Coating as well as preparation method and application thereof

A paint and coating technology, applied in the field of paint and its preparation, can solve the problems of weakening thermal insulation effect, easy falling off of block materials, easy cracking, etc., and achieves easy mass production and application, simple and environmentally friendly preparation method, and low raw material price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The fifth aspect of the present invention provides a method for preparing an energy-saving material, the method comprising: coating the above-mentioned coating on the surface of a substrate, and drying to obtain an energy-saving material containing the coating.

[0068] In some embodiments of the present invention, there is no limit to the drying conditions after the coating is coated on the surface of the substrate, and natural drying or drying in drying equipment can be used. Preferably, the drying temperature is 50 -100℃, the drying time is 20-24h.

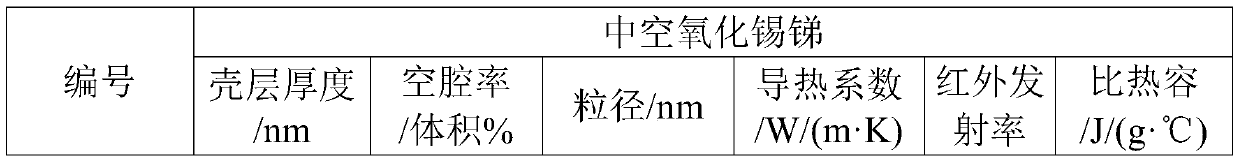

Embodiment 1

[0072] (1) 5 g of glucose and 50 mL of water were subjected to a hydrothermal reaction at 180° C. for 5 h, and the obtained product was centrifuged, washed, dried and ground to obtain a first powder.

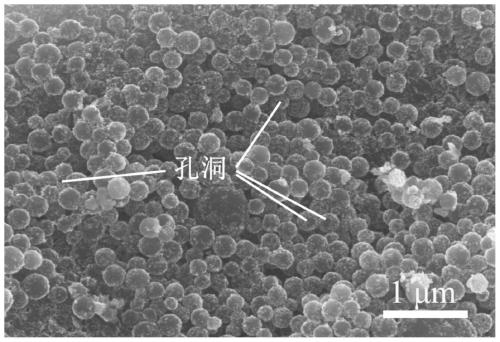

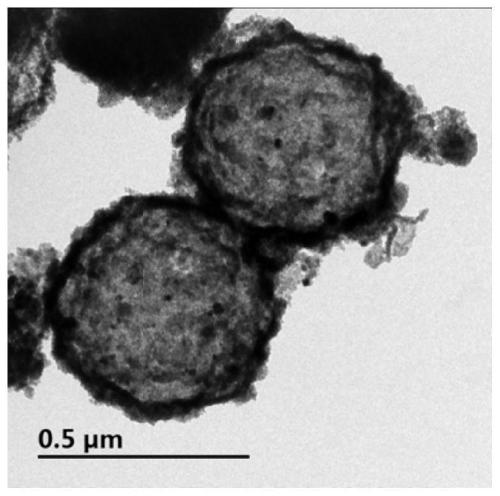

[0073] (2) Disperse 0.2g of the first powder in 30mL of ethanol, sonicate for 0.5h, magnetically stir for 0.5h, and disperse evenly to obtain A suspension; then take 4.05mmol of stannous chloride dihydrate and dissolve it in 20mL of ethanol , magnetically stirred for 1 h, then added 0.45 mmol of antimony trichloride, and continued to stir for 30 min to obtain solution B; then the A suspension was mixed with solution B, and the resulting mixed solution was subjected to a hydrothermal reaction at 180 ° C for 6 h, and the Centrifuge, wash, and dry to obtain the second powder; heat-treat the second powder at 550°C for 2h, that is, raise the temperature to 550°C at a rate of 5°C / min, keep it warm for 1h, disperse the obtained powder in ethanol, and Centrifuge at a speed of 100r / min, ...

Embodiment 2

[0078] (1) 5 g of glucose and 20 mL of water were subjected to a hydrothermal reaction at 200° C. for 3 h, and the obtained product was centrifuged, washed, dried and ground to obtain a first powder.

[0079] (2) Disperse 0.3g of the first powder in 30mL of ethanol, ultrasonicate for 1.5h, magnetically stir for 1.5h, and disperse evenly to obtain A suspension; then take 3.5mmol of stannous chloride dihydrate and dissolve it in 30mL of ethanol , magnetically stirred for 3 hours, then added 0.7 mmol of antimony trichloride, and continued to stir for 50 minutes to obtain solution B; then mixed the suspension of A and solution B, and carried out the hydrothermal reaction of the obtained mixed solution at 200 ° C for 3 hours. Centrifuge, wash, and dry to obtain the second powder; heat-treat the second powder at 550°C for 3h, that is, raise the temperature to 550°C at a speed of 5°C / min, keep it warm for 2h, disperse the obtained powder in ethanol, and Centrifuge at a speed of 100 / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com