Method for preparing lithium-sulfur battery positive electrode material from three-dimensional mesoporous biochar

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, active material electrodes, etc., can solve the problems of storing sulfur substances, unable to provide large pore volume, etc., to improve electrical conductivity, good electrochemical advantages, The effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A method for preparing a three-dimensional mesoporous biocarbon-made lithium-sulfur battery positive electrode material, the specific steps are as follows:

[0022] Step 1: Add 25 grams of glucose, 7.5 grams of yeast powder, 10 grams of peptone, and 10 grams of disodium hydrogen phosphate into a large beaker filled with ultrapure water in sequence, stir the solution until it is clear, then add glacial acetic acid dropwise until pH = 4- 5. Obtain the bacterial growth solution;

[0023] Step 2: Pour the bacterial growth liquid into the Erlenmeyer flask, put it into a high-temperature sterilization box at 155°C for 30 minutes, and air-cool the sterilized growth liquid to room temperature, then transfer the strain of Acetobacter xylinum into the Cultivate in an incubator at 30°C for 7 days to form a pale yellow BC liquid gel;

[0024] Step 3: Soak the pale yellow BC liquid gel in deionized water at 80° C. for 5 hours, and then purify it in 0.5 mol / L NaOH solu...

Embodiment 2

[0032] Example 2: Preparation of three-dimensional mesoporous biochar S@CoS 2 / N-CNFs (40%) the method of lithium-sulfur battery cathode material, in embodiment 2, except that step 4 is different from the step in embodiment 1, other steps are all the same. In step four, 0.2 g of CoCl 2 ·6H 2 O, 0.4 g Na 2 S 2 o 3 ·5H 2 O and 0.067 g of melamine were dissolved in 30 mL of deionized water containing 0.1 g of bacterial cellulose airgel and subjected to hydrothermal synthesis at 130 °C for 12 h to obtain 50% CoS 2 The nitrogen doping amount under 40% hydrothermal product, denoted as CoS 2 / 40%N-BC, thus preparing the cathode material S@CoS for lithium-sulfur batteries 2 / N-CNFs (40%), and a button battery corresponding to the cathode material was prepared.

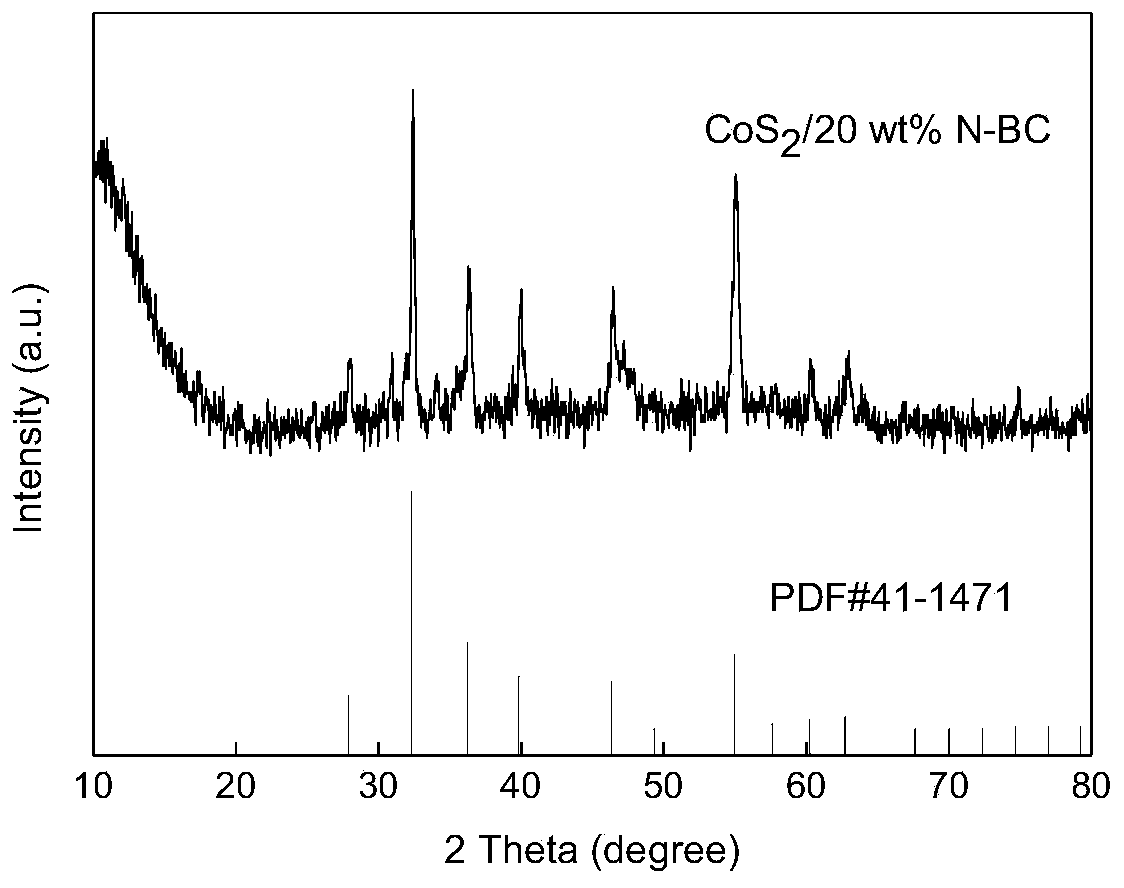

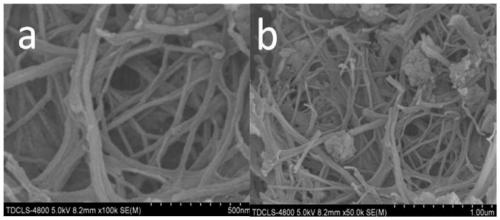

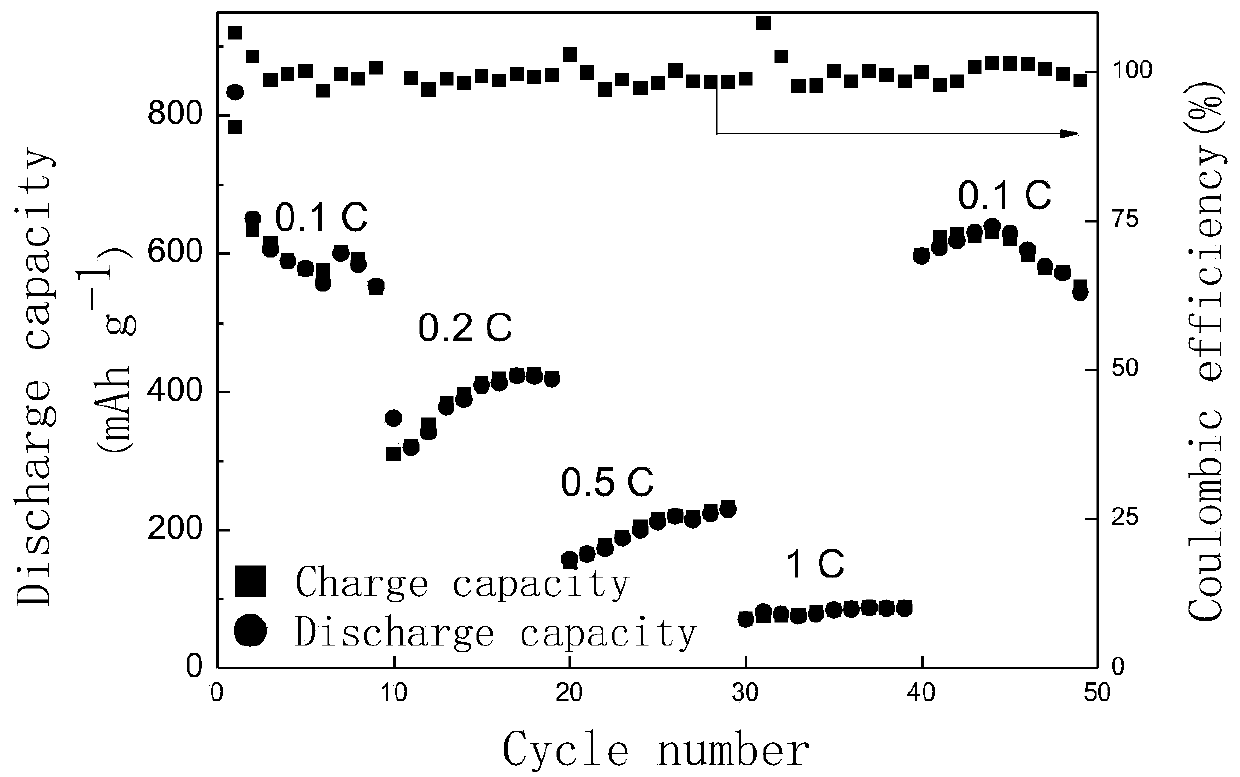

[0033] Figure 4 and Figure 5 Respectively the CoS that embodiment 2 makes 2 / N-CNFs (40%) X-ray diffraction patterns and scanning electron microscope topography, Figure 4 shows that the 40% N doping in Example 2...

Embodiment 3

[0034] Example 3: Preparation of three-dimensional mesoporous biochar S@CoS 2 / N-CNFs (60%) lithium-sulfur battery cathode material method, in embodiment 3, except that step 4 is different from the step in embodiment 1, other steps are the same. In step four, 0.2 g of CoCl 2 ·6H 2 O, 0.4 g Na 2 S 2 o 3 ·5H 2 O and 0.15 g of melamine were dissolved in 30 mL of deionized water containing 0.1 g of bacterial cellulose airgel and subjected to hydrothermal synthesis at 130 °C for 12 h to obtain 50% CoS 2 The nitrogen doping amount under 60% hydrothermal product, denoted as CoS 2 / 60%N-BC, thus preparing the cathode material S@CoS for lithium-sulfur batteries 2 / N-CNFs (60%), and a button battery corresponding to the cathode material was prepared.

[0035] Figure 7 and Figure 8 Respectively the CoS that embodiment 3 makes 2 / N-CNFs (60%) X-ray diffraction patterns and scanning electron microscope topography, Figure 7 showed that the 60% N doping in Example 3 did not af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com