Preparation method of MoS2 quantum dot loaded nano TiO2

A quantum dot and nano technology, applied in the field of photocatalytic materials, can solve the problems of low catalytic rate, inability to achieve sterilization and self-cleaning, etc., and achieve the effect of improving catalytic efficiency, good in-situ dispersion characteristics, and improving visible light activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] MoS of this example 2 Quantum dot loaded nano TiO 2 The preparation method comprises the following steps:

[0028] (1) Mix and grind nano-titanium dioxide, molybdenum disulfide and chitosan according to the ratio of 75:1:2 for 20 minutes to obtain mixed powder;

[0029] (2) Add N-methylpyrrolidone to the mixed powder, stir and mix to obtain a mixed solution, wherein the mass ratio of nano-titanium dioxide to N-methylpyrrolidone is 1:100;

[0030] (3) Put the mixture in an ultrasonic cleaning machine for 1 hour, and the power of ultrasonic treatment is 250W;

[0031] (4) Heat the ultrasonically treated mixture to 120°C and react for 3 hours;

[0032] (5) Evaporate the heat-treated mixed solution at 100°C until it becomes powder.

[0033] In the embodiment of the present invention, the molybdenum disulfide and chitosan powders were purchased from Aladdin Reagents, and the P25 nano-titanium dioxide was purchased from Evonik Industrial Group.

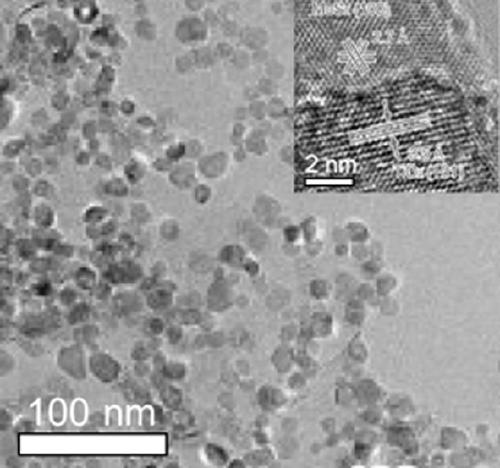

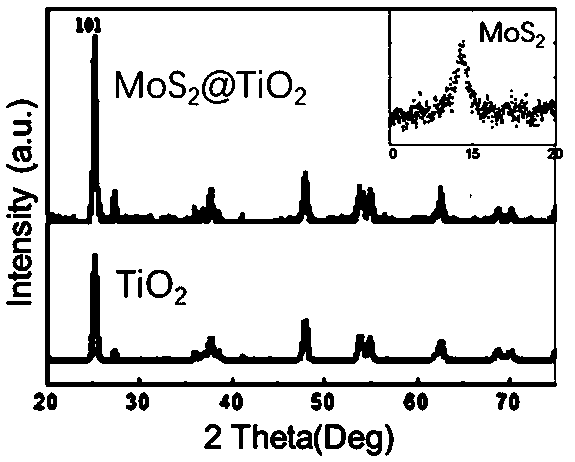

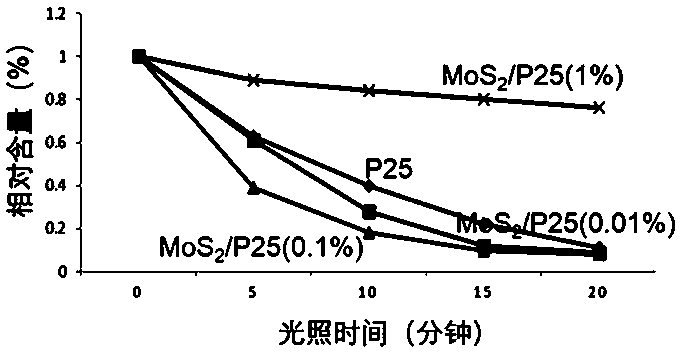

[0034] The MoS2@TiO2 nan...

Embodiment 2

[0040] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0041] (1) Grinding nano titanium dioxide, molybdenum disulfide and chitosan for 30 minutes to obtain mixed powder;

[0042] (2) The mass ratio of nano-titanium dioxide to N-methylpyrrolidone is 1:1000;

[0043] (3) Ultrasonic treatment for 0.5 hours, the power of ultrasonic treatment is 200W;

[0044] (4) Heat treatment to 110°C and react for 2 hours;

[0045] (5) Evaporate to dryness at 80°C until it becomes powder.

Embodiment 3

[0047] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0048] (1) Grinding nano titanium dioxide, molybdenum disulfide and chitosan for 10 minutes to obtain mixed powder;

[0049] (2) The mass ratio of nano titanium dioxide to N-methylpyrrolidone is 1:10;

[0050] (3) Ultrasonic treatment for 2 hours, the power of ultrasonic treatment is 300W;

[0051] (4) Heat treatment to 140°C and react for 4 hours;

[0052] (5) Evaporate to dryness at 90°C until it becomes powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com