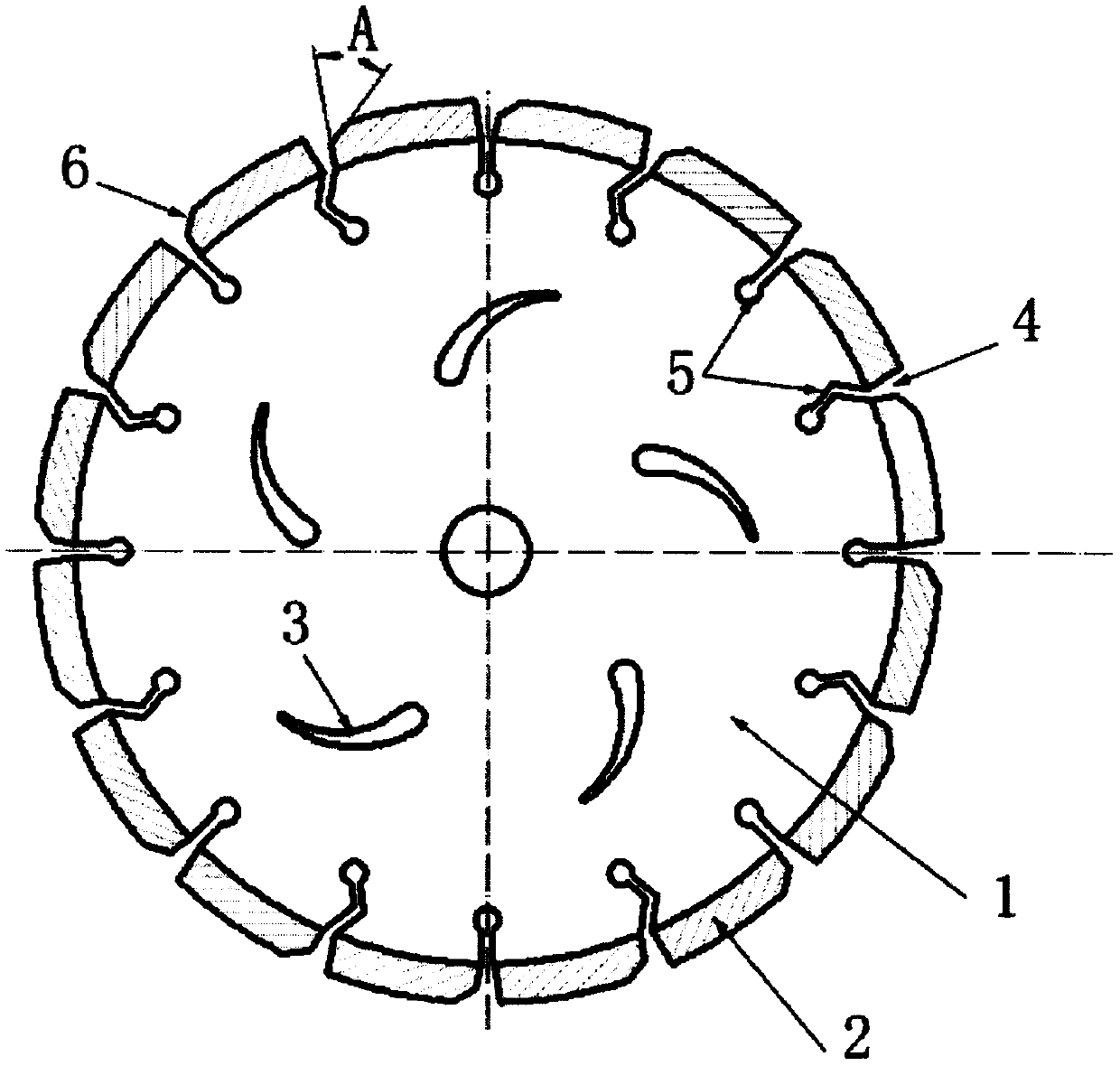

Diamond saw blade and preparation process thereof

A diamond saw blade and preparation technology, which is applied in the direction of manufacturing tools, stone processing equipment, stone processing tools, etc., can solve the problems of increased thermal stress between diamond and carcass, and diamond particle shedding, so as to reduce cutting resistance and thermal expansion Good coefficient and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation process of the present embodiment diamond saw blade is as follows:

[0048] 1. Substrate processing: The substrate is 30CrMo steel with a hardness of 34-38HRC.

[0049] According to the requirements of the drawings, the saw blade base of the required structure is prepared by machining;

[0050] 2. Preparation of diamond cutter head:

[0051] The composition of the raw materials used for the diamond cutter head is (parts by weight):

[0052] 38 parts of iron, 21 parts of nickel, 15 parts of cobalt, 12.5 parts of tungsten, 6.5 parts of chromium, 16.5 parts of molybdenum, 15 parts of tin, 2 parts of phosphorus alloy, 2 parts of liquid paraffin, 1.8 parts of diamond;

[0053] In the phosphorus alloy, the phosphorus content is 8wt.%, and the rest is iron; the particle size of the diamond is 50 / 60 mesh, and the compressive strength of the diamond is 25-40kg.

[0054] The diamond cutter head is prepared by hot pressing sintering technology: the raw materials...

Embodiment 2

[0074] The difference from Example 1 is:

[0075] The composition of the raw materials used for the diamond cutter head is (parts by weight):

[0076] 35.5 parts of iron, 20.5 parts of nickel, 15.8 parts of cobalt, 13.25 parts of tungsten, 8 parts of chromium, 17.2 parts of molybdenum, 14.4 parts of tin, 2.05 parts of phosphorus alloy, 2 parts of liquid paraffin, and 1.8 parts of diamond;

[0077] The hardness (HRB) of the prepared diamond tip is about 108.

[0078] The diamond saw blade weld seam prepared in this example has no macroscopic defects such as holes, cracks, and incomplete penetration. The bending strength is 605MPa, the hardness is 98HRB, and the impact toughness is 5.02J / cm2.

[0079] The maximum deformation of the substrate of the diamond saw blade after welding is 0.06mm, and the minimum stress deformation is 0mm. It shows that the residual stress between the welding sheet cutter head and the matrix prepared in this example is small, and the matrix has high...

Embodiment 3

[0081] The difference from Example 1 is:

[0082] The composition of the raw materials used for the diamond cutter head is (parts by weight):

[0083] 40 parts of iron, 22 parts of nickel, 18 parts of cobalt, 12 parts of tungsten, 6.8 parts of chromium, 16.4 parts of molybdenum, 14.5 parts of tin, 2 parts of phosphorus alloy, 2 parts of liquid paraffin, 22.0 parts of diamond;

[0084] The hardness (HRB) of the prepared diamond tip is about 108.

[0085] The diamond saw blade weld seam prepared in this example has no macroscopic defects such as holes, cracks, and incomplete penetration. The bending strength is 609MPa, the hardness is 100.2HRB, and the impact toughness is 5.15J / cm2.

[0086] The maximum deformation of the substrate of the diamond saw blade after welding is 0.05mm, and the minimum stress deformation is 0mm. It shows that the residual stress between the welding sheet cutter head and the matrix prepared in this example is small, and the matrix has high strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com