Environment-friendly odorless foaming sole material and method for preparing sole

A sole material and environmental protection technology, applied in the field of polyurethane elasticity, can solve the problems of poor mechanical properties of polyurethane materials, not conforming to green environmental protection, unfavorable to human health, etc., and achieve good economic benefits, good biocompatibility, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

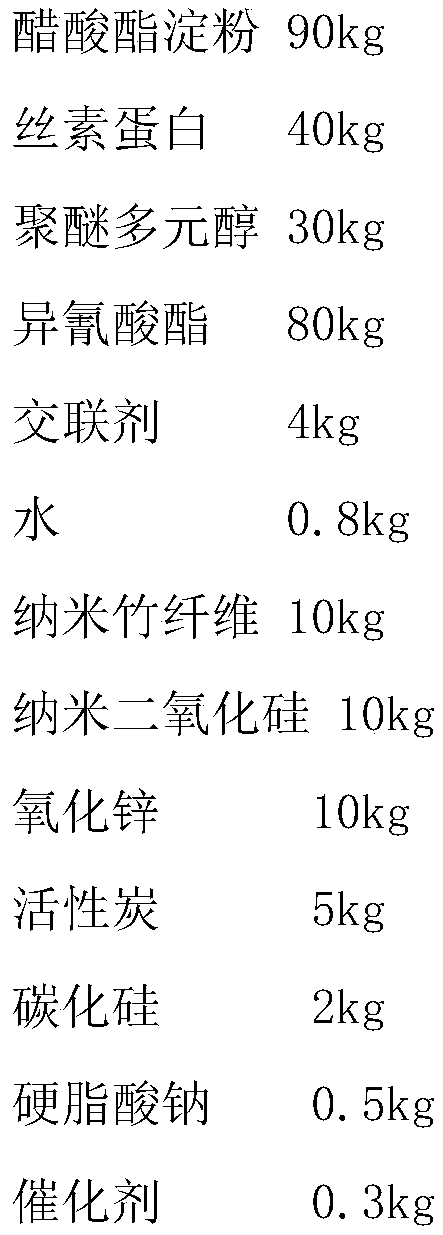

[0026] An environmentally friendly and odorless foam sole material is made from the following weights:

[0027]

[0028] Wherein the cross-linking agent is a mixture of glycerin, diethanolamine and triethanolamine, glycerol by mass ratio: diethanolamine: triethanolamine=1:1:1;

[0029] Wherein the catalyst is a mixture of triethylenediamine and triethanolamine, which is triethylenediamine in mass ratio: triethanolamine=2:1;

[0030] Wherein the isocyanate is 4,4-diphenylmethane diisocyanate.

[0031] A kind of environmental protection tasteless foaming sole of the present invention, its preparation method is carried out according to the following steps:

[0032] Step 1, according to the above ratio, put starch acetate, silk fibroin, sodium stearate, foaming agent and catalyst into reaction kettle 1 at room temperature, and stir for 2 hours to obtain mixture A;

[0033] Step 2: According to the above ratio, put the polyether polyol into the reaction kettle 2 at room temper...

Embodiment 2

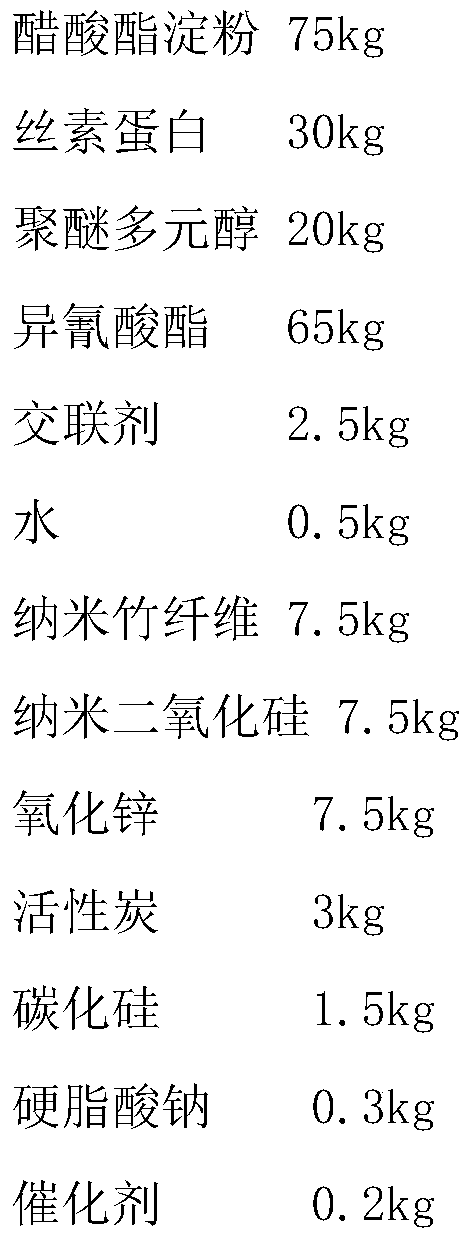

[0036] An environmentally friendly and odorless foam sole material is made from the following weights:

[0037]

[0038] Wherein the cross-linking agent is a mixture of glycerin, diethanolamine and triethanolamine, glycerol by mass ratio: triethanolamine=1:1;

[0039] Wherein the catalyst is triethylenediamine;

[0040] Wherein the isocyanate is 2,4-diphenylmethane diisocyanate.

[0041] A kind of environmental protection tasteless foaming sole of the present invention, its preparation method is carried out according to the following steps:

[0042] Step 1: Put starch acetate, silk fibroin, sodium stearate, foaming agent and catalyst into reaction kettle 1 at room temperature according to the above ratio, and stir for 1 hour to obtain mixture A;

[0043] Step 2: According to the above ratio, put the polyether polyol into the reaction kettle 2 at normal temperature, stir and heat up to 120°C, vacuumize to -0.1MPa, dehydrate and degas for 3.5 hours, then cool down to 60°C, ...

Embodiment 3

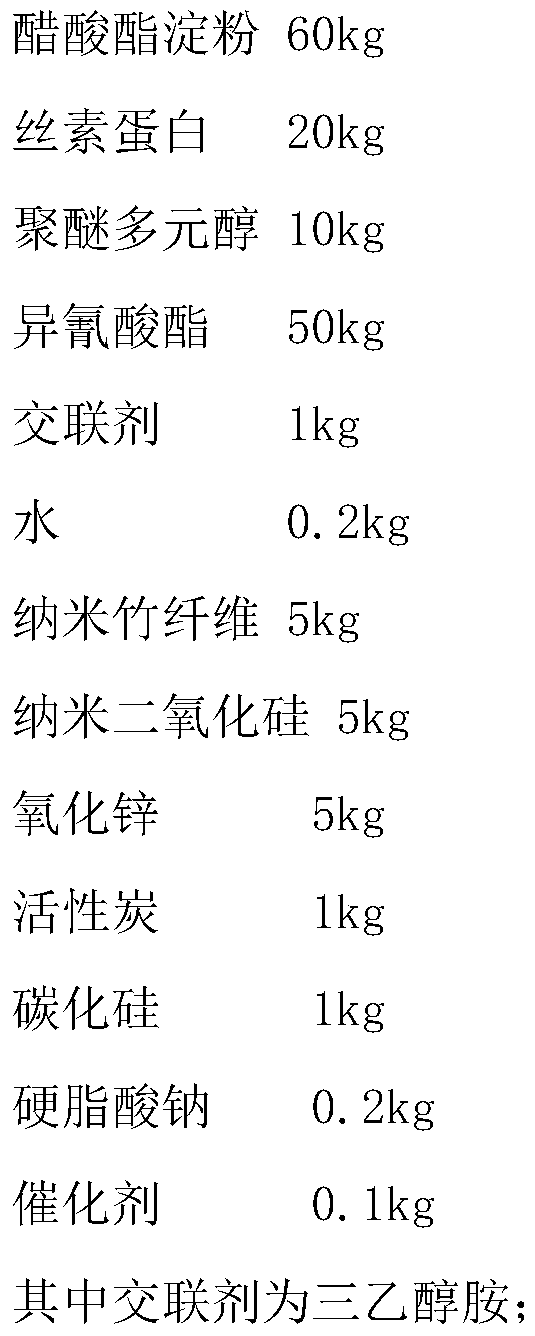

[0046] An environmentally friendly and odorless foam sole material is made from the following weights:

[0047]

[0048] Wherein the catalyst is a mixture of triethylenediamine and triethanolamine, which is triethylenediamine in mass ratio: triethanolamine=1:1;

[0049] The isocyanate is a mixture of 2,4-diphenylmethane diisocyanate and 4,4-diphenylmethane diisocyanate, and the mass ratio of the two is 2:1.

[0050] A kind of environmental protection tasteless foaming sole of the present invention, its preparation method is carried out according to the following steps:

[0051] Step 1: Put acetate starch, silk fibroin, sodium stearate, foaming agent and catalyst into reaction kettle 1 at room temperature according to the above-mentioned ratio, and stir for 1.5 hours to obtain mixture A;

[0052] Step 2: According to the above ratio, put the polyether polyol into the reaction kettle 2 at normal temperature, stir and heat up to 120°C, vacuumize to -0.1MPa, dehydrate and dega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com