Method for preparing monocrystalline silicon film and silicon P-N junction through high-temperature fused salt electro-deposition

A technology of high-temperature molten salt and electrodeposition, applied in the field of semiconductors, to achieve the effects of improving production efficiency, reducing production energy consumption, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

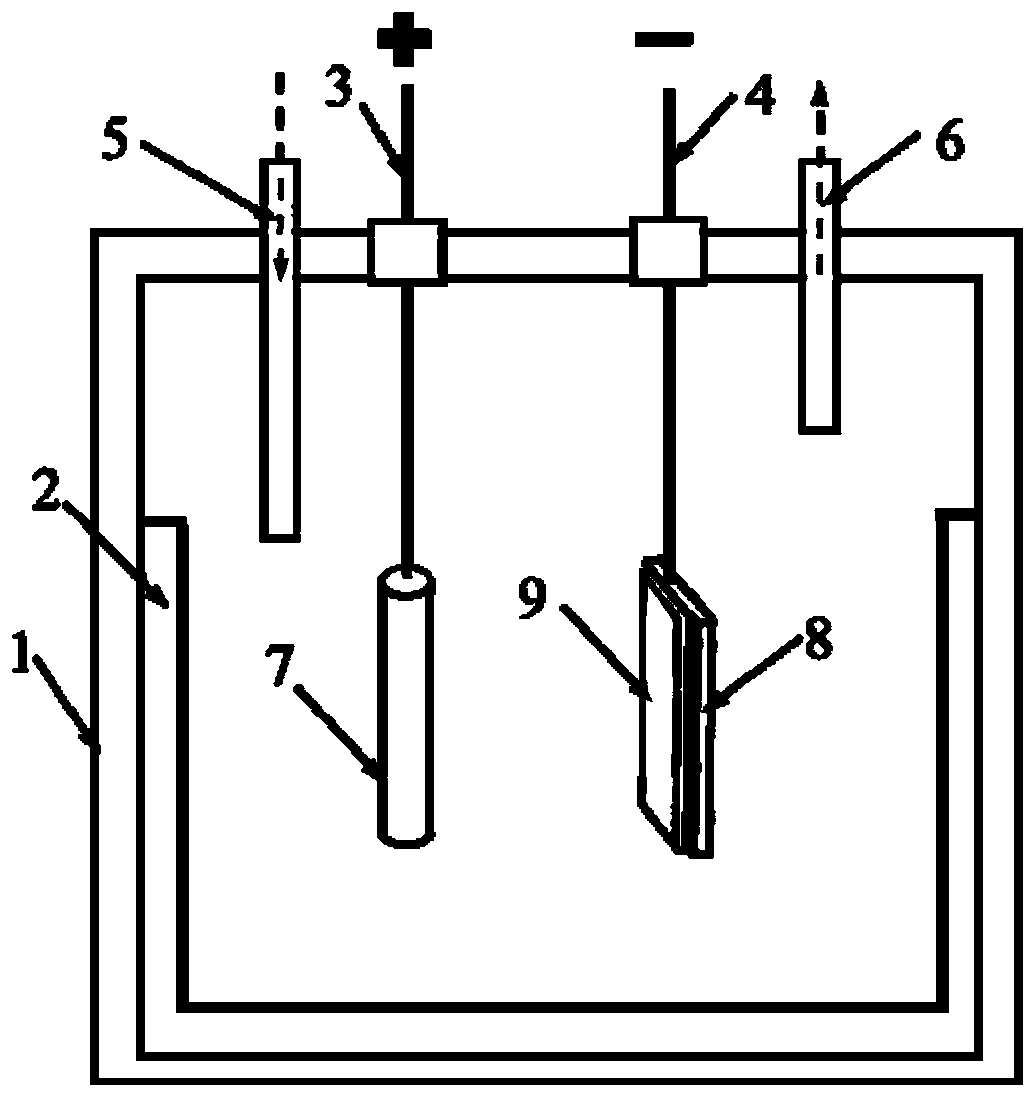

[0042] In this embodiment, the specific operation steps are as follows:

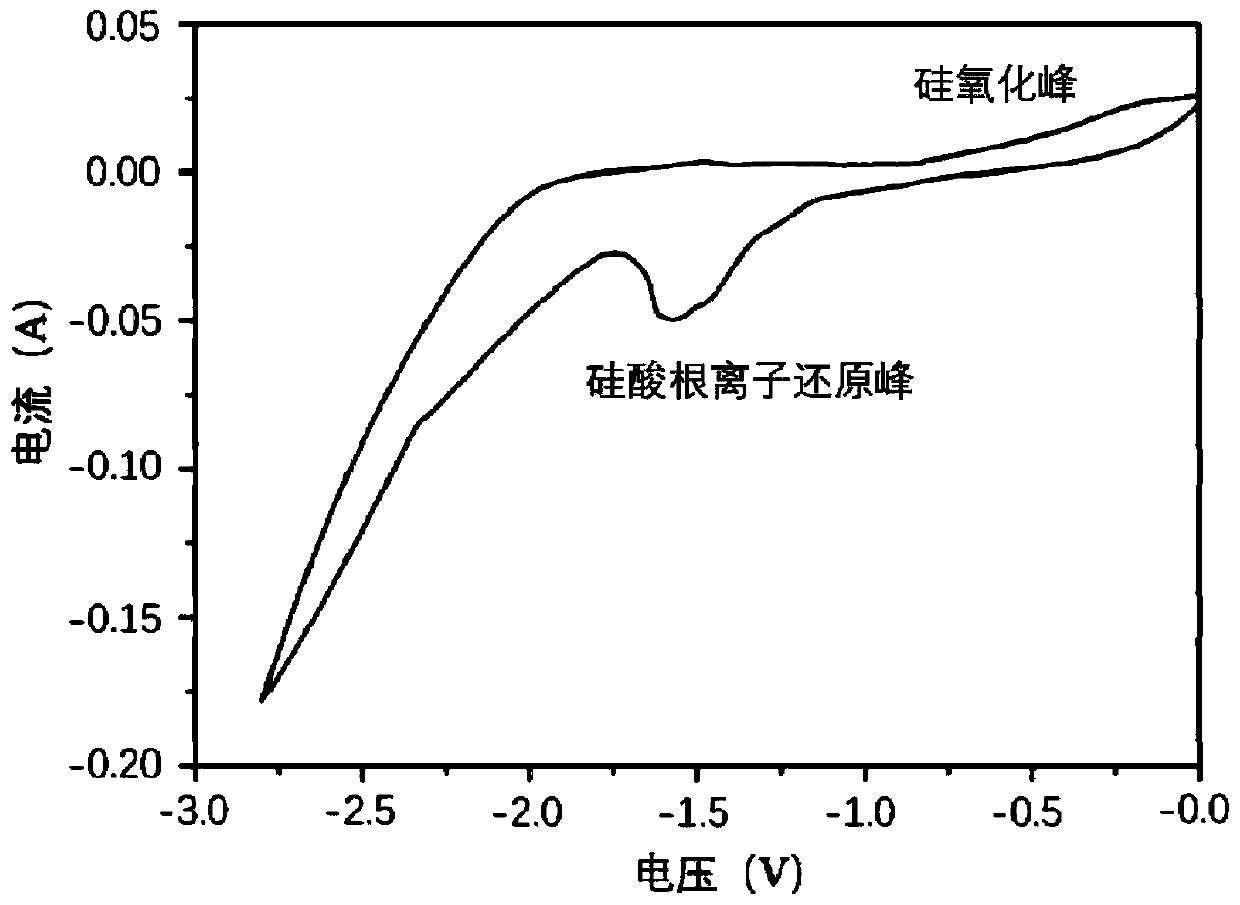

[0043] (75g) CaCl 2 -(2.0g)SiO2 2 - (2.0 g) CaO raw material was added into a high-purity quartz crucible, and the temperature was raised to 500° C. under a high-purity argon atmosphere, and kept for 24 hours. Then it was heated to 850°C under high-purity argon atmosphere and kept for 48h. Two high-purity graphite rods were used as anode and cathode, and put into a crucible for pre-electrolysis. The pre-electrolysis voltage was 2.5V and the time was 12h. After the pre-electrolysis, a high-purity graphite rod was put in again as the anode of the electrolytic cell, and the P-type monocrystalline silicon wafer [100] was used as the cathode of the electrolytic cell, that is, the substrate of the product, for electrodeposition, and the obtained cyclic voltammetry curve was as follows figure 2 shown. This example uses Ca 3 (PO 4 ) 2 as a source of doping elements. This time the current density was 15m...

Embodiment 2

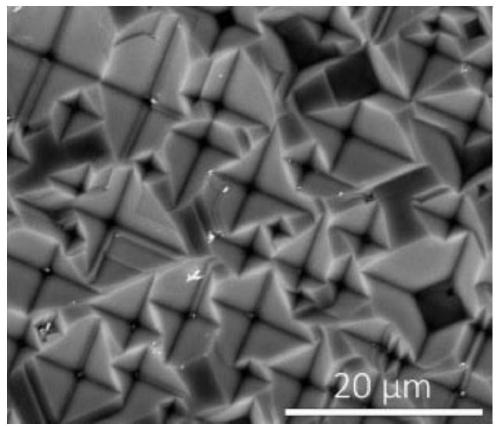

[0045] The implementation of this case is roughly the same as Example 1, but the electrodeposition time is 1h, and the surface morphology of the obtained product is as follows Figure 5 As shown, the cross-section Figure 6 shown. It can be seen that the surface of the epitaxially grown silicon film is still composed of inverted pyramids, and the thickness of the deposited single crystal silicon film is about 3 μm.

Embodiment 3

[0047] (75g) CaCl 2 -(1.8g) SiO2 2 - (1.6g) CaO raw material was added into a high-purity quartz crucible, and the temperature was raised to 500° C. under a high-purity argon atmosphere, and kept for 24 hours. Then it was heated to 850°C under high-purity argon atmosphere and kept for 48h. Two high-purity graphite rods were used as anode and cathode, and put into a crucible for pre-electrolysis. The pre-electrolysis voltage was 2.5V and the time was 12h. Then perform intermittent pre-electrolysis three times. During electrodeposition, a high-purity graphite rod was placed again as the anode of the electrolytic cell, and the P-type monocrystalline silicon wafer in the [100] direction was used as the cathode of the electrolytic cell, that is, the substrate of the product. This time, Ca was used for doping. 3 (PO 4 ) 2 As a source of doping elements, a small amount of Ca is added to the electrolytic cell 3 (PO 4 ) 2 , and applied a constant voltage of 2.4V for continuous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com