Anti-bacterial and anti-tearing textile fabric and production process thereof

A technology for textile fabrics and tear resistance, applied in the field of textile fabrics, can solve the problem of no filtering and other problems, and achieve the effects of reducing thermal degradation, improving breaking strength, and improving antistatic ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

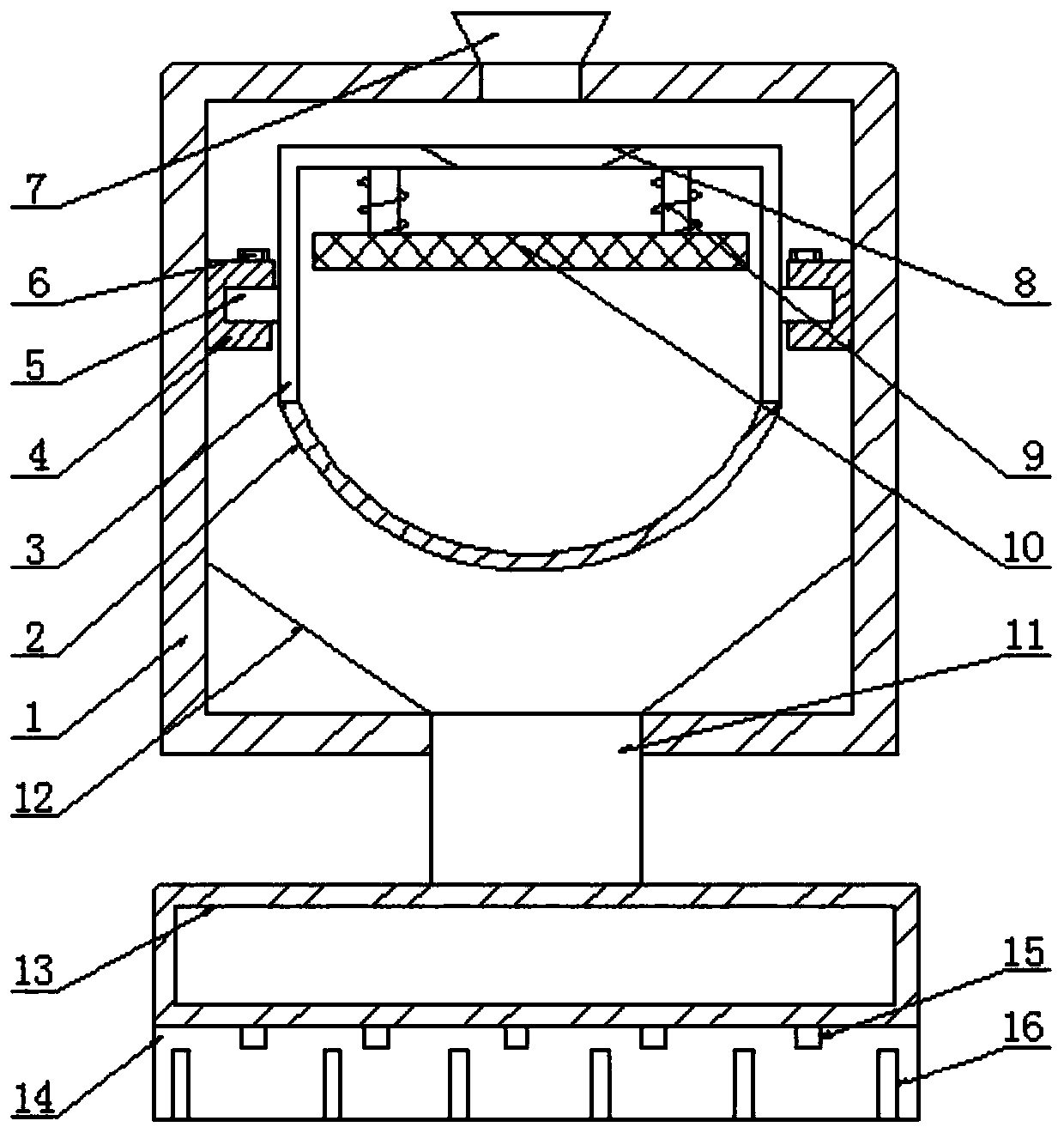

Image

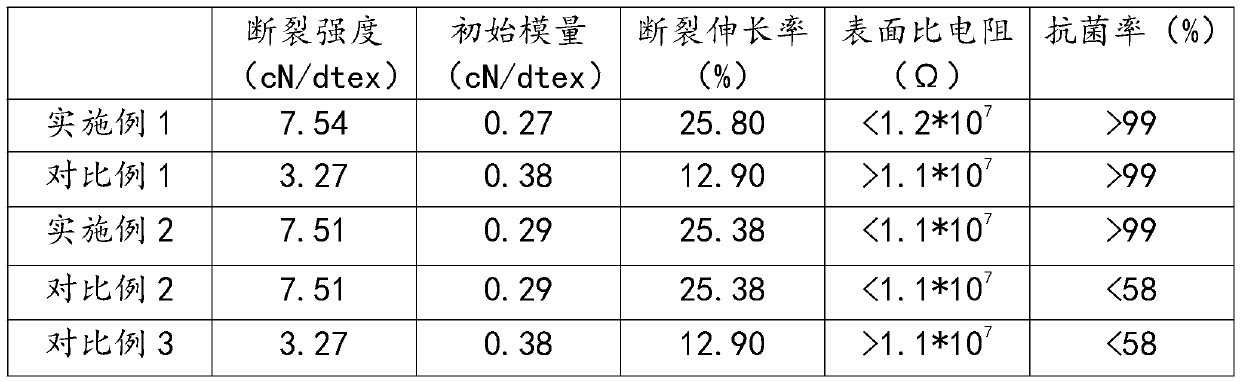

Examples

Embodiment 1

[0033] An antibacterial, tear-resistant textile fabric, the fabric is woven from warp threads, weft threads and polyester high-strength yarns, and the warp threads include 60 parts of cotton fiber, 5 parts of shell fiber, 1 part of bamboo fiber, and 1 part of Antibacterial agent and 3 parts of spandex fibers; said weft comprises 30 parts of acrylonitrile, 18 parts of vinyl chloride, 5 parts of carbon black, 2 parts of metal oxide, 0.5 part of pore-forming agent and 0.5 part of screen agent by weight;

[0034] The preparation of the polyester high-strength yarn comprises the following steps:

[0035] 1) 35 parts of purified terephthalic acid, 15 parts of ethylene glycol, 11 parts of ethylene glycol antimony and 1 part of ethylene oxide organic compound are polymerized into a low-viscosity polyester melt through a five-pot polymerization device, and then transported to the liquid Polycondensation in a viscosifying reactor to obtain a high-viscosity melt;

[0036] 2) After the h...

Embodiment 2

[0045] An antibacterial, tear-resistant textile fabric, the fabric is woven from warp threads, weft threads and polyester high-strength silk, and the warp threads include 80 parts of cotton fiber, 10 parts of shell fiber, 6 parts of bamboo fiber, and 3 parts by weight. Antibacterial agent and 8 parts of spandex fibers; the weft includes 55 parts of acrylonitrile, 35 parts of vinyl chloride, 8 parts of carbon black, 5 parts of metal oxides, 1 part of pore-forming agent and 1 part of screen agent by weight;

[0046] The preparation of the polyester high-strength yarn comprises the following steps:

[0047] 1) 45 parts of purified terephthalic acid, 20 parts of ethylene glycol, 20 parts of ethylene glycol antimony and 2 parts of ethylene oxide organic compound are polymerized into a low-viscosity polyester melt through a five-pot polymerization device, and then transported to the liquid Polycondensation in a viscosifying reactor to obtain a high-viscosity melt;

[0048] 2) After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com