A kind of acrylate emulsion for pvc floor glue and preparation method

An acrylate and floor adhesive technology, applied in the direction of adhesives, ester copolymer adhesives, adhesive types, etc., can solve the problems of poor initial viscosity, stability difference, delay in work and time, etc., and improve the sticking performance. , Adhesion improvement, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

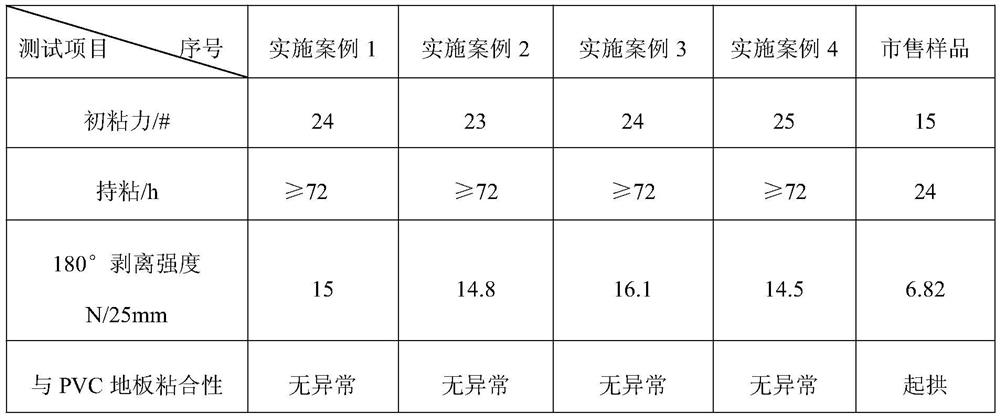

Examples

Embodiment 1

[0031] An acrylic ester emulsion for PVC floor glue, comprising 70 parts by weight of deionized water; 0.5 part of linear alkylbenzene sulfonate; 0.25 part of allyl polyether phosphate; nonylphenol polyoxyethylene ether 1.5 parts; 80 parts of n-butyl acrylate; 10 parts of acrylonitrile; 3 parts of methacrylic acid; 0.05 parts of n-dodecanethiol; 0.1 parts of ammonium bicarbonate; 0.2 parts of L-ascorbic acid; 1.5 parts of ammonia water.

[0032] The preparation method of acrylic acid ester emulsion for described PVC floor glue, comprises the following steps:

[0033] a) Preparation of primer A: at room temperature, add 30% of the total amount of deionized water, 2% of the total amount of emulsifier and all ammonium bicarbonate to the reactor, and raise the temperature in the reactor to 82°C;

[0034] b) Preparation of monomer solution B: under normal temperature and pressure, mix the remaining emulsifier, 45% of the total amount of deionized water, n-butyl acrylate, acrylonit...

Embodiment example 2

[0039] An acrylic ester emulsion for PVC floor glue, comprising 65 parts by weight of deionized water; 0.4 parts of fatty alcohol ether sulfates; 0.2 parts of vinyl sulfonates; 1.2 parts of alkyl alcohol block polyethers; 90 parts of isobutyl ester; 5 parts of acrylonitrile; 2 parts of acrylic acid; 1 part of monobutyl itaconate; 0.2 parts; 0.3 parts of sodium bisulfite; 1 part of sodium hydroxide.

[0040] The preparation method of acrylate emulsion for PVC floor glue of the present invention comprises the following steps:

[0041] a) Preparation of primer A: at room temperature, add 25% of the total amount of deionized water, 2.5% of the total amount of emulsifier and all sodium bicarbonate to the reactor, and raise the temperature in the reactor to 83°C;

[0042] b) Preparation of monomer solution B: under normal temperature and pressure, the remaining emulsifier, 50% of the total amount of deionized water, isobutyl acrylate, acrylonitrile, acrylic acid, monobutyl itaconat...

Embodiment example 3

[0047] An acrylic ester emulsion for PVC floor glue, comprising 65 parts by weight of deionized water; 0.4 part of fatty alcohol ether sulfates; 0.2 part of allyl polyether phosphate; 1.2 parts of nonylphenol polyoxyethylene ether ; 80 parts of isooctyl acrylate; 10 parts of acrylonitrile; 2 parts of methacrylic acid; 1 part of monobutyl itaconate; 0.15 parts of formyl; 0.2 parts of L-ascorbic acid; 1.5 parts of ammonia water.

[0048] The preparation method of acrylate emulsion for PVC floor glue of the present invention comprises the following steps:

[0049] a) Preparation of primer A: at room temperature, add 30% of the total amount of deionized water, 2% of the total amount of emulsifier and all sodium carbonate to the reactor, and raise the temperature in the reactor to 82°C;

[0050] b) Preparation of monomer solution B: under normal temperature and pressure, the remaining emulsifier, 50% of the total amount of deionized water, isooctyl acrylate, acrylonitrile, methacr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com