Epitaxy method for growing blue light emitting diode on m-plane gallium nitride substrate

A gallium nitride substrate and light-emitting diode technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of growing GaN thin films and InGaN quantum well In incorporation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

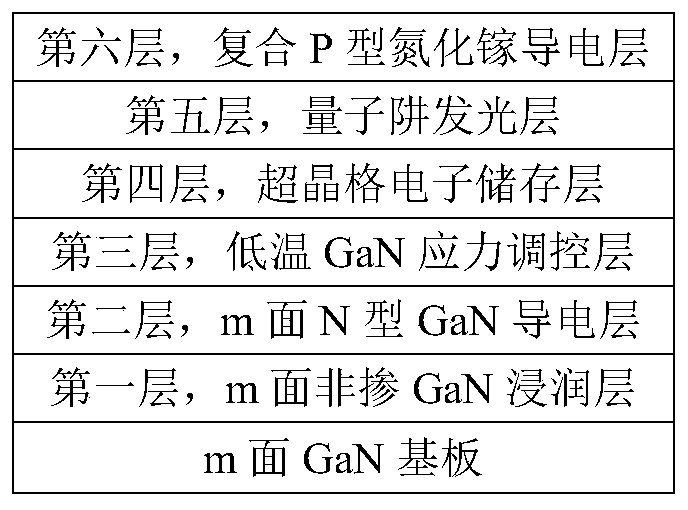

[0034] refer to Figure 1-5 , this embodiment provides a method for growing blue light-emitting diodes on an m-plane gallium nitride substrate, wherein the m-plane gallium nitride substrate is a non-polar self-supporting m-plane with a size of 5mm*10mm and no off-angle prepared by the HVPE method GaN commercial products

[0035] For product specification parameters, please refer to "http: / / shop.nanowin.com.cn / product_center.php".

[0036] The structure of the present invention is as figure 1 ,include:

[0037] S1. Provide an m-plane GaN substrate;

[0038] S2, growing a non-doped GaN homoepitaxial thin film wetting layer on the substrate by metal organic chemical vapor deposition;

[0039] S3. Growing an N-type conductive GaN epitaxial layer on the non-doped GaN thin film at high temperature by metal-organic chemical vapor deposition;

[0040] S4. Growing a gallium nitride stress regulating layer on the N-conductive GaN thin film by metal-organic chemical vapor deposition...

specific Embodiment

[0045] 1) Put the m-plane self-supporting GaN template into the metal organic chemical vapor deposition (MOCVD) equipment.

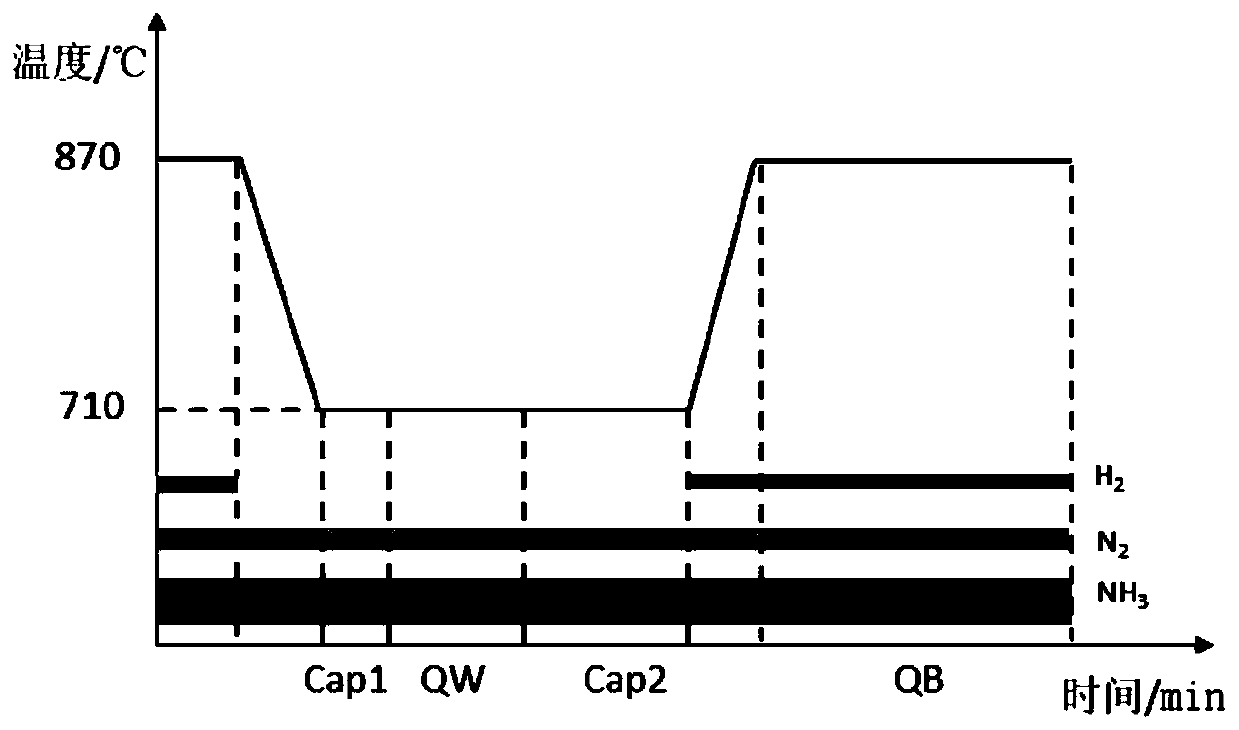

[0046] 2) In order to suppress the decomposition of the GaN surface as the temperature increases, the GaN template is 2 / NH 3 Slowly heat up to 950°C under atmosphere, N 2 / NH 3 The total air flow is controlled at 120-150slm / min, where NH 3 The proportion is 40%-50%, the reaction chamber pressure is 75torr, and the heating rate is 60-80℃ / min.

[0047] 3) Keep the temperature at 950°C and the pressure in the reaction chamber at 75torr, reduce the amount of N2 feeding, and start feeding H 2 , control N 2 :H 2 :NH 3 The ratio is 25:25:50, the total air flow is 120-150slm / min, and the step time is 30s.

[0048] 4) Keep the above growth conditions unchanged, pass through trimethylgallium TMGa to provide Ga source, and start to grow the GaN wetting layer, the growth rate is controlled at 15-20nm / min, and the growth thickness is 200nm.

[0049] 5) Rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com