Positive photoresist composition and method of forming photoresist pattern

A technology of positive photoresist and photoresist pattern, applied in the field of photolithography, can solve the problems of high production cost, high price of photoacid generator, and high price, and achieve low cost, good film formation and curing effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

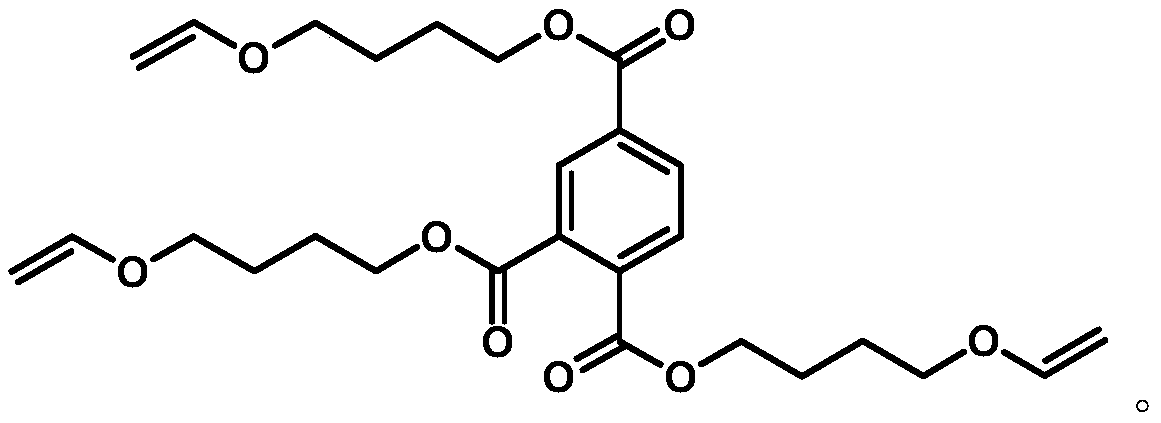

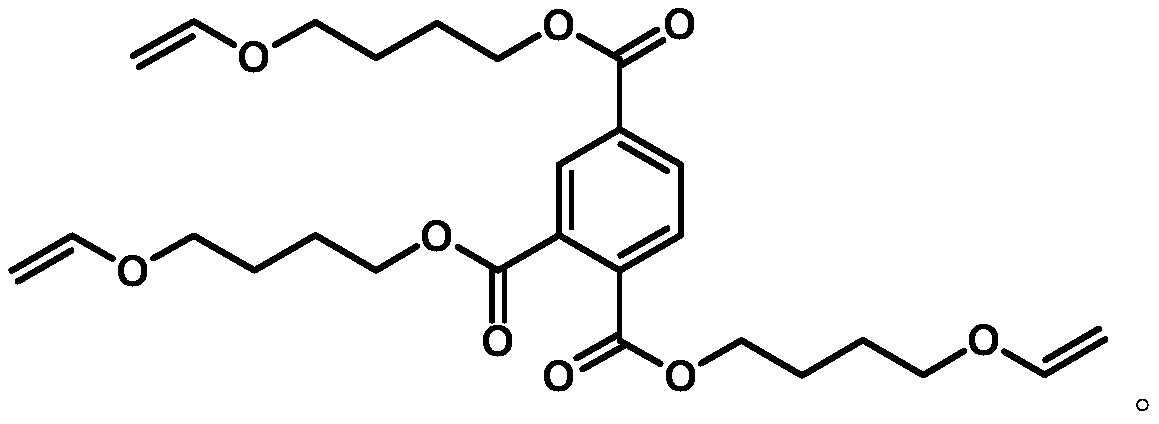

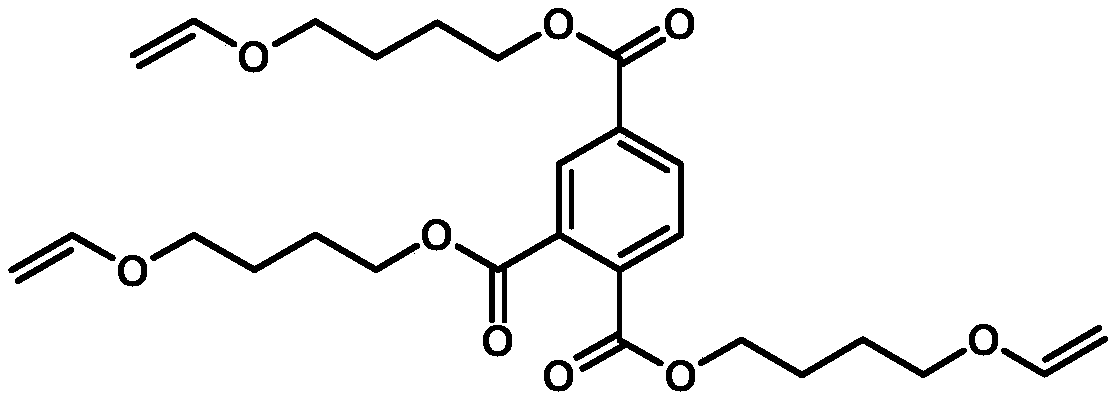

Image

Examples

preparation example Construction

[0073] Preparation of Resin A:

[0074]

[0075] Add 50g of p-cresol, 40g of m-cresol, and 10g of 3,5-dimethylphenol into a 200ml two-necked flask, then add 3.5g of 10wt% succinic acid aqueous solution and heat to 100°C. Afterwards, the 37wt% formaldehyde solution was slowly dripped in for 30 minutes, and after another 30 minutes of reaction, the temperature rose and the moisture slipped out. Then connect the reactor to a vacuum pump to distill out unreacted monomers under a reduced pressure of 10 mmHg. The weight-average molecular weight of the phenolic resin A obtained at last is measured by GPC (gel permeation chromatography), and the average molecular weight is about 3400.

[0076] Preparation of Resin B:

[0077]

[0078] First, the free radical initiator AMBN (azobisisovaleronitrile) was added into 100 g of 2-butanone solvent and stirred until it was completely dissolved, and then used for later use. Add 300g of 2-butanone in a 1000ml three-port reactor, then 31...

Embodiment 1

[0079] Embodiment 1: the preparation of positive photoresist composition

[0080]

[0081] Add 10g of synthetic resin A into 50g of PGMEA (propylene glycol monomethyl ether acetate), stir for 2 hours until completely dissolved, then add 0.2g of photoacid generator iPAG-1 (wherein, R 1 H, purchased from Sigma-Aldrich), 3g cross-linking agent TMTA-BVE (purchased from Kyushu Chemical Co., Ltd.), 0.1g leveling agent MEGAFACE F-563 (purchased from DIC Corporation), and finally add solvent PGME ( Propylene glycol methyl ether) 36.5g, stirred for 2 hours until the solids were all dissolved. Finally, the adjusted sample was filtered with a 0.2 μm filter produced by 3M Company to obtain a positive photoresist composition.

Embodiment 2

[0082] Embodiment 2: the preparation of positive photoresist composition

[0083] The experimental procedure of this embodiment is the same as that of Example 1, the difference is that in this embodiment, the photoacid generator adopts iPAG-2 (wherein, R 1 is H, purchased from Sigma-Aldrich).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com