Two-dimensional layered perovskite ferroelectric multifunctional film and preparation process thereof

A two-dimensional layered, perovskite technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of difficult regulation of polarization direction, difficult research and development of reliable processes, and difficult to promote, etc. control, low cost, and excellent ferroelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

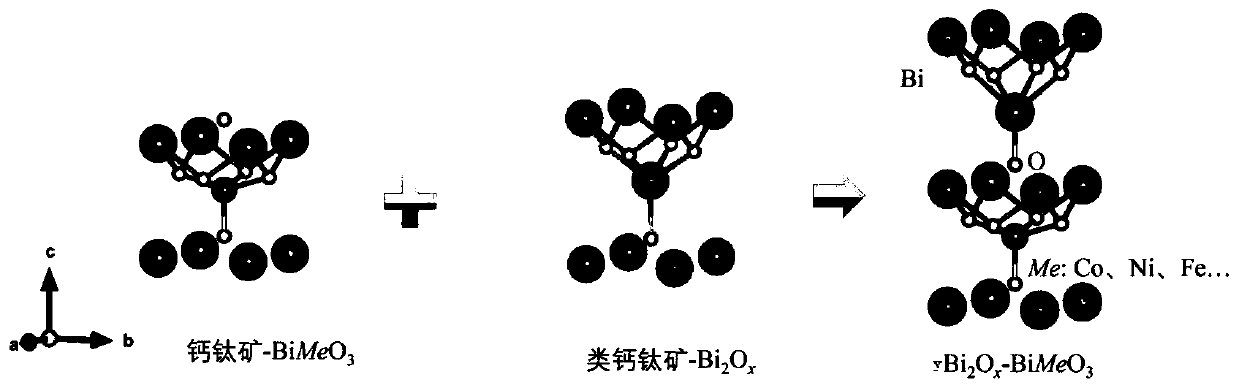

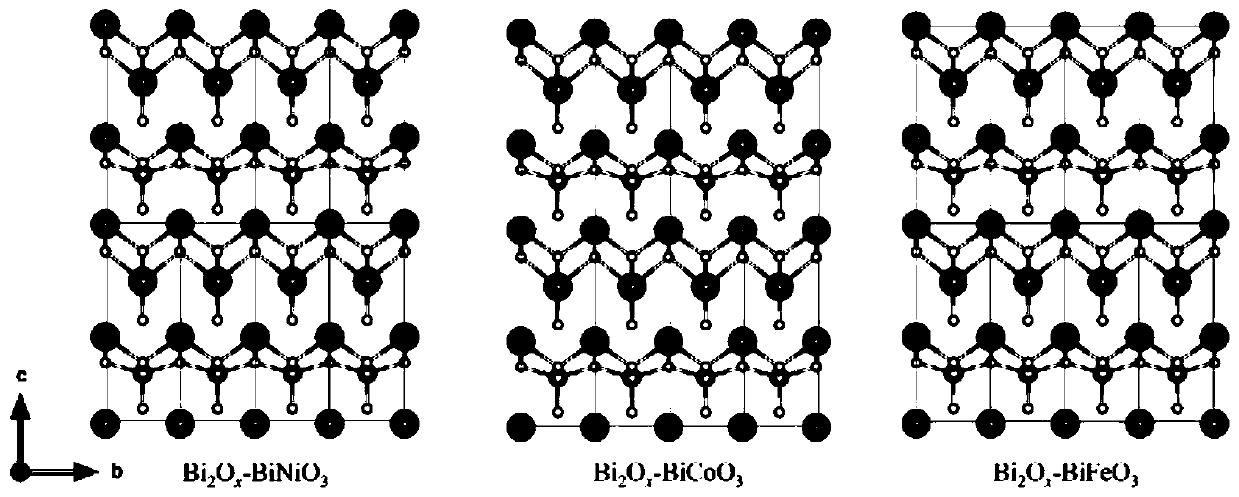

[0075] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 (0) was added 7 mL of ethylene glycol methyl ether (EGME). Then add cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) or nickel nitrate hexahydrate (Ni(NO 3 ) 3 ·6H 2 O). The preparation chemical formula is: Bi 2 o x -BiCoO 3 and Bi 2 o x -BiNiO 3 That is, 10 mL of a precursor solution with a molar ratio of Bi and Me of 3:1 and a molar concentration of 0.25 M. Spin-coat thin films on single crystal substrates. Preheat the substrate on a heating plate at 90°C for 2 minutes, quickly transfer it to a spin coater, use a pipette gun to absorb an appropriate amount of precursor solution and add it drop by drop on the substrate to fully cover the surface of the substrate, and spin coat at a speed of 5000rpm for 30s; Move the substrate to a 90°C heating plate to dry for 10 minutes; rapidly heat to 270°C and bake for 4 minutes; finally move it into an annealing furnace to rapidly raise the temperature, and anneal at ...

Embodiment 2

[0078] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 (0) was added 7 mL of ethylene glycol methyl ether (EGME). Then add cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) the preparation chemical formula is: Bi 2 o x -BiCoO 3 , 10 mL of a precursor solution with a molar concentration of 0.4 M. Spin-coat thin films on single crystal substrates. Preheat the substrate on a 90°C heating plate for 2 minutes, quickly transfer it to a spin coater, use a pipette gun to absorb an appropriate amount of precursor solution and add it drop by drop on the substrate to fully cover the surface of the substrate, and spin coat at 4000rpm for 30s; Move the substrate to a heating plate at 90°C to dry for 10 minutes; quickly heat to 270°C and bake for 4 minutes; finally divide the prepared substrates into three groups and anneal at 500°C, 560°C, and 600°C for 30 minutes respectively; ferroelectric multifunctional thin films.

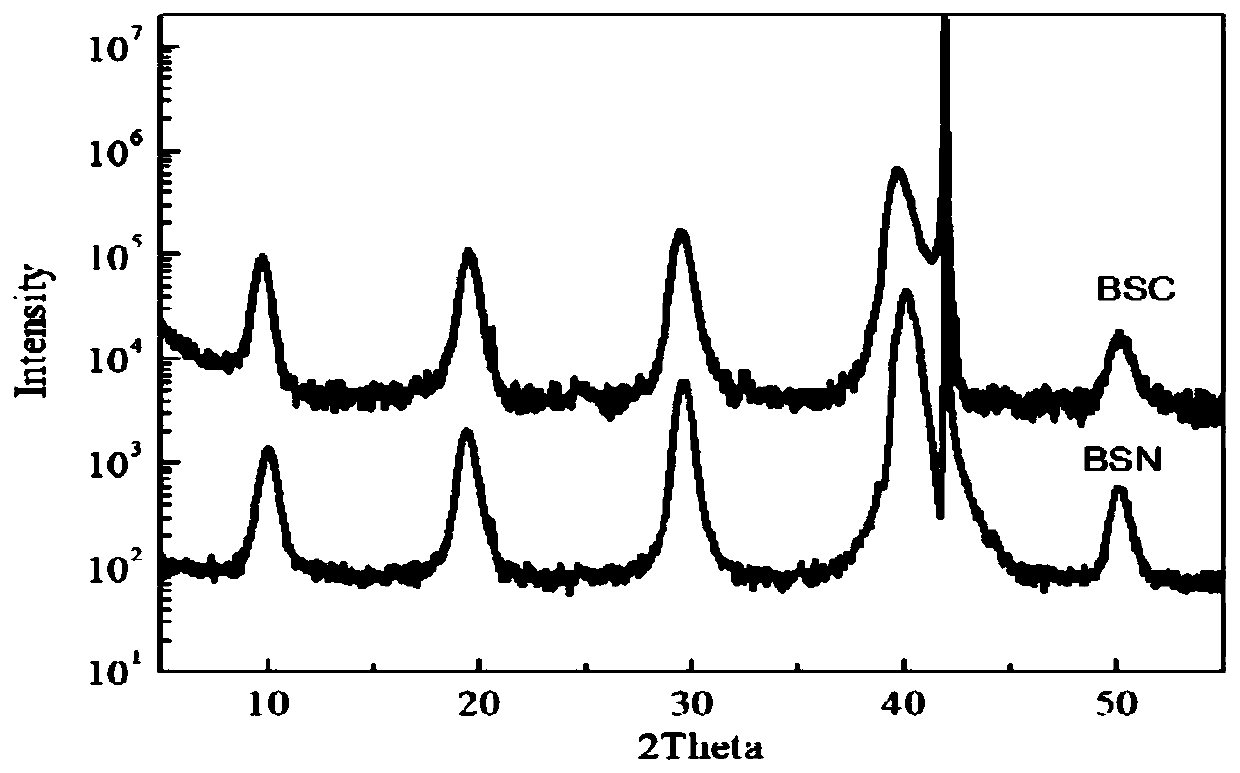

[0079] The prepared thin film is subjected to XRD analysi...

Embodiment 3

[0081] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 (0) was added 7 mL of ethylene glycol methyl ether (EGME). Then add cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) the preparation chemical formula is: Bi 2 o x -BiCoO 3, 10 mL of a precursor solution with a molar concentration of 0.25 M. Spin-coat thin films on single crystal substrates. Preheat the substrate on a heating plate at 90°C for 2 minutes, quickly transfer it to a spin coater, use a pipette gun to absorb an appropriate amount of precursor solution and add it drop by drop on the substrate to fully cover the surface of the substrate, and spin coat at a speed of 5000rpm for 30s; Move the substrate to a heating plate at 90°C to dry for 10 minutes; quickly heat to 270°C and bake for 4 minutes; finally divide the prepared substrates into three groups, and anneal at 500°C for 20 minutes; obtain ferroelectric multifunctional film. The ferroelectric properties of the film were analyzed.

[0082] as attache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com