A kind of polyurethane emulsion and anti-reflection coating solution prepared therefrom

A polyurethane emulsion, anti-reflection technology, applied in the direction of polyurea/polyurethane coatings, reflective/signal coatings, coatings, etc., can solve the problems of restricting the type of polyurethane used, poor wear resistance and weather resistance of coatings, and achieve compatibility The effect of good, good wear resistance and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Prepare polyurethane emulsion, the steps are as follows:

[0096] 1) Take 89.47g of PPG6000 (two functional groups) after vacuuming to remove water (Dow Chemical, hydroxyl content 0.03mol), 33.6g isophorone diisocyanate (Wanhua Chemical, NCO content 0.3mol), catalyst dilauric acid 0.020 g of dibutyltin was added to the reactor, and mixed and stirred at 50° C. for 2 hours.

[0097] 2) Dissolve 18.52g of chain extender 2,2-dimethylolbutanoic acid (hydroxyl content: 0.25mol) into 92.83g of solvent N-methylpyrrolidone, then slowly add to the above solution, at a temperature of 50°C, The reaction was continued for 2 hours.

[0098] 3) Add neutralizing agent ammonia 17.52g (25% concentration) to above-mentioned solution, after stirring evenly, then add it into 1074.14g deionized water emulsification and obtain the nano polyurethane emulsion of solid content 12%.

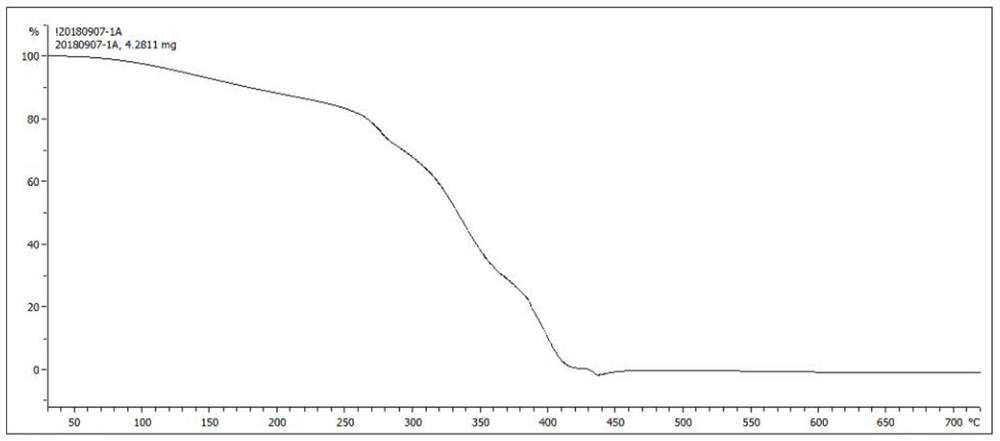

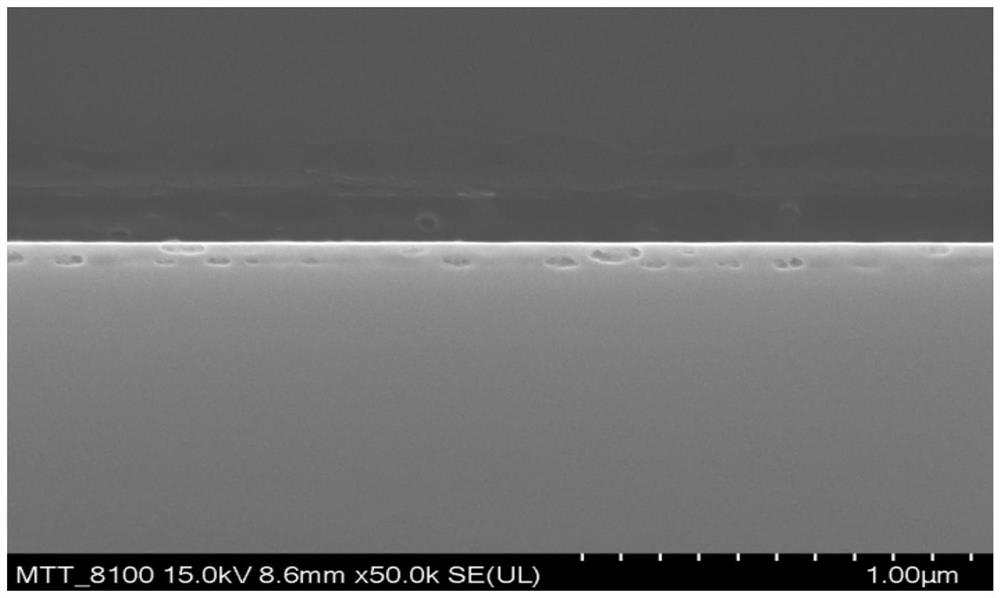

[0099] Its particle size was tested to be 100nm. The thermal decomposition residual rate of the polyurethane e...

Embodiment 2

[0104] Prepare polyurethane emulsion, the steps are as follows:

[0105] 1) Take 14.83g of polyether polyol PPG-600 (2 functional groups) after vacuuming to remove water (Dow Chemical, hydroxyl content 0.05mol), 25.07g diphenylmethane diisocyanate (BASF M20S, NCO content 0.2mol), The catalyst, 0.024 g of dibutyltin diacetate, was added to the reactor, and mixed and stirred at 50° C. for 4 hours.

[0106] 2) Dissolve 55.56g of chain extender 2,2-dimethylolbutanoic acid (0.75mol of hydroxyl content) into 78.51g of solvent propylene glycol butyl ether, then slowly add to the above solution, and continue the reaction at a temperature of 50°C 2 hours.

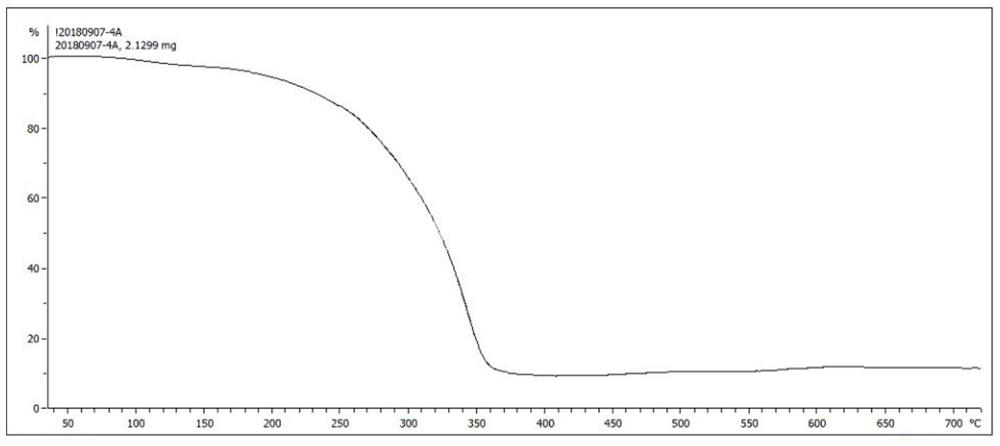

[0107] 3) Add neutralizing agent 105.16g ammonia water (25% concentration) to above-mentioned solution, after stirring evenly, then add it into 593.21g deionized water emulsification and obtain the nano polyurethane emulsion of solid content 23%. Its particle size was tested to be 50nm. The thermal decomposition residual rate was...

Embodiment 3

[0112] 1) Take 124.12g of polyether polyol PPG-2000 (two functional groups) after vacuuming to remove water (Dow Chemical, hydroxyl content 0.125mol), 428.57g of hexamethylene diisocyanate-based polyisocyanate (Wanhua Chemical HT-90B , NCO content 2mol), 0.1934g of catalyst tin octoate was added into the reactor, and mixed and stirred at 50°C for 2 hours.

[0113] 2) Dissolve 37.04g of chain extender 2,2-dimethylolbutanoic acid (hydroxyl content: 0.5mol) into 377.09g of solvent ethyl acetate, then slowly add to the above solution, and continue the reaction at a temperature of 50°C 2 hours.

[0114] 3) Add 10 g of neutralizing agent sodium hydroxide to the above solution, stir evenly, then add it into 2452.12 g of deionized water for emulsification to obtain a nano polyurethane emulsion with a solid content of 17.5%.

[0115] Its particle size was tested to be 80nm. The thermal decomposition residual rate was tested by thermogravimetric analysis equipment, and the residual ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com