A method for preparing electrode materials for supercapacitors using current collectors as templates

A technology for preparing electrodes for supercapacitors, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of affecting the electrochemical performance of the battery, reducing the specific capacity of the battery, increasing the quality of the electrode sheet, etc., to reduce the diffusion resistance , Reduce interface resistance, shorten the effect of diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

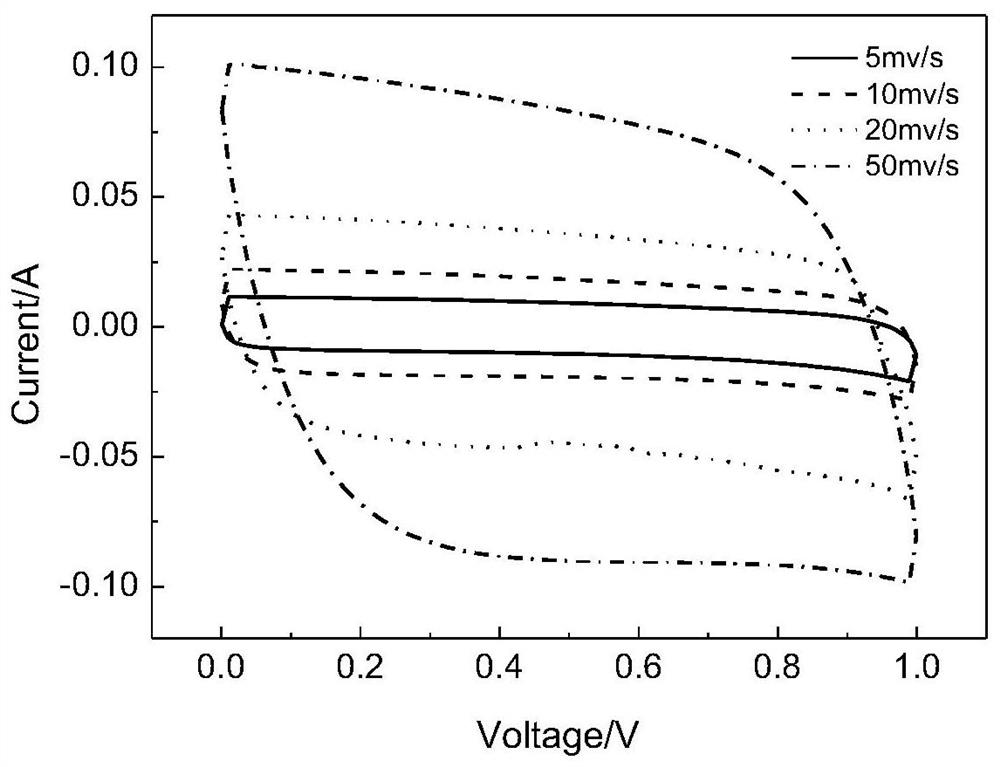

[0028] 4) Preparation of electrode material: After activation, the current collector with electrode material is compacted with a roller press, cut into pieces, and assembled into a battery. 6mol / L KOH solution is used as the electrolyte, and a button-type super is assembled after sealing. Capacitor, the electrochemical performance test was carried out after standing for 12h.

[0029] In the above step 1), the weight ratio of the metal oxide to the current collector is 1-20:100, and the metal oxide includes copper oxide, calcium oxide, zinc oxide, manganese dioxide, aluminum oxide, and iron tetroxide. , one or more of ferric oxide.

[0030] The particle size of the powdery metal oxide in the above step 1) is 10-50 nm.

[0031] The reaction time of the low-temperature pre-deposition in the above step 2) is 2-10 h.

[0032] The flow rate of the gaseous carbon source in the above step 2) is 10 to 100 mL min -1 ;The carrier gas flow is 200~800mL·min -1 , the carrier gas is high...

Embodiment 1

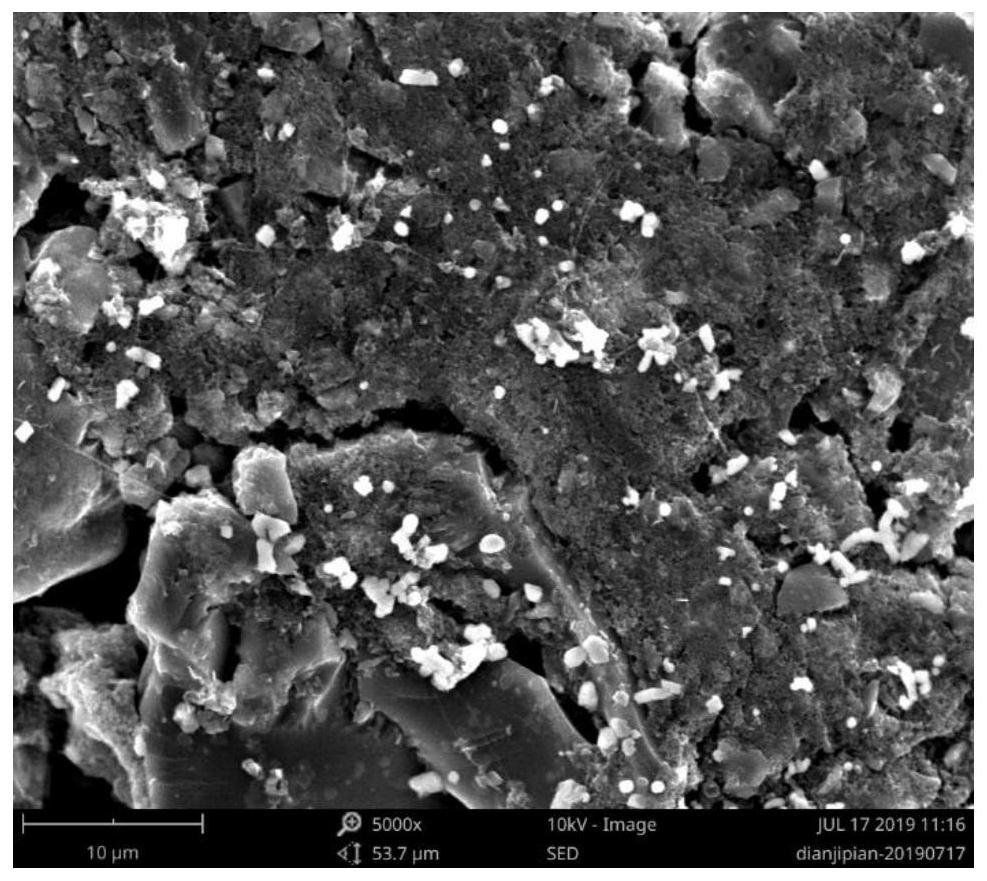

[0038] Using foamed nickel as a template, powdered copper oxide is evenly dispersed on the surface of foamed nickel, and the weight ratio of foamed nickel and powdered copper oxide is 100:10. The carrier gas is high-purity nitrogen, and the carrier gas flow rate is 500mL·min -1, carbon source acetylene gas flow 10mL / min, temperature 400 ℃, low temperature pre-deposition, deposition time 3h. Then carry out chemical vapor deposition, adjust the flow rate of the carrier gas to 800mL / min, adjust the flow rate of the acetylene carbon source to 50mL / min, adjust the chemical vapor deposition furnace, with a heating rate of 5°C / min to a reaction temperature of 800°C, a deposition time of 60min, and the reaction After the end, the current collector on which the carbon material is deposited is taken out. The current collector containing the in-situ deposited carbon material was placed on a white steel mesh, moved into an activation furnace, and heated to 600 °C at a heating rate of 5 °...

Embodiment 2

[0040] Using foamed nickel as a template, powdered ferric ferric oxide is evenly dispersed on the surface of foamed nickel, and the weight ratio of foamed nickel to powdered ferric ferric oxide is 100:5, and is placed at the end of the quartz tube of the chemical vapor deposition furnace. The quartz boat containing 50g of coal tar samples was put into the front end of the quartz tube, and the carrier gas high-purity argon was first introduced for pre-deposition, and the carrier gas flow was 600mL·min -1 , the temperature is 300 ℃, the sample is placed in the heating zone, and the low temperature pre-deposition is carried out, and the deposition time is 4h. Then carry out chemical vapor deposition, adjust the carrier gas flow rate to 600mL / min, adjust the chemical vapor deposition furnace, with a heating rate of 5°C / min to a reaction temperature of 700°C, deposition time of 30min, and after the reaction is completed, a current collector of carbon material is deposited take out....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com