Unsaturated resin or vinyl resin composition and application thereof to composite material

A vinyl resin and unsaturated technology, which is applied in the field of composite material preparation and resin synthesis, can solve the problems of harsh and complex production process, environmental protection and performance problems, poor toughness of composite materials, etc., and achieve high viscosity adjustability and low product cost Adjustable, excellent weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

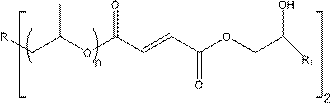

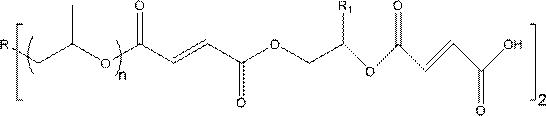

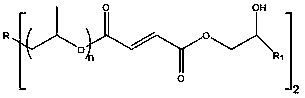

[0034] Add 100 kg of maleic anhydride hydroxyl-terminated polyester (Nantong Matech Company, MT-2408, f=2, R and R1 are alkanes with 4 carbon atoms, n=6, hydroxyl value=140mgKOH / g) to the reactor and heated up to 140°C. After the temperature stabilized, immediately add 25 kg of maleic anhydride and keep it warm for 0.5h to obtain an oligomer with a double bond at the end: maleic anhydride-terminated unsaturated polyester diol, The general structural formula is as follows:

[0035]

[0036] According to the following formula for resin configuration:

[0037] Oligomers with double bonds at the end: 100 kg

[0038] Styrene 60 kg

[0039] Benzoyl peroxide 0.8kg

[0040] tert-butyl perbenzoate 1.5 kg

[0041] Cobalt naphthenate 0.5 kg

[0042] Stearic acid 1 kg

[0044] Pour the configured resin glue into the resin tank of the pultrusion equipment, and through the pultrusion process, the glass fiber will be filled with resin through the resin t...

Embodiment 2

[0046]50 kg of polyoxyethylene ether trihydric alcohols and tetrahydric alcohols with a hydroxyl value of 560 mgKOH / g, a saturated polyol with a functionality of f=3.5 and 50 kg of unsaturated polyols with a hydroxyl value of 112 mgKOH / g Add polybutadiene into the reaction kettle and raise the temperature to 90°C. After the temperature stabilizes, add 100 kg of methyltetrahydrophthalic anhydride immediately and keep it warm for 2 hours to obtain an oligomer with a double bond at the end, and proceed according to the following formula Resin configuration:

[0047] Oligomers with double bonds at the end: 100 kg

[0048] Styrene 50 kg

[0049] Polypropylene glycol diacrylate 150 kg

[0050] 6 kg methyl ethyl ketone peroxide

[0051] Cobalt isooctanoate 0.2 kg

[0052] Pour the configured resin glue into the closed resin tank of the vacuum infusion equipment, and through the resin vacuum introduction process, the resin is pumped through the vacuum pump and the closed plastic t...

Embodiment 3

[0054] Add 100 kg of saturated polyols with a hydroxyl value of 400 mgKOH / g and a functionality f=3 composed of polypropylene oxide ether diols, triols and tetraols into the reactor, and keep the ambient temperature;

[0055] Mix 174 kg of toluene diisocyanate (2000 mol of isocyanate groups) and 116 kg of hydroxyethyl acrylate (1000 mol of hydroxyl groups) and heat up to 60°C for 3 hours to obtain an unsaturated urethane-type blocking agent;

[0056] Mix 100 kg of the above-mentioned saturated polyol with the above-mentioned 207 kg of end-capping agent at ambient temperature and react at this temperature for 4 hours to obtain an oligomer with a double bond at the end, and configure the resin according to the following formula:

[0057] Oligomers with double bonds at the end: 100 kg

[0058] Hydroxypropyl methacrylate 50 kg

[0059] Tripropylene glycol diacrylate 50 kg

[0060] Azobisisobutyronitrile 0.2 kg

[0061] Di-tert-butyl peroxide 0.8 kg

[0062] Organic tin 0.2 kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com