Special pickling cleaning agent for reverse osmosis and preparation method thereof

A special acid and reverse osmosis technology, applied in reverse osmosis, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc. Incomplete pollution and other problems, to achieve significant removal effect, increased synergistic effect, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

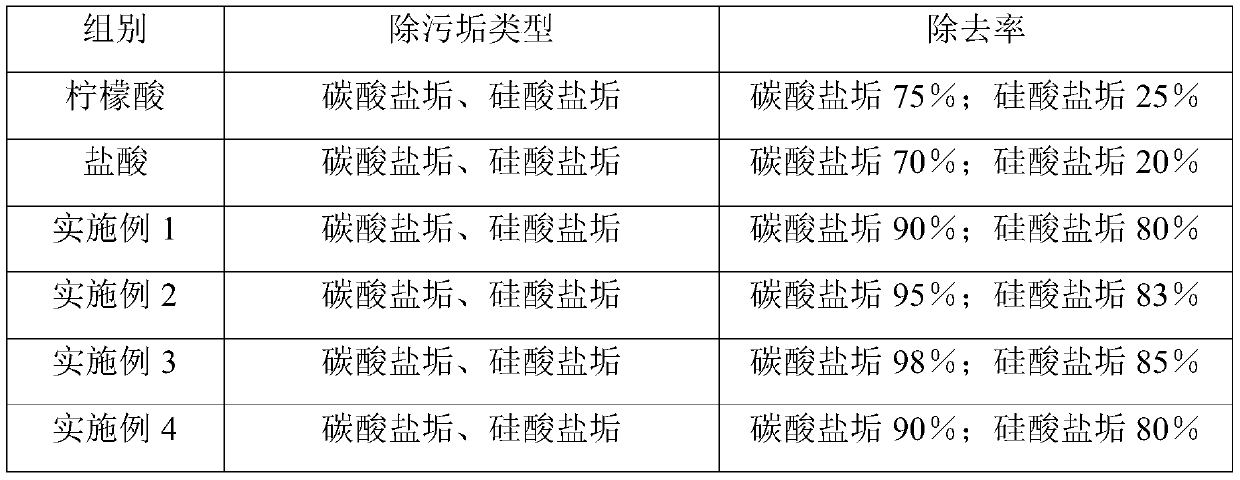

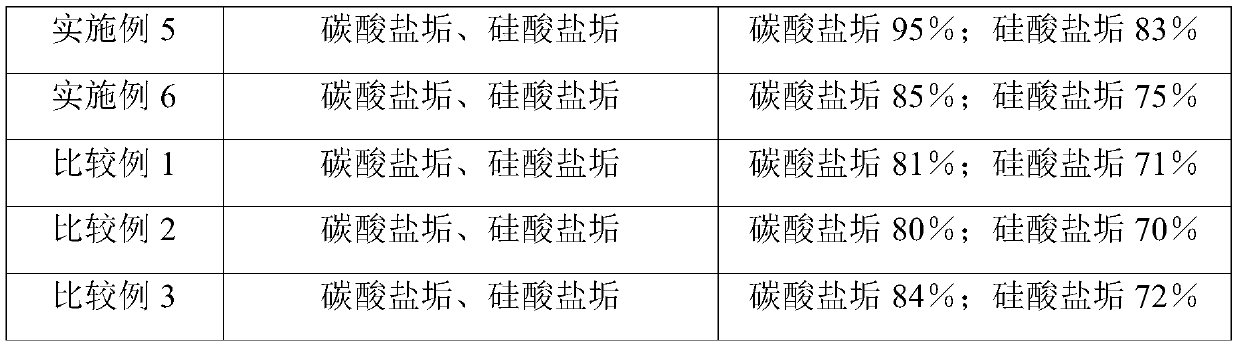

Examples

Embodiment 1

[0035] The specific preparation process of the special pickling cleaning agent for reverse osmosis is as follows:

[0036] 1. Dosing each raw material according to the following parts by mass:

[0037] 30 parts of organic acid (10 parts of thiocarboxylic acid, 10 parts of hydrofluoric acid, 10 parts of ethylenediaminetetraacetic acid), 3 parts of ethylenediaminetetraacetic acid salt, 3 parts of isothiazolinone, 5 parts of sodium chloride, 1 Parts of polyoxyethylene ether and 58 parts of water;

[0038] 2. Mix organic acid, ethylenediamine tetraacetate, isothiazolinone, and sodium chloride and add it to a variable-speed mixer, and stir for 20 minutes at a temperature of 20°C to obtain a mixture A;

[0039] 3. Mix mixture A and polyoxyethylene ether into a variable speed mixer at a temperature of 20°C and continue stirring for 30 minutes to obtain the invented acidic cleaning agent for reverse osmosis;

[0040] 4. Packaging, testing, and forming products for sale.

Embodiment 2

[0042] The specific preparation process of the special pickling cleaning agent for reverse osmosis is as follows:

[0043] 1. Dosing each raw material according to the following parts by mass:

[0044] 50 parts of organic acid (20 parts of sulfamic acid, 20 parts of glycolic acid, 10 parts of sulfinic acid), 6 parts of diethylene triamine pentacarboxylate, 5 parts of isothiazolinone, 12 parts of sodium nitrate, 4 parts of polyoxygen Ethylene and 23 parts of water;

[0045] 2. Mix the organic acid, ethylene triamine pentacarboxylate, isothiazolinone, and sodium nitrate into a variable-speed mixer, and stir at 60°C for 10 minutes to obtain mixture A;

[0046] 3. Dissolve the mixture A and polyoxyethylene and mix them into a variable-speed mixer at a temperature of 55°C, and continue to stir for 10 minutes to obtain the invented acidic cleaning agent for reverse osmosis;

[0047] 4. Packaging, testing, and forming products for sale.

Embodiment 3

[0049] The specific preparation process of the special pickling cleaning agent for reverse osmosis is as follows:

[0050] 1. Dosing each raw material according to the following parts by mass:

[0051]36 parts of organic acid (15 parts of carboxylic acid, 11 parts of sulfonic acid, 10 parts of oxalic acid), 5 parts of polyacrylic acid, 4 parts of formaldehyde solution (the concentration of formaldehyde solution is 30wt%), 10 parts of potassium chloride, 3 parts of polyoxyethylene Ether and 42 parts of water;

[0052] 2. Mix organic acid, polyacrylic acid, formaldehyde solution and potassium chloride and add it to a variable speed mixer, and stir at 40°C for 15 minutes to obtain mixture A;

[0053] 3. Dissolved the mixture A and polyoxyethylene, mixed them into a variable-speed mixer at a temperature of 40°C, and continued to stir for 20 minutes to obtain the invented acidic cleaning agent for reverse osmosis;

[0054] 4. Packaging, testing, forming products for sale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com