Bacterium and virus killing coating as well as preparation method and application thereof

A coating and anti-virus technology, applied in the field of coatings, can solve the problems of inability to kill a large number of viruses and poor virus killing effect, and achieve the effect of improving efficient virus killing and enhancing timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

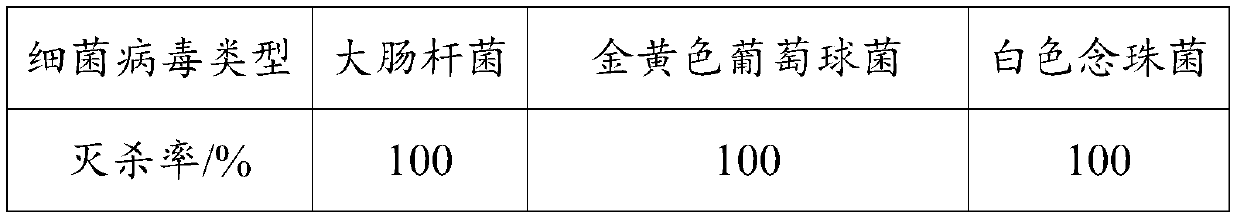

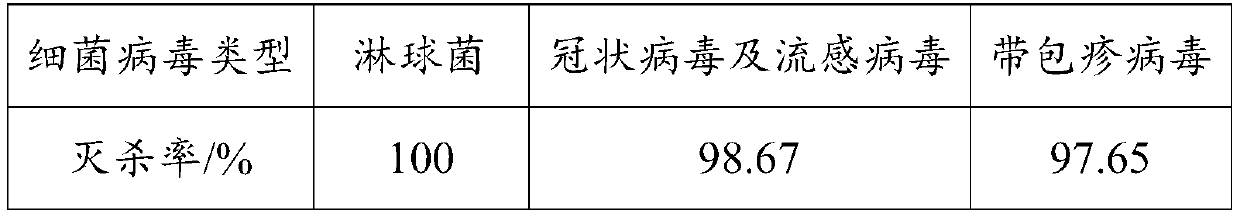

Examples

Embodiment 1

[0020] This embodiment provides a kind of sterilizing coating, and its preparation method comprises the following steps:

[0021] S1. Weigh 5 kg of water-based acrylic emulsion, 0.1 kg of thickener, 0.1 kg of dispersant, 0.1 kg of defoamer, 0.5 kg of film-forming aid, 10 kg of pigment and filler, 0.1 kg of polyhexamethylene biguanide, and 0.1 kg of metal chelating agent. kg, water 10kg, spare. Among them, the water-based acrylic emulsion is a commercially available product; the thickener is a mixture of commercially available hydroxyethyl cellulose, polyurethane thickener and alkali-swellable thickener mixed in equal mass ratio; the dispersant is a commercially available poly Carboxylic acid sodium salt; Defoamer is the mixture of commercially available silicone oil defoamer, metal soap defoamer and mineral oil defoamer mixed in equal mass ratio; Film-forming aid is commercially available alcohol ester ten 2. A mixture of ethylene glycol monobutyl ether and alcohol ester hexa...

Embodiment 2

[0024] This embodiment provides a kind of sterilizing coating, and its preparation method comprises the following steps:

[0025] S1. Weigh 40kg of water-based acrylic emulsion, 1kg of thickener, 1kg of dispersant, 1kg of defoamer, 2kg of film-forming aids, 60kg of pigments and fillers, 1kg of polyhexamethylene biguanide, 1kg of metal chelating agent, and 40kg of water, and set aside . Wherein, the water-based acrylic emulsion is a commercially available product; the thickener is a mixture of commercially available polyurethane thickener and alkali-swellable thickener mixed in equal mass ratio; the dispersant is commercially available sodium polycarboxylate; The foaming agent is a mixture of commercially available silicone oil defoamers and mineral oil defoamers mixed in equal mass ratios; the film-forming aid is a mixture of commercially available alcohol ester twelve and alcohol ester sixteen ; The pigment is a mixture of 15kg titanium dioxide, 30kg heavy calcium carbonate ...

Embodiment 3

[0028] This embodiment provides a kind of sterilizing coating, and its preparation method comprises the following steps:

[0029] S1. Weigh 10kg of water-based acrylic emulsion, 0.1kg of thickener, 0.1kg of dispersant, 0.1kg of defoamer, 0.8kg of film-forming aid, 20kg of pigment and filler, 0.1kg of polyhexamethylene biguanide, and 0.3 kg of metal chelating agent. kg, water 30kg, spare. Wherein, the aqueous acrylic emulsion is a commercially available product; the thickener is commercially available hydroxyethyl cellulose; the dispersant is a commercially available polycarboxylate sodium salt; the defoamer is a commercially available silicone oil defoamer; The auxiliary agent is commercially available alcohol ester twelve; the pigment and filler is a mixture of 10kg titanium dioxide and 10kg heavy calcium carbonate; the metal chelating agent is ethylenediaminetetraacetic acid.

[0030] S2. Dissolve polyhexamethylene biguanide in water first, then add thickener, dispersant, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com