is raised to 80°C for stirring reaction, and as the water evaporates, a condensate is formed The gel state substance was vacuum dried for 24 hours, then calcined at 800°C for 20 hours, and then pulverized to 120µm after natural cooling to obtain the active component of the catalyst. Further according to the mass percentage content, the active component is 6wt%, olivine 69wt%, bio-tar 5wt%, water 20wt%, after the above-mentioned substances are ful...

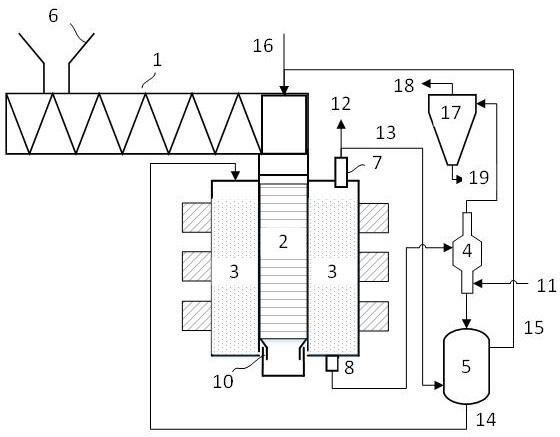

Embodiment 1

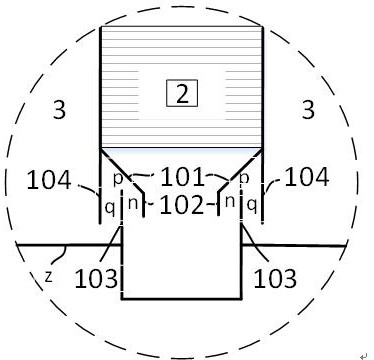

[0065] The pretreated biomass raw material with a size of 10mm enters the microwave pyrolysis section through the biomass feeding bin, and stops feeding when the biomass raw material fills up to the range irradiated by the microwave pyrolysis section, and then sets the microwave power density of the microwave pyrolysis section 1×10 5 W / m 3 , when the temperature of the microwave pyrolysis section reaches 500°C, the biomass raw material (10kg / h) is re-introduced, and the biomass raw material is controlled to react in the microwave pyrolysis section for 10 minutes. After microwave pyrolysis treatment, the pyrolysis products of biomass are mainly pyrolysis volatile components and part of bio-semi-char, of which the pyrolysis volatile components account for 76wt%, and the non-condensable gases in the pyrolysis volatile components The content reaches 78%. Pyrolysis volatile components and bio-semi-coke are sent to the microwave gasification section, under the action of feeding wo...

Embodiment 2

[0067] The pretreated biomass raw material with a size of 10mm enters the microwave pyrolysis section through the biomass feeding bin, and stops feeding when the biomass raw material fills up to the range irradiated by the microwave pyrolysis section, and then sets the microwave power density of the microwave pyrolysis section 2×10 5 W / m 3 , when the temperature of the microwave pyrolysis section reaches 600°C, the biomass raw material (10kg / h) is re-introduced, and the biomass raw material is controlled to react in the microwave pyrolysis section for 10 minutes. After microwave pyrolysis treatment, the pyrolysis products of biomass are mainly pyrolysis volatile components and part of bio-semi-char, of which pyrolysis volatile components account for 80%, and non-condensable gases in pyrolysis volatile components The content reaches 85%. Pyrolysis volatile components and bio-semi-coke are sent to the microwave gasification section, under the action of feeding working gas and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com