Preparation method of high-purity silicon carbide powder for single crystal growth

A technology of high-purity silicon carbide powder and high-purity graphite powder, which is applied in the fields of semiconductor materials and power electronics industry, can solve the problems of single phase of synthetic powder, influence the purity of synthetic SiC powder, increase the cost of powder preparation, etc. The effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high-purity β-SiC powder synthesis process for high-purity semi-insulating silicon carbide single crystal growth:

[0036] Using high-purity graphite powder (purity>99.999%) and high-purity Si powder (purity>99.999%) as raw materials, polytetrafluoroethylene as additive, high-purity graphite powder and high-purity Si powder are uniformly mixed according to the molar ratio of 1:1.02 , polytetrafluoroethylene and mixed raw materials are added according to the mass ratio of 1:100. The proportioned raw materials are placed in a high-purity graphite crucible (purity>99.9995%), and the graphite crucible and graphite insulation are placed in an intermediate frequency induction heating furnace for heating. First, before heating, inject high-purity H into the furnace cavity 2 (purity > 99.999%) to 800mbar, keep for 10 minutes, then vacuum to 5×10 -6 mbar, followed by reinjection of high-purity H 2 to 800mbar, keep it for 10 minutes, and then evacuate to 5×10 -6 mbar, recip...

Embodiment 2

[0038] A high-purity α-SiC powder synthesis process for high-purity semi-insulating silicon carbide single crystal growth:

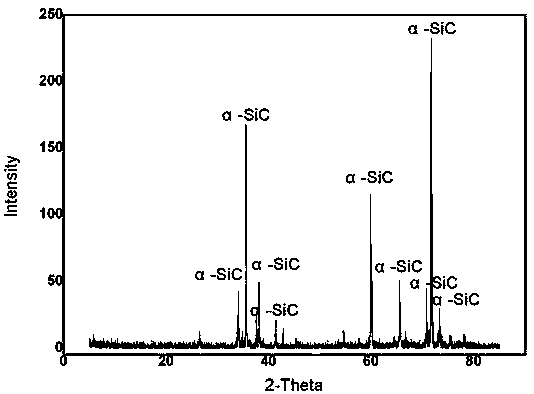

[0039] The process of synthesizing high-purity β-SiC in Example 1 was repeated to synthesize high-purity β-SiC powder. Subsequently, at 1200°C, the high-purity H 2 Inject into the furnace cavity, keep the pressure at 800mbar, keep it for 1h, then put Ar, H 2 And HCl is continuously injected into the furnace cavity according to the flow ratio of 100:1:1, so that the pressure of the furnace cavity is maintained at 800mbar, and the temperature is rapidly raised to 1900°C-2100°C. This temperature range is the range where β-SiC begins to transform into α-SiC. Here In the interval, as the temperature increases, the particle size of the transformed α-SiC will increase accordingly. Therefore, the temperature value can be preset according to the demand and kept for 10 hours. Then between Ar and H 2 The protection is lowered to room temperature, and the synthe...

Embodiment 3

[0042] A high-purity β-SiC powder synthesis process for high-purity semi-insulating silicon carbide single crystal growth:

[0043] Using high-purity graphite powder (purity>99.999%) and high-purity Si powder (purity>99.999%) as raw materials, polytetrafluoroethylene as additive, high-purity graphite powder and high-purity Si powder are uniformly mixed according to the molar ratio of 1:1.1 , polytetrafluoroethylene and mixed raw materials are added according to the mass ratio of 1:110. The proportioned raw materials are placed in a high-purity graphite crucible (purity>99.9995%), and the graphite crucible and graphite insulation are placed in an intermediate frequency induction heating furnace for heating. First, before heating, inject high-purity H into the furnace cavity 2 (purity > 99.999%) to 750mbar, keep for 15 minutes, then vacuum to 6×10 -6 mbar, followed by reinjection of high-purity H 2 to 750mbar, keep it for 15 minutes, and then evacuate to 6×10 -6 mbar, recipr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com