Preparation method and application of carbon-coated tin selenide negative electrode material

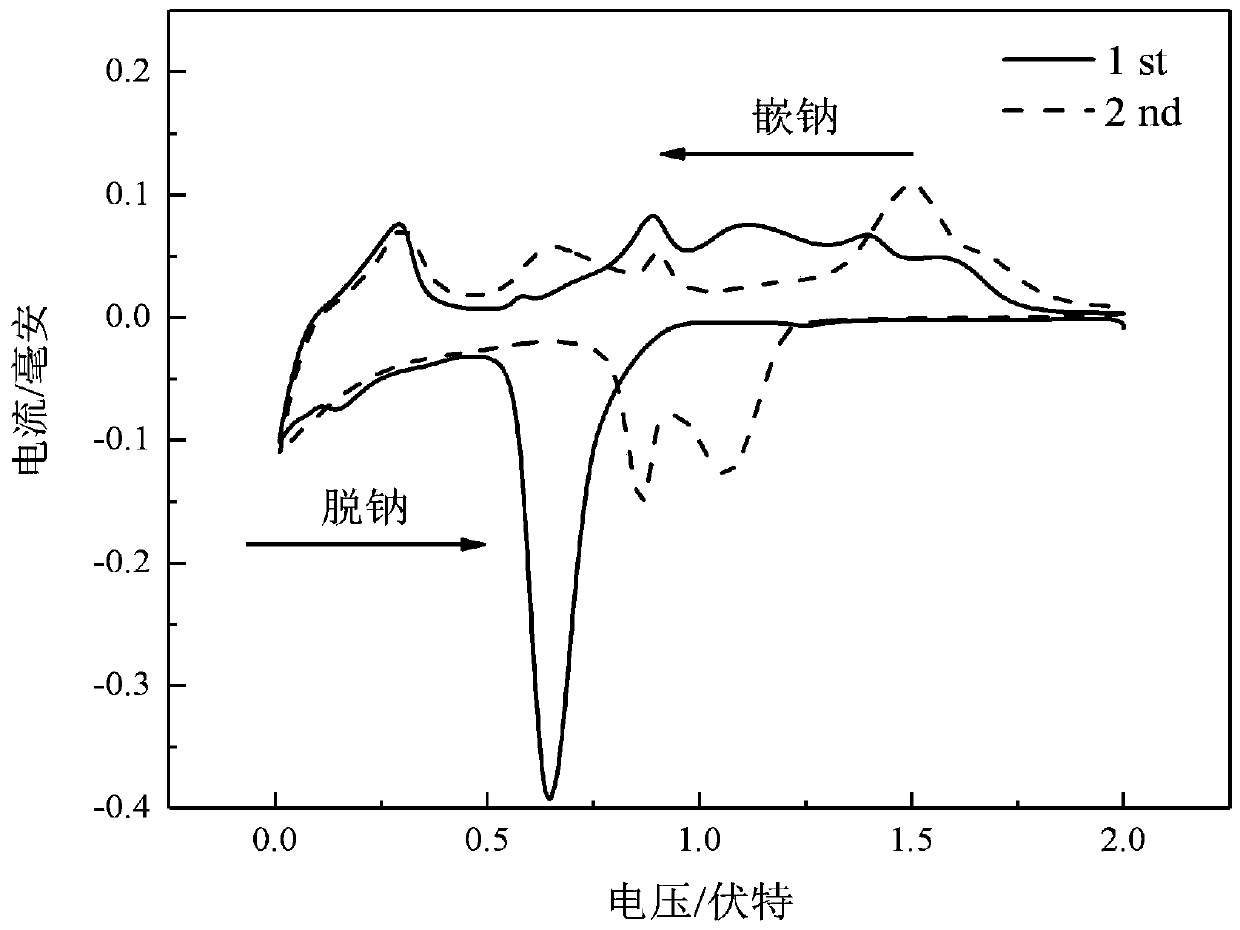

A technology of negative electrode material and carbon package, which is applied in the field of preparation of carbon-coated tin selenide negative electrode material, can solve the problems of SnSe negative electrode material such as poor conductivity, poor cycle stability, and poor rate performance, and achieve good electrochemical performance and easy operation , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

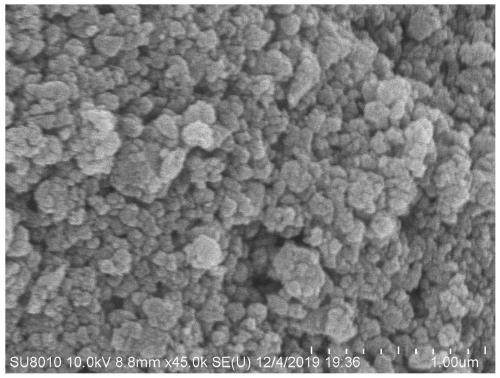

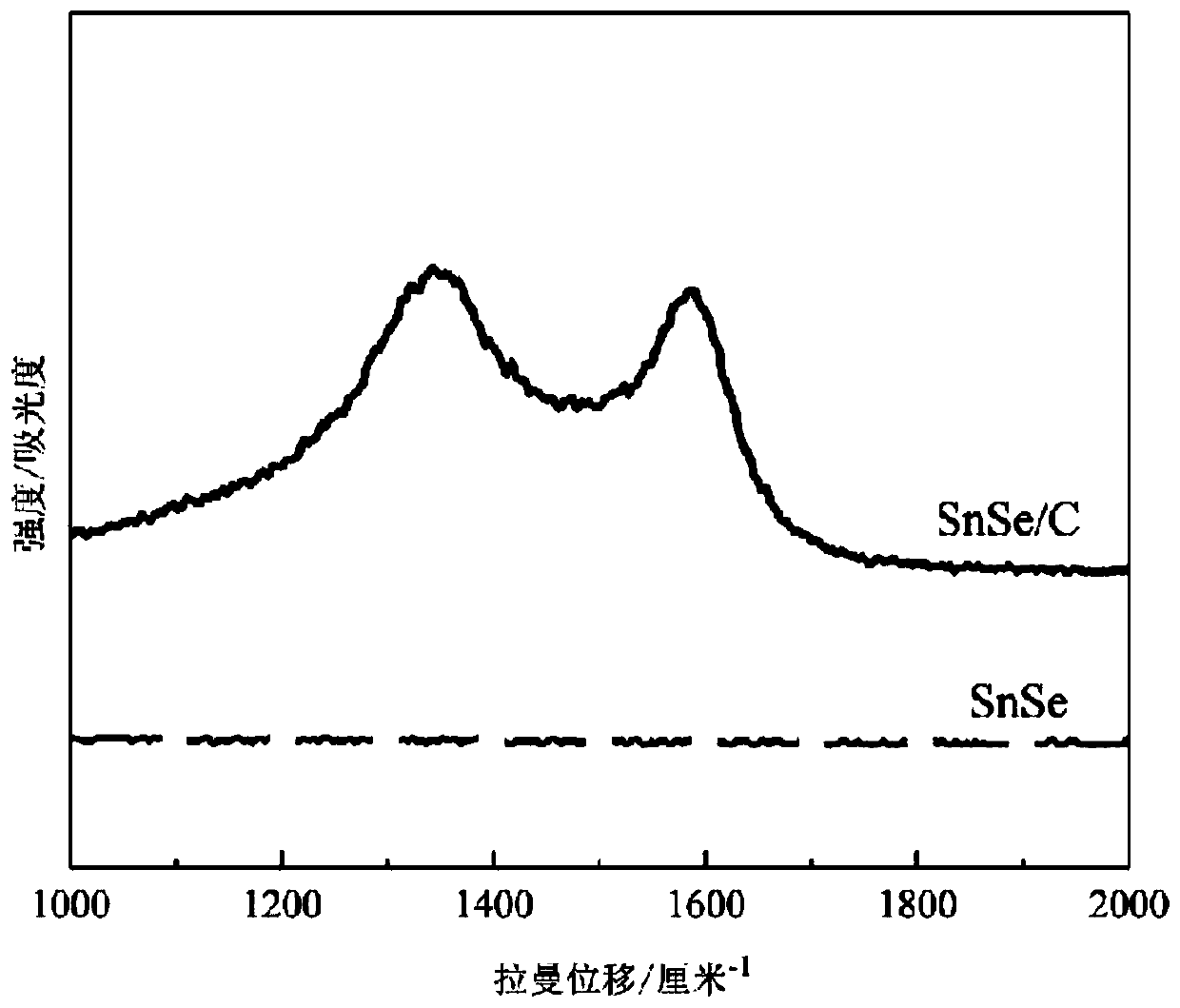

[0027] Specific embodiment one: what this embodiment records is a kind of preparation method of carbon-coated tin selenide negative electrode material, and the specific steps of described method are as follows:

[0028] Step 1: Mix Sn powder and Se powder in a molar ratio of 1:1, transfer them into a vacuum quartz tube, and use a tube furnace for high-temperature calcination;

[0029] Step 2: Grinding and sieving the SnSe powder obtained by calcining, and mixing the sieved product with a carbon source;

[0030] Step 3: Perform high-energy ball milling treatment under an inert atmosphere, and sieve to obtain the product;

[0031] Step 4: annealing to form a SnSe powder whose surface is covered with a compact and uniform carbon layer.

specific Embodiment approach 2

[0032] Embodiment 2: In the method for preparing a carbon-coated tin selenide negative electrode material described in Embodiment 1, in step 1, the temperature of the high-temperature calcination is 590° C., the time is 72 hours, and the degree of vacuum is ≤200 Pa.

specific Embodiment approach 3

[0033] Embodiment 3: In the method for preparing a carbon-coated tin selenide negative electrode material described in Embodiment 1, in step 2, the mass ratio of the carbon source to the total mixture is 10wt.%-40wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com