Preparation method of hexagonal boron nitride nanospheres with layered cavitation structure

A technology of hexagonal boron nitride and nanospheres, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high risk factor, poor uniformity, and large cavitation center volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

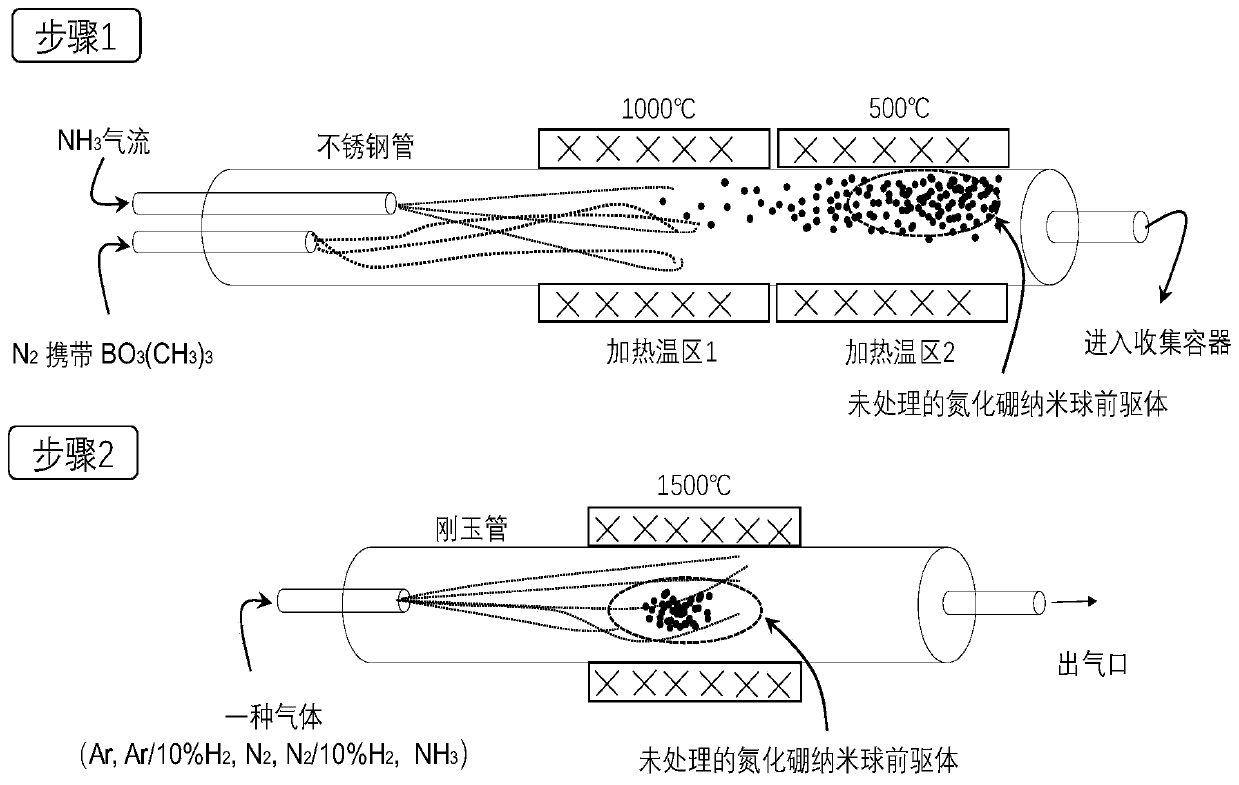

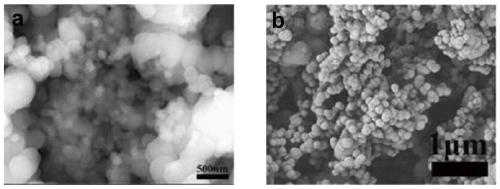

[0030] (1) Using trimethyl borate as the boron source and ammonia as the nitrogen source, since trimethyl borate is volatile, trimethyl borate is carried into the reaction temperature zone by nitrogen bubbling to synthesize hexagonal spherical boron nitride. First, ammonia gas is passed into the stainless steel tube at a flow rate of 400mL / min. The temperature of the first tube furnace is raised to 1000°C at a rate of 5°C / min, while the temperature of the second tube furnace is raised to 500°C at a rate of 5°C / min. ℃, and continue scrubbing for 30 minutes after reaching the temperature. Then in the form of nitrogen bubbles with a flow rate of 400mL / min N 2 The volatile B(OCH 3) 3 Bring into the stainless steel pipe with NH 3 The reaction is carried out to obtain a boron nitride nanosphere precursor.

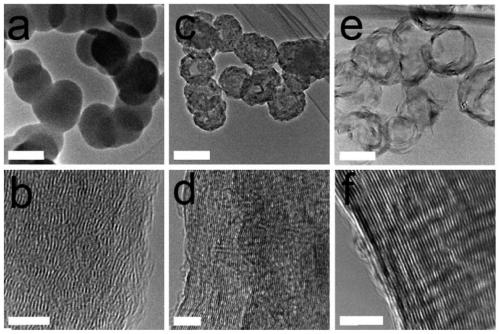

[0031] (2) Place the boron nitride nanosphere precursor obtained in step (1) in the corundum ark, then put it into the alumina tube, feed hydrogen-nitrogen mixed gas, the flo...

Embodiment 2

[0033] Change the hydrogen-nitrogen mixed gas introduced in step (2) in Example 1 into hydrogen-argon mixed gas (hydrogen volume 10%), and other operations are the same as in Example 1 to obtain hydrogen-argon mixed gas for secondary treatment. Boron nitride nanospheres.

Embodiment 3

[0035] The mixed gas of hydrogen and nitrogen introduced in step (2) in Example 1 was changed to nitrogen, and the other operations were the same as in Example 1 to obtain boron nitride nanospheres treated with nitrogen for the second time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com