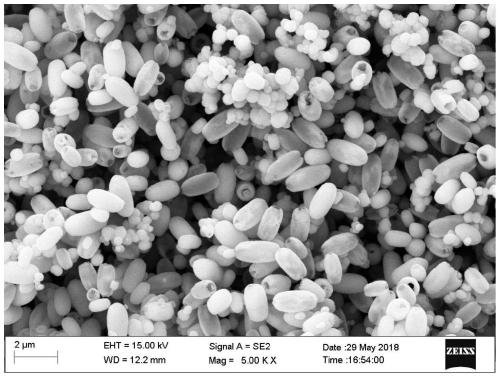

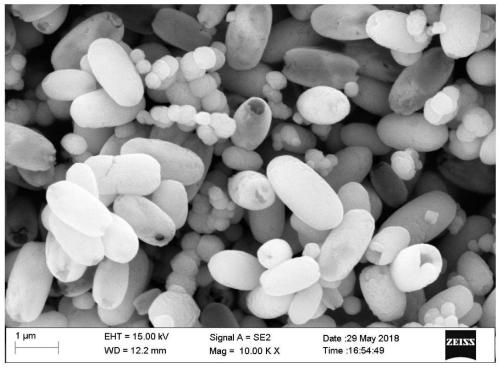

Spindle-shaped iron oxide nano material as well as preparation method and application thereof

A nano- and spindle-shaped technology of iron oxide, which is applied in the field of nanomaterials, can solve the problems of low saturation magnetization, low sensitivity, and difficulty in tumor tissue localization and retention, and achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

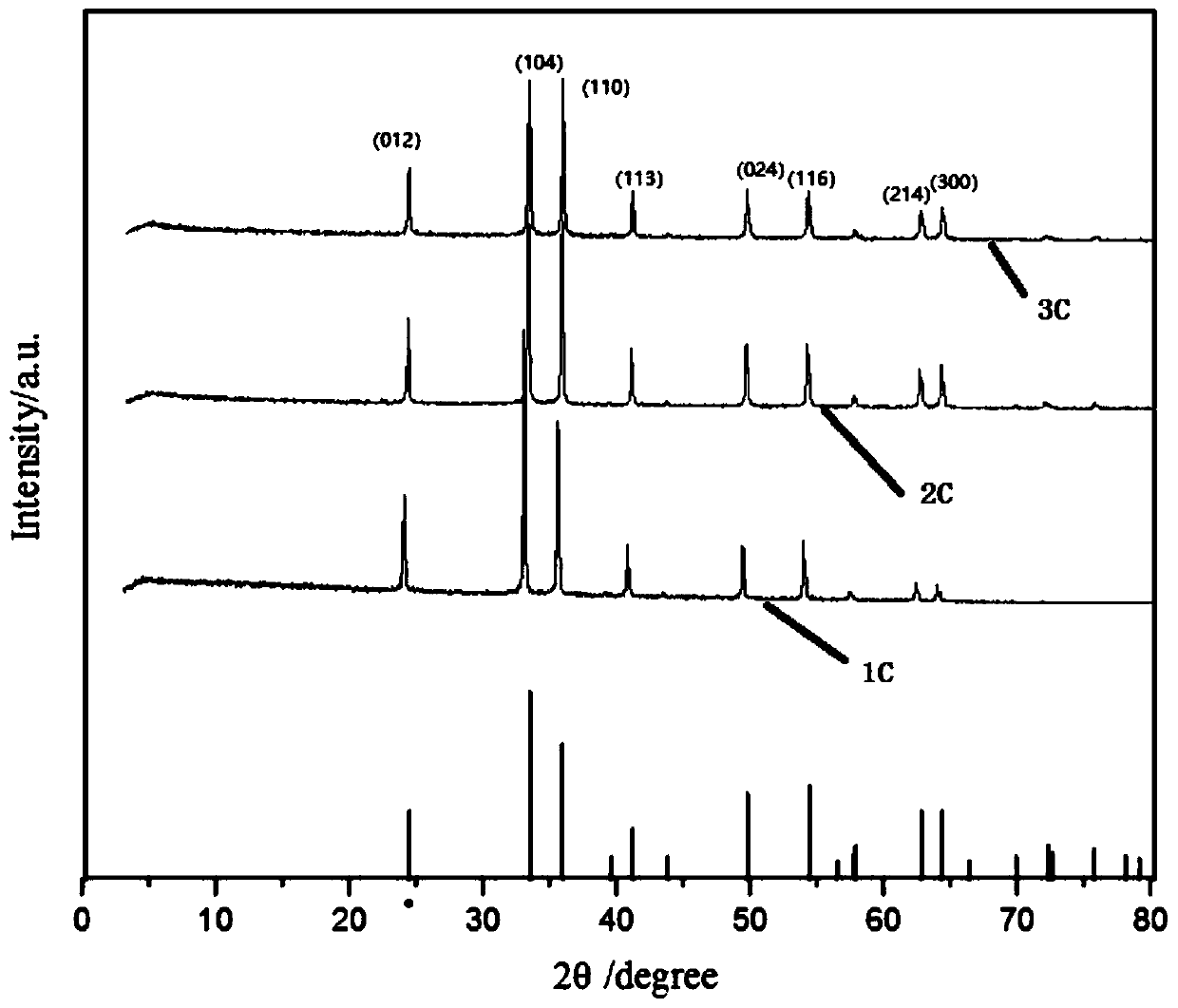

[0033] The invention provides a method for preparing a spindle-shaped iron oxide nanomaterial, comprising the following steps:

[0034] mixing phosphate compounds, sulfates, iron salts, and water, subjecting the resulting reaction solution to hydrothermal reaction, and drying to obtain a spindle-shaped iron oxide nanomaterial;

[0035] The molar ratio of the phosphate compound, sulfate and iron salt is (0.01~0.02): (1.5~1.8)×10 -4 :(5.5~9.5)×10 -4 ;

[0036] The temperature of the hydrothermal reaction is 180-220° C., and the time is 32-48 hours.

[0037] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0038]The invention mixes phosphate compound, sulfate, iron salt and water, and conducts hydrothermal reaction on the obtained reaction liquid. In the present invention, the phosphate compound is preferably sodium hydrogen phosphate, potassium hydrogen phosp...

Embodiment 1

[0050] Mix 0.0562g of sodium dihydrogen phosphate dihydrate, 0.1562g of anhydrous sodium sulfate and 10.76g of ferric chloride hexahydrate into a beaker, add a small amount of distilled water, conduct ultrasonic dissolution for 3 minutes, and put the dissolved solution into a volumetric flask , prepared into a 1000mL solution, then poured the prepared reaction solution into the reaction kettle, and packaged it; kept the packaged reaction kettle at 220°C for 48 hours; after the reaction kettle was naturally cooled to room temperature, poured out the reaction kettle For the supernatant, put the lower precipitated sample in the kettle into a beaker, and dry it at 80°C for 4 hours to obtain a sample, which is recorded as 1C.

Embodiment 2

[0052] The difference between this embodiment and Example 1 is only that the quality of sodium dihydrogen phosphate dihydrate, sodium sulfate anhydrous and ferric chloride hexahydrate is 2 times that of the corresponding raw materials in Example 1, and other conditions are the same as those in Example 1. 1. The obtained sample is designated as 2C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long trail | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com