Latent epoxy resin curing agent and preparation method and application thereof

An epoxy resin curing and epoxy resin technology, which is used in the field of epoxy resin latent curing agent and epoxy resin composition preparation, can solve the problems of poor epoxy resin compatibility, high dissociation temperature and high post-curing temperature. , to achieve the effect of good compatibility and long pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of latent epoxy curing agent:

[0059] 1. In N 2 protected by AlCl 3 As a catalyst, react benzenethiol with a molar ratio of 1:0.9 and acetic acid at 120°C for 4.5h to obtain benzenethiol acetate, in which AlCl 3 The consumption of benzene thiol is 0.5%wt.

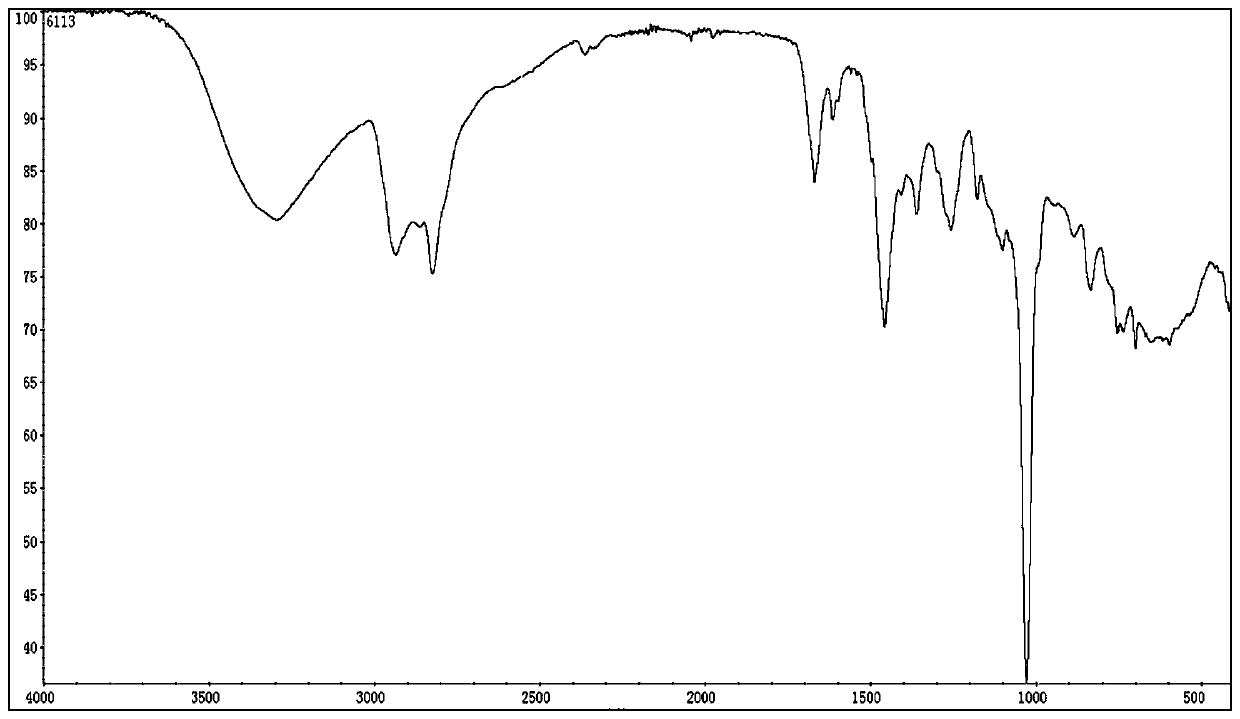

[0060] 2. Add 0.9 mol of WANALINK6200 to 1 mol of the obtained benzenethiol acetate, stir well, then raise the temperature to 80°C, add 1.95 mol of acetaldehyde dropwise, and react for 3.5 hours to obtain a latent epoxy resin curing agent. Its infrared spectrum is as figure 1 As shown, it can be seen from the FT-IR infrared spectrum that 1490cm -1 -SCOCH in the curing agent of the present invention 3 Absorption peak at 1050cm -1 for -CH(CH 3 )-absorption peak, 3300cm -1 It is the absorption peak of tertiary amine, indicating that phenolic benzene thiol ester has been generated.

[0061] Preparation of epoxy resin composition:

[0062] Preparation of component A: Mix 75g of bisphenol F diglycidy...

Embodiment 2

[0068] Preparation of latent epoxy curing agent:

[0069] 1. In N 2 protected by FeCl 3 As a catalyst, react benzenethiol with propionic acid at a molar ratio of 1:1.1 for 3.5 hours at 150°C to obtain benzenethiol propionate, in which FeCl 3 The consumption is 3wt% of benzene thiol.

[0070] 2. Add 1.1 mol of UNILINK7100 to 1 mol of the obtained benzenethiol propionate, stir well and heat up to 95°C, add 2.05 mol of benzaldehyde dropwise, and react for 3.5 hours to obtain a latent epoxy resin curing agent.

[0071] Preparation of epoxy resin composition:

[0072] Preparation of component A: Mix 65g of bisphenol A glycidyl ether E-51 (DOW brand is DER331, epoxy value 0.51) with 14g of 1,6-hexanediol diglycidyl ether and 21g of BYK066N defoamer stand still.

[0073] Preparation of component B: 75g of the latent curing agent prepared in this example and 25g of tin tetrachloride were added into the reaction kettle, mixed evenly, and left to stand.

[0074] Mix component A an...

Embodiment 3

[0078] Preparation of latent epoxy curing agent:

[0079] 1. In N 2 protected under CH 3 COONa is a catalyst, reacting benzenethiol and benzoic acid with a molar ratio of 1:1 at 130°C for 4h to obtain benzoic acid benzenethiol ester, wherein CH 3 COONa consumption is 2wt% of benzene thiol.

[0080] 2. Add 1 mol of UNILINK4102 to 1 mol of the obtained benzenethiol benzoate, stir well and heat up to 85°C, add 2 mol of benzaldehyde dropwise, and react for 3 hours to obtain a latent epoxy resin curing agent.

[0081] Preparation of epoxy resin composition:

[0082] Preparation of component A: Mix 70g of bisphenol A glycidyl ether E-51 (DOW brand is DER331, epoxy value 0.51) with 10g of butyl glycidyl ether and 20g of BYK6800 defoamer, and then let stand.

[0083] Preparation of component B: Add 80 g of the latent curing agent prepared in this example and 20 g of boron trifluoride into the reaction kettle, mix them evenly, and let stand.

[0084] Mix components A and B evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com