Method for preparing magnetic biomass charcoal from potamogeton crispus and application thereof

A magnetic biomass charcoal and biomass charcoal technology, applied in the field of water treatment, can solve the problems of reduced pollutant removal effect, small diameter of biomass charcoal particles, unfavorable regeneration and reuse, etc. The effect of content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples.

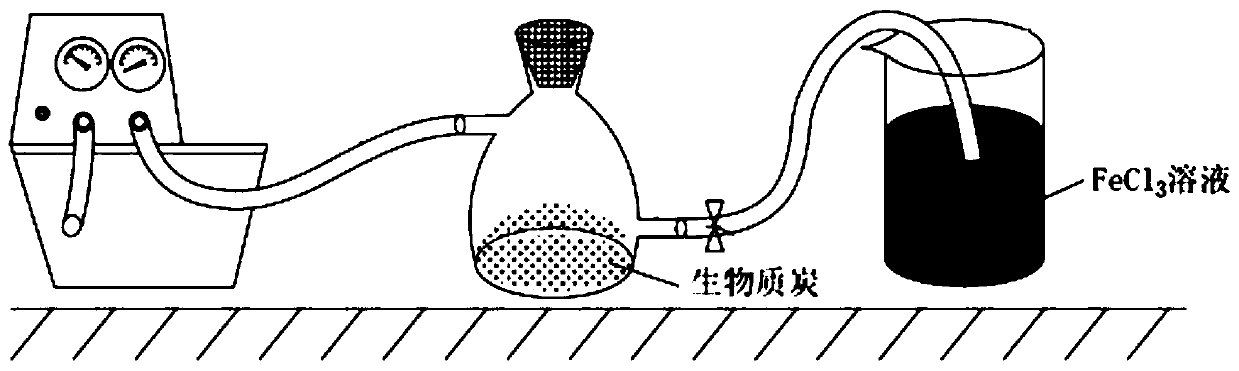

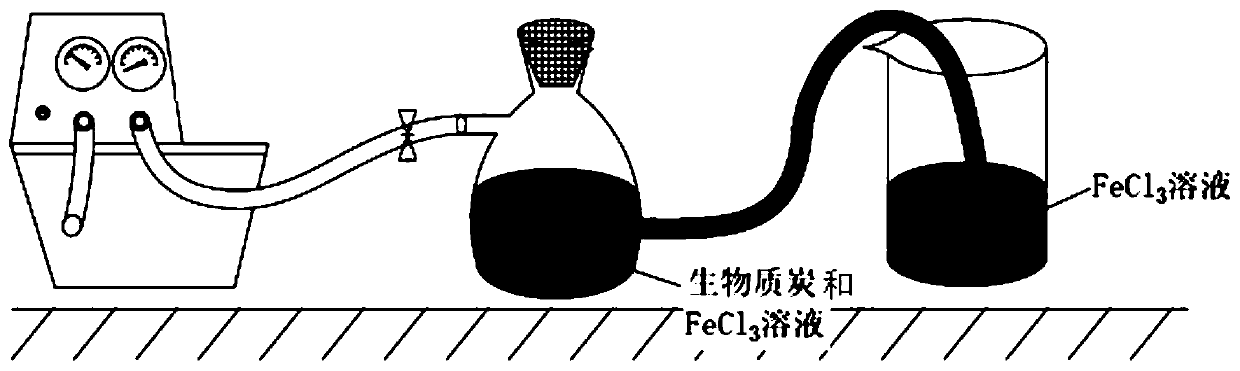

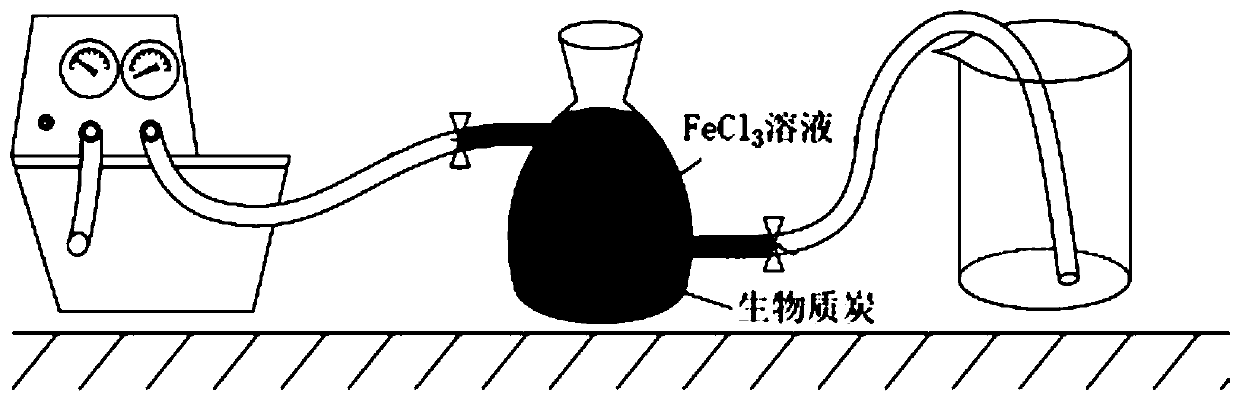

[0029] The invention provides a method for preparing magnetic biomass charcoal from Paleopsis chinensis, comprising the following steps:

[0030] Step 1. Selecting the aquatic plant Smilax as raw material, and preparing the Smilax biochar by anoxic pyrolysis method.

[0031] Wash the weeds, dry or dry them, cut them into pieces, and put them in a pulverizer to pulverize them into powder. Take a certain amount of Scutellaria powder and put it into the crucible, compact and fill the crucible, cover the crucible, and wrap the crucible with aluminum foil to seal it.

[0032] Put the wrapped crucible into a muffle furnace, and pyrolyze it at a constant temperature of 300-500°C for 1 hour.

[0033] After cooling out of the furnace, grind through a 100 mesh (0.15mm) sieve; soak in 1mol / L HCl solution for 1 hour, then rinse and filter with deionized water several times until the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com