Fumed silica tail gas treatment system and treatment method thereof

A gas-phase white carbon black and tail gas treatment technology, applied in chemical instruments and methods, chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve the problems of large environmental pollution, unstable by-products, etc., and achieve high economic value-added, flexible sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

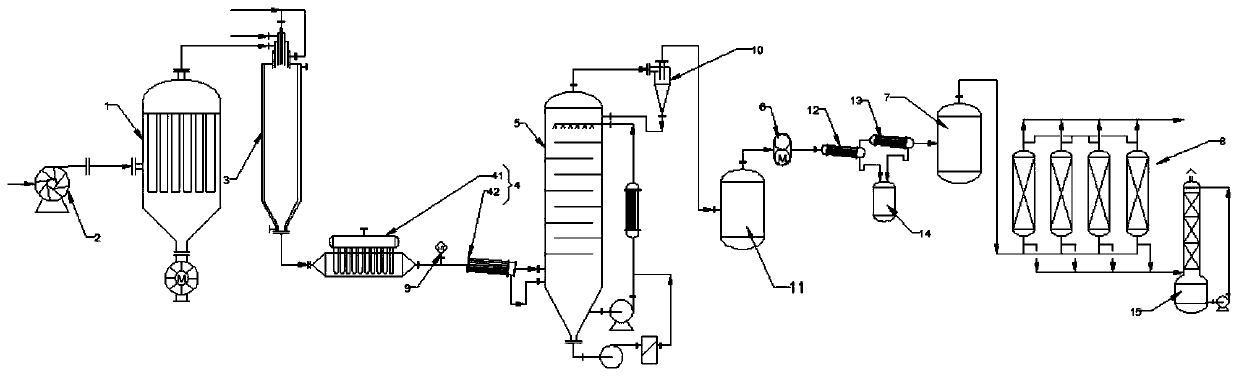

[0035] This embodiment, as the basic embodiment of the present invention, discloses a gas phase white carbon black tail gas treatment system, the specific structure is as follows figure 1 As shown, along the flow direction of the air flow, there are sequentially connected a booster fan 2, a bag filter 1, a synthesis furnace 3, a cooling device 4, a drying tower 5, a gas compressor 6, a high-pressure buffer tank 7 and a pressure swing adsorption tower group 8 , wherein the upper and lower sides of the bag filter 1 are respectively provided with an exhaust port and a solid material discharge port, and its side wall is provided with an air inlet, which is connected to the booster fan 2, and the solid material discharge port is connected to Corresponding dust recovery equipment;

[0036]The upper part of the synthesis furnace 3 is provided with a plurality of feed ports, and each feed port is airtightly connected with the corresponding gas source, and the bottom thereof is a disch...

Embodiment approach 2

[0041] This embodiment, as another preferred embodiment of the present invention, discloses a gas phase white carbon black tail gas treatment method, which includes the following steps:

[0042] S1. Incorporate the exhaust gas into the booster fan. After increasing the fan booster, the exhaust gas is passed into the bag filter after being pressurized. The filter bag in the bag filter is recommended to be made of PTFE-coated Flumes needle felt. filter bags;

[0043] S2, the tail gas after the dedusting of step S1 is passed into the synthesis furnace, and chlorine and hydrogen are passed into the synthesis furnace simultaneously, according to the content change of chlorine in the tail gas, under standard conditions, the volume ratio of the hydrogen and chlorine that is passed into is 1.05:1, and the above-mentioned gases are fully mixed and then ignited in the synthesis furnace to make it continue to burn. After full combustion, all the chlorine in the tail gas and the chlorine ...

Embodiment approach 3

[0047] Present embodiment is another preferred embodiment of the present invention, and it discloses a kind of gas-phase white carbon black tail gas treatment method, and it comprises the following steps:

[0048] S1. Incorporate the exhaust gas into the booster fan. After increasing the fan booster, the exhaust gas is passed into the bag filter after being pressurized. The filter bag in the bag filter is recommended to be made of PTFE-coated Flumes needle felt. filter bags;

[0049] S2, the tail gas after the dedusting of step S1 is passed into the synthesis furnace, and chlorine and hydrogen are passed into the synthesis furnace simultaneously, according to the content change of chlorine in the tail gas, under standard conditions, the volume ratio of the hydrogen and chlorine that is passed into is 2:1, and the above gas is fully mixed and then ignited in the synthesis furnace to make it continue to burn. After full combustion, all the chlorine in the tail gas and the chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com