Method for preparing functional yoghourt through ultrahigh-pressure sterilization

An ultra-high pressure sterilization, functional technology, applied in the preservation of milk, dairy products, milk preparations, etc., can solve the problems of viscosity loss, whey precipitation, protein denaturation, etc., to achieve a stable product system, no viscosity loss, Avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] 1) Mix the raw materials for the preparation of functional yogurt to obtain a mixture, inoculate the mixture with fermentation bacteria, and ferment at 40-43°C until the acidity is 70-80°T to obtain a yogurt base; Raw materials include phytosterol esters;

[0021] 2) Ultra-high pressure sterilization is performed on the yogurt base; the pressure of the ultra-high pressure sterilization is 400-800 MPa, the holding time is 5-20 minutes, and the temperature is 15-30°C.

[0022] In the present invention, the raw materials for the preparation of functional yogurt are firstly mixed to obtain a mixture, the mixture is inoculated with fermentation bacteria, and fermented at 40-43°C until the acidity is 70-80°T, preferably 75°T, to obtain yogurt Base material; the raw materials for preparation include phytosterol esters, which can reduce the content of low-density cholesterol in the blood after being ingested by the human body, and play a role in cardiovascular health care; the ...

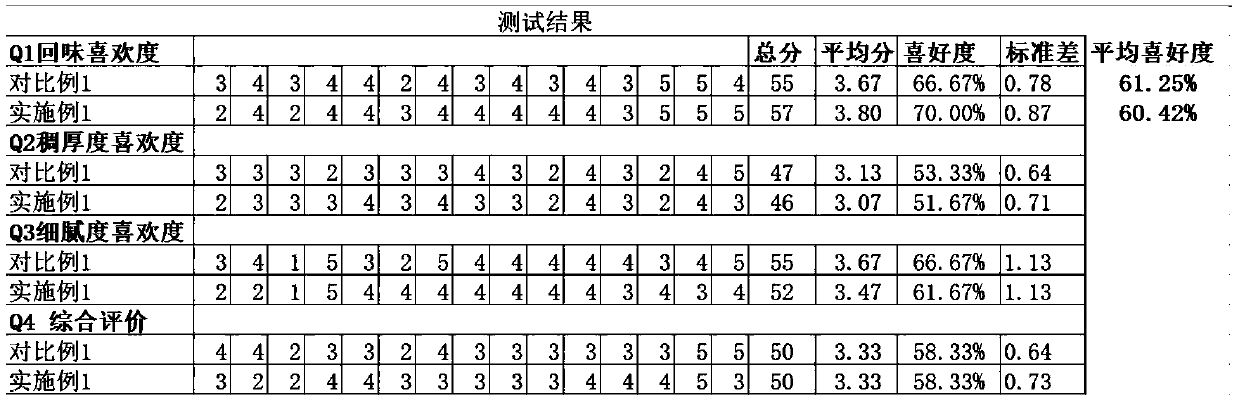

Embodiment 1

[0033] Example 1 A method for preparing functional yoghurt by ultrahigh pressure sterilization

[0034] 1. The autoclaving method used is static ultra-high pressure sterilization, the sterilization pressure is 600Mpa, the time is 10min, and the temperature is 20°C.

[0035] 2. The raw materials for preparing the yogurt base include 86% of raw milk, 6% of sucrose, 2.0% of stabilizer, 0.3% of whey protein powder, 0.15% of phytosterol ester, 0.006% of bacterial strain, and the balance is water .

[0036] Wherein the stabilizer is hydroxypropyl distarch phosphate, a mixture of acetylated distarch phosphate, agar, and pectin, the mass ratio of the four materials is 4.5:4:1:0.5, that is, hydroxypropyl The addition of distarch phosphate is 0.9%, the addition of acetylated distarch phosphate is 0.8%, the addition of agar is 0.2%, and the addition of pectin is 0.1%.

[0037] The whey protein powder is whey protein powder derived from cheese by-products.

[0038] The bacterial species ...

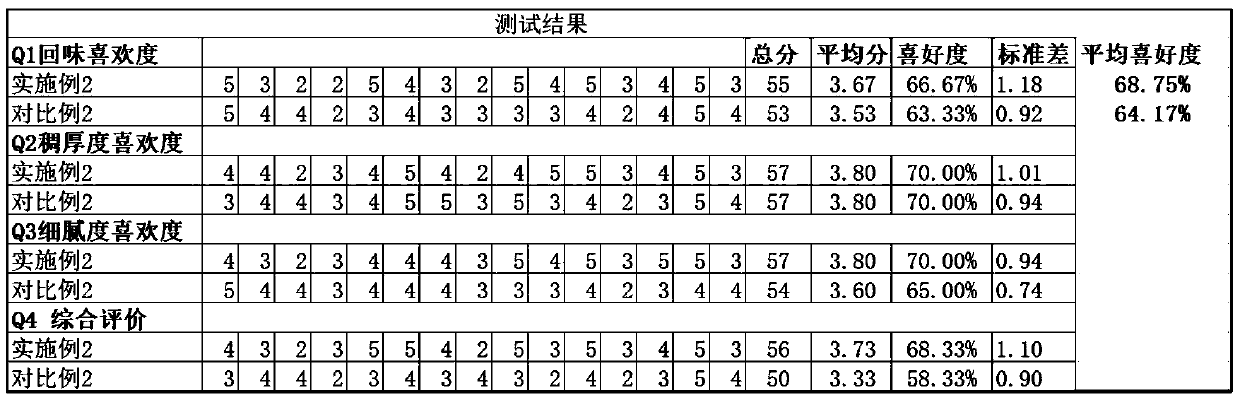

Embodiment 2

[0046] Example 2 A method for preparing functional yoghurt by ultrahigh pressure sterilization

[0047] 1. The autoclaving method used is static ultra-high pressure sterilization, the sterilization pressure is 400Mpa, the temperature is 20°C, and the time is 15min.

[0048] 2. The raw materials for preparing the yogurt base material include 88% of raw milk, 7% of sucrose, 1.6% of stabilizer, 0.4% of whey protein powder, 0.2% of phytosterol ester, 0.005% of bacterial strain, and the balance is water .

[0049] The stabilizer is a mixture of hydroxypropyl distarch phosphate and agar, and the mass ratio of the two is 8:2, that is, the added amount of hydroxypropyl distarch phosphate is 1.28%, and the added amount of agar is 0.32%.

[0050] The whey protein powder is whey protein powder derived from acid precipitation.

[0051] The bacterial species is a mixture of Streptococcus thermophilus and Bifidobacterium, and the ratio of the effective number of viable bacteria added by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com