Preparation method of composite heavy metal contaminated site improver

A technology of heavy metals and modifiers, applied in chemical instruments and methods, fertilizer mixtures, fertilizers made of biological waste, etc., can solve the problems of poor passivation performance and poor durability of modifiers, and achieve improved passivation performance and passivation chemical stability, low cost, and the effect of enhancing passivation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

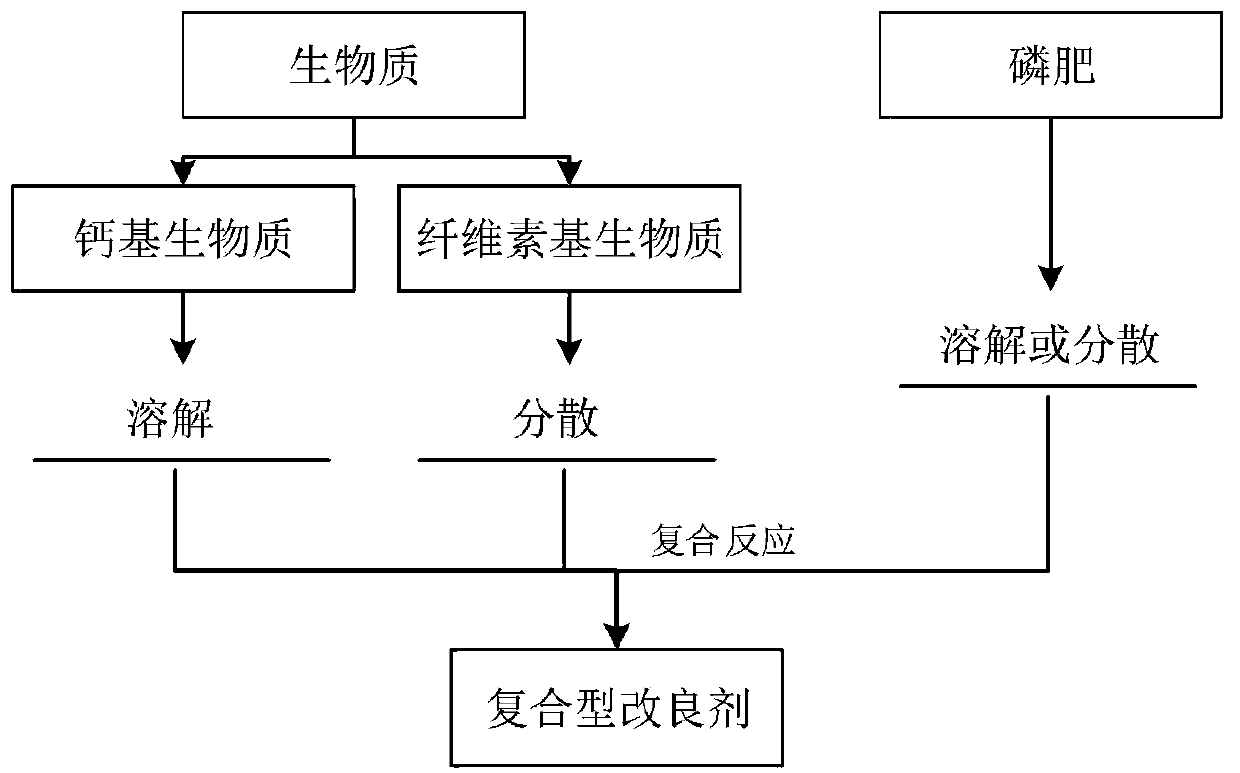

Method used

Image

Examples

Embodiment 1

[0038] Take fresh rice straw, wash it with water, dry to constant weight, crush, and sieve, take 260-74μm rice straw, use egg shell as calcium-based biomass, grind, sieve, take 74μm or more for pretreatment, and use 0.5 The nitric acid solution of mol / L is the solvent, the weight ratio of rice straw powder and egg shell powder is 2:1, the mixed solid weight and solvent volume ratio is 1:3kg / L, and at room temperature, the premixing time is 2h at 150rpm. Calcium phosphate as the main component and calcium dihydrogen phosphate as the main component of the phosphorus source of the mixed phosphate fertilizer, the mass ratio of calcium phosphate and calcium dihydrogen phosphate is 1:1, the particle size of calcium phosphate is more than 74 μm, and 1mol / L phosphoric acid The solution is a solvent, and the solid-to-liquid ratio is 1:5kg / L for mixing, dissolving and dispersing. The reaction temperature is 50°C and 200rpm for 4h. The mixed solution of the pretreated phosphate fertilize...

Embodiment 2

[0042] Take commercially available rice husk charcoal, grind and sieve, take 149 μm rice husk charcoal, use N,N-dimethylformamide solution as solvent, and use calcium hydrogen phosphate as the main component and mixed phosphate fertilizer with calcium dihydrogen phosphate as the main component As a phosphorus source, the mass ratio of calcium hydrogen phosphate to calcium dihydrogen phosphate is 2:1, the weight ratio of rice husk charcoal to phosphate fertilizer is 3:1, and 0.1mol / L nitric acid-sulfuric acid solution and N,N-dimethyl Dimethylformamide mixed solution is used as solvent, the volume ratio of 0.1mol / L nitric acid-sulfuric acid solution to N,N-dimethylformamide solution is 1:1, and the volume ratio of mixed solid weight to solvent is 1:10 for mixing and dissolving , the pretreatment temperature was room temperature, and the reaction was performed at 200rpm for 2h. Then use shell powder as calcium-based biomass, the particle size of shell powder is more than 74 μm, ...

Embodiment 3

[0046] Take camphor wood chips, rinse with water, dry to constant weight, crush, sieve, take camphor wood chips over 149 μm and 0.1mol / L sodium hydroxide solution at a solid-to-liquid ratio of 1:2, at room temperature, 150rpm Premixing time is 2h. The phosphate fertilizer with calcium dihydrogen phosphate as the main component is the phosphorus source, and the egg shell is used as the calcium-based biomass, crushed and sieved, and the 74 μm or more is used for the experiment. The weight ratio of the phosphate fertilizer and the egg shell is based on Ca: P molar ratio = 1.7 Calculate the proportion, use 0.5mol / L phosphoric acid solution as the solvent, mix and dissolve the mixed solid weight to solvent volume ratio of 1:5kg / L, and react for 1h at the reaction temperature of 30°C and 200rpm. Then the pretreated sawdust solution was gradually added to the mixed system of phosphate fertilizer and egg shell, and the acidity was controlled by adding sodium hydroxide solution dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com