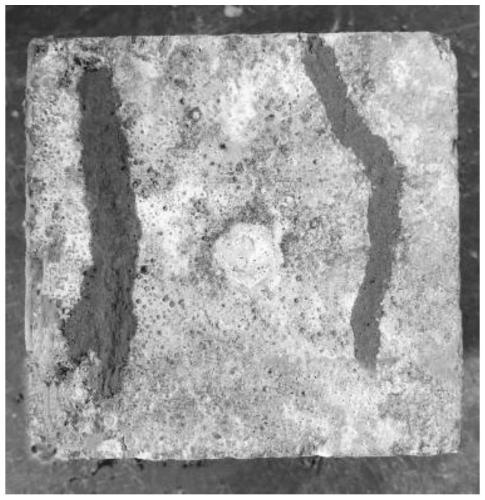

Concrete crack repairing additive, and preparation and use methods thereof

A technology of concrete and additives, applied in building maintenance, construction, building construction, etc., can solve problems such as poor strength and poor durability, and achieve the effects of improving compactness and strength, improving viscosity performance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

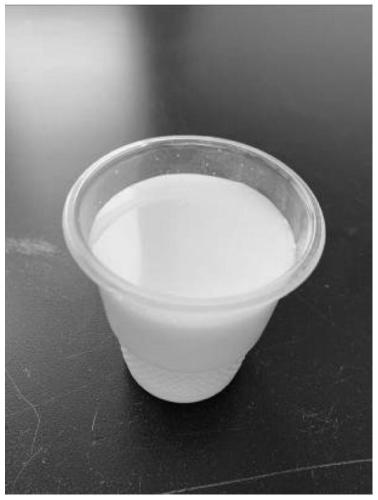

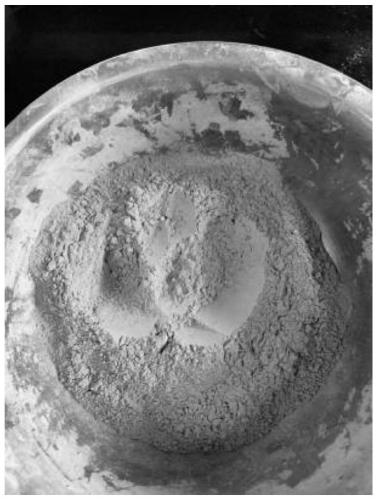

[0064] According to the weight ratio of each component in Table 1, each raw material was weighed. Put each raw material into the mixer, stir at a low speed first, and preliminarily mix each component, the stirring speed is 500 rpm, and the stirring time is 3 minutes; let it stand for 40 seconds, and then stir at a high speed, the stirring speed is 2500 rpm, and the stirring time is 5 minutes. Get repair mortar material. The test results are shown in Table 1.

[0065] Among them, the silicone resin emulsion is Dow Corning 6683 silicone resin emulsion (the main components are organosilane and silicate); the water reducer is polyhydroxy acid water reducer; the defoamer is polyether defoamer; The agent is propylene glycol butyl ether. The cement adopts 42.5 type ordinary Portland cement; the admixture is fly ash; the sand is medium sand with a fineness modulus of 2.2.

Embodiment 2

[0067] According to the weight ratio of each component in Table 1, each raw material was weighed. The preparation method is the same as in Example 1. Put each raw material into the mixer, stir at a low speed first, and preliminarily mix each component, the stirring speed is 400 rpm, and the stirring time is 3 minutes; let it stand for 30 seconds, and then stir at a high speed, the stirring speed is 2000 rpm, and the stirring time is 4 minutes. Get repair mortar material. The test results are shown in Table 1.

[0068] Among them, the silicone resin emulsion is SH9608 silicone resin emulsion (the main component is organosiloxane) of New Sihai Company; the water reducer is polyhydroxyacid water reducer; the defoamer is polyether defoamer; For ethylene glycol monopropyl ether. The cement is Portland cement of type 42.5; the admixture is granulated blast furnace slag powder; the sand is medium sand with a fineness modulus of 2.2.

Embodiment 3

[0070] According to the weight ratio of each component in Table 1, each raw material was weighed. The preparation method is the same as in Example 1. Put each raw material into the mixer, stir at a low speed first, and preliminarily mix each component, the stirring speed is 600 rpm, and the stirring time is 2 minutes; let it stand for 20 seconds, and then stir at a high speed, the stirring speed is 1500 rpm, and the stirring time is 5 minutes. Get repair mortar material. The test results are shown in Table 1.

[0071] The silicone resin emulsion is Dow Corning 6683 silicone resin emulsion; the water reducer is a naphthalene water reducer; the defoamer is a polyether defoamer; and the film forming agent is propylene glycol methyl ether acetate. Ordinary Portland cement is used for cement; silica fume is used as admixture; medium sand with fineness modulus 2.1 is used for sand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com