Method for preparing simple substance palladium thin film through atomic layer deposition technology

An atomic layer deposition, elemental palladium technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of reducing deposition temperature, inconvenient process for hydrogen storage and use safety, poor coating effect, etc. , to achieve the effect of simplifying the preparation process, easy operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

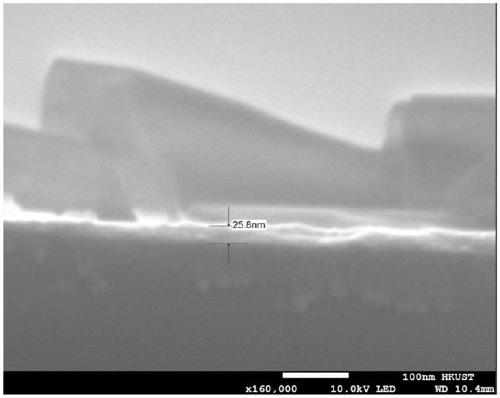

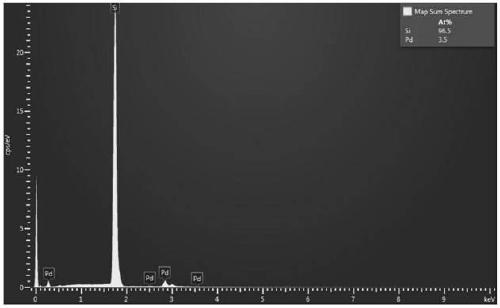

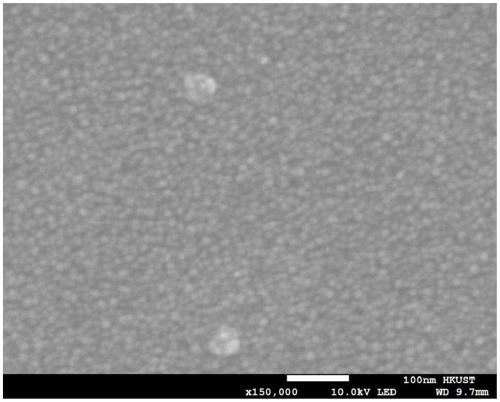

[0032] A kind of with palladium hexafluoroacetylacetonate Pd (hfac) 2 as palladium precursor, the method for preparing elemental palladium thin film with propylhydrazine as the atomic layer deposition technology of hydrazines reducing precursor, comprises the following steps:

[0033] S1. Heat the atomic layer deposition equipment to a temperature of 200°C, and the ultimate pressure after vacuuming is 0.1-10Pa;

[0034] S2. The average heating temperature of the atomic layer deposition system is 200°C, the pressure value is 10-200Pa, the heating time is 40min, and the flow rate range of the carrier gas is 10-200sccm;

[0035] S3. Open the palladium hexafluoroacetylacetonate atomic layer deposition pulse valve, and the opening time range of the pulse valve is 50-2000ms, so that the palladium hexafluoroacetylacetonate enters the equipment reaction chamber, adsorbs and reacts with the substrate surface;

[0036] S4. Use an inert gas as the carrier gas to clean the incompletely re...

Embodiment 2

[0042] A kind of with palladium hexafluoroacetylacetonate Pd (hfac) 2 as palladium precursor, the method for preparing elemental palladium thin film with t-butylhydrazine as the atomic layer deposition technique of hydrazines reducing precursor, comprises the following steps:

[0043] S1. Heat the atomic layer deposition equipment to a temperature range of 300°C, and the ultimate pressure after vacuuming is 0.1-10Pa;

[0044] S2. The average heating temperature range of the atomic layer deposition system is 300°C, the pressure range is 10-200Pa, the heating time is 40min, and the flow rate range of the carrier gas is 10-200sccm;

[0045] S3. Open the palladium hexafluoroacetylacetonate atomic layer deposition pulse valve, and the opening time range of the pulse valve is 50-2000ms, so that the palladium hexafluoroacetylacetonate enters the equipment reaction chamber, adsorbs and reacts with the substrate surface;

[0046] S4. Use an inert gas as the carrier gas to clean the inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com