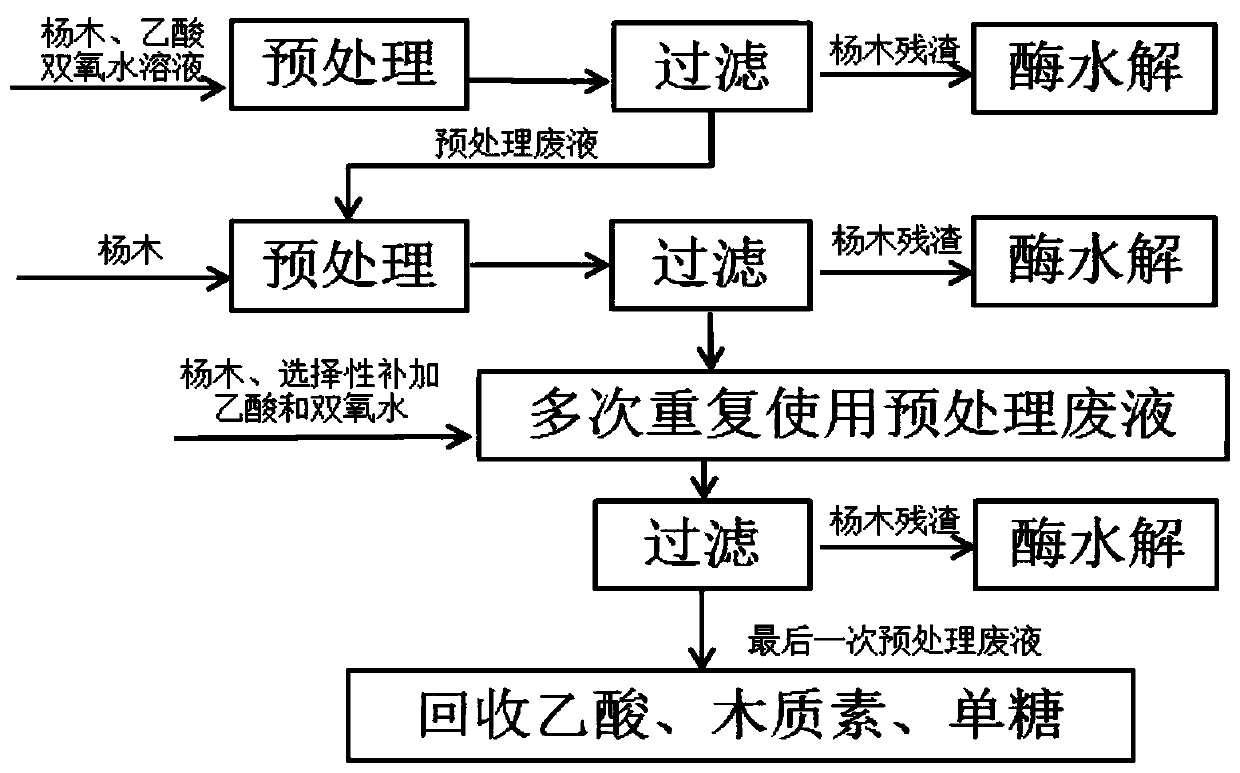

Method for removing poplar lignin by cyclic utilization of acetic acid-hydrogen peroxide pretreatment liquid

A technology of pretreatment liquid and hydrogen peroxide, which is applied in the field of forestry biomass degradation and conversion, can solve the problems of difficult recycling, high consumption, and high concentration of pretreatment liquid, and achieve the effect of reducing costs and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh poplar wood with a dry weight of 10g (with a lignin content of 27.9%), add 100% volume concentration of acetic acid-hydrogen peroxide solution and 100mM sulfuric acid at a solid-to-liquid ratio of 1:10, and pretreat at 80°C for 2h. Cooling after pretreatment, discharge, use vacuum pump to filter, separate solid and liquid, and the solid residue can be used to prepare monosaccharide or as biomass material. The pretreated waste liquid is mixed with the new poplar raw material according to the material-to-liquid ratio of 1:10, pretreated at 80°C for 2 hours, cooled, unloaded, filtered by a vacuum pump, separated from solid and liquid, and the solid residue is washed with water until neutral for enzymatic hydrolysis . The pretreatment waste liquid is used for the poplar pretreatment next time again, and the pretreatment liquid is repeatedly used 4 times according to the aforementioned steps.

[0046] Weigh 1g of pretreated poplar in a Erlenmeyer flask, add 20FPU cell...

Embodiment 2

[0053] The pretreatment method and reaction conditions are basically the same as in Example 1, except that the acetic acid-hydrogen peroxide concentration is 80% (v / v) in the acetic acid hydrogen peroxide pretreatment, and the pretreatment solution is used repeatedly 4 times.

[0054] The content of poplaric acid-insoluble lignin pretreated by acetic acid-hydrogen peroxide decreased from 24.4% to 0.52% (removal rate was 98.8%), the yield of enzymatic hydrolysis of glucose was 84.7%, and the yield of xylose was 99.5%.

[0055] The content of poplaric acid-insoluble lignin pretreated by the first pretreatment waste liquid was reduced to 2.9% (removal rate was 92.6%), the yield of glucose by enzymatic hydrolysis was 91.4%, and the yield of xylose was 89.8%.

[0056] The content of poplaric acid-insoluble lignin pretreated by the second pretreatment waste liquid was 3.8% (removal rate was 89.7%), the yield of enzymatic hydrolysis of glucose was 90.5%, and the yield of xylose was 86...

Embodiment 3

[0060] The pretreatment method and reaction conditions are basically the same as in Example 1, except that the temperature in the acetic acid hydrogen peroxide pretreatment is 60° C., and the pretreatment solution is used repeatedly 4 times.

[0061] The content of poplaric acid-insoluble lignin pretreated by acetic acid-hydrogen peroxide decreased from 24.4% to 0.47% (removal rate was 98.9%), the yield of enzymatic hydrolysis of glucose was 100.0%, and the yield of xylose was 98.4%.

[0062] The content of poplaric acid-insoluble lignin pretreated by the first pretreatment waste liquid used was 1.7% (removal rate was 95.7%), the yield of enzymatically hydrolyzed glucose was 98.9%, and the yield of xylose was 80.3%.

[0063] The content of poplaric acid-insoluble lignin pretreated by the second pretreatment waste liquid was 6.3% (removal rate was 83.0%), the yield of glucose by enzymatic hydrolysis was 90.1%, and the yield of xylose was 80.6%.

[0064] The content of poplaric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com