Method for producing 1,3-propylene glycol through glycerol fermentation via microorganisms

A technology of microorganisms and glycerin, applied in the field of bioengineering, can solve the problems of low conversion rate and high production cost, and achieve the effect of increasing conversion rate and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

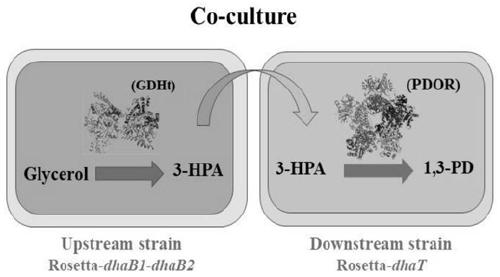

Method used

Image

Examples

Embodiment 1

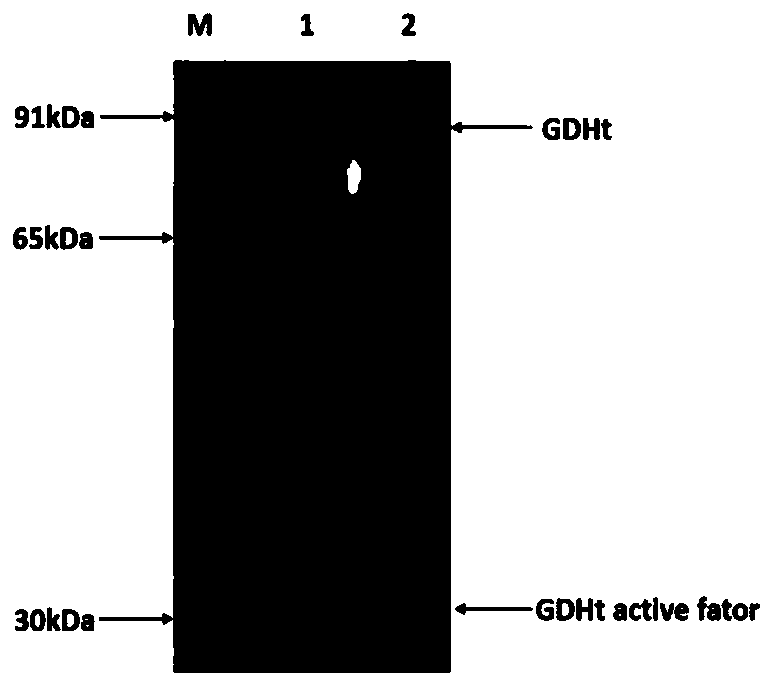

[0033] 1. Construction and expression of recombinant Escherichia coli Rosseta-dhaB1dhaB2

[0034] 1) According to the gene sequence of the related glycerol dehydratase (GDHt) and glycerol dehydratase activator (GDHt active factor) of Clostridium butyricum VPI 1718 (GenBank number: AY112989) and the characteristics of the multiple cloning site of the expression vector pANY1, using biological information Synthetic primers designed by the scientific software NTI are: upstream primer F: 5'- GGGGGATCCACTAGTAGGCCT ATGATAAGTAAAGGATTTAG-3' and downstream primer R:5'- CAGGAGCTCCCATGGAGGCCT TTAATGATGATGATGATGGTGCTCAGCTCCAATTGTGCAAG-3', the underlined part is the StuI restriction site, and the wavy part is the upstream and downstream homology arms homologous to the pANY1 plasmid;

[0035] 2) Use Clostridium butyricum YJH-09 genomic DNA as a template to amplify the target gene by PCR. PCR amplification reaction parameters: pre-denaturation: 95°C for 5min, denaturation: 94°C for 2min, a...

Embodiment 2

[0052] Determination of glycerol dehydratase activity:

[0053] 1) Take an appropriate amount of the Rosseta-dhaB1dhaB2 bacterium liquid that has been successfully expressed in Example 1, centrifuge at 4°C for 10 min, collect the bacteria sludge, wash twice with 0.1mol / L potassium phosphate buffer solution of pH 7.4, and wash with an appropriate amount of potassium phosphate after centrifugation The bacteria were resuspended in the buffer, ultrasonically disrupted in an ice bath, centrifuged at 10,000 rpm, 4°C for 10 min, and the supernatant was the crude enzyme solution.

[0054] 2) Determination method of glycerol dehydratase activity: under optimum temperature and optimum pH conditions, according to the above reaction, the amount of enzyme needed to catalyze the generation of 1 μmoL propionaldehyde per minute is defined as one enzyme activity unit. Measured by MBTH (3-methyl-2-benzothiazolinone hydrazine) method, GDHt can catalyze the substrate glycerin (or 1,2-propanediol)...

Embodiment 3

[0057] Determination of 1,3-propanediol dehydrogenase activity:

[0058] 1) Take an appropriate amount of the Rosseta-dhaT bacterial liquid successfully expressed in Example 1, centrifuge at 4°C for 10 min, collect the bacterial sludge, wash twice with 0.1mol / L potassium phosphate buffer solution of pH 7.4, and wash with an appropriate amount of potassium phosphate after centrifugation The bacteria were resuspended in the buffer, ultrasonically disrupted in an ice bath, centrifuged at 10,000 rpm, 4°C for 10 min, and the supernatant was the crude enzyme solution.

[0059] 2) Determination of 1,3-propanediol dehydrogenase reductive activity: under the optimal temperature and optimal pH conditions, according to the above reaction, the amount of enzyme required to generate 1 μmoL 1,3-PD per minute is defined as an enzyme activity unit . In a total volume of 1.0mL, mix the following components according to the final concentration: 27mmol / L propionaldehyde, 0.37mmol / L NADH, 35mmol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com